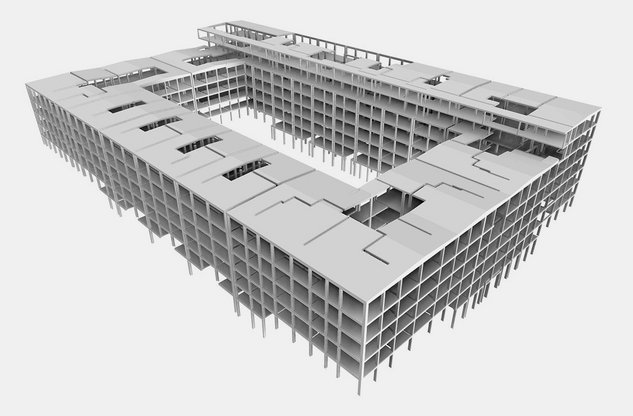

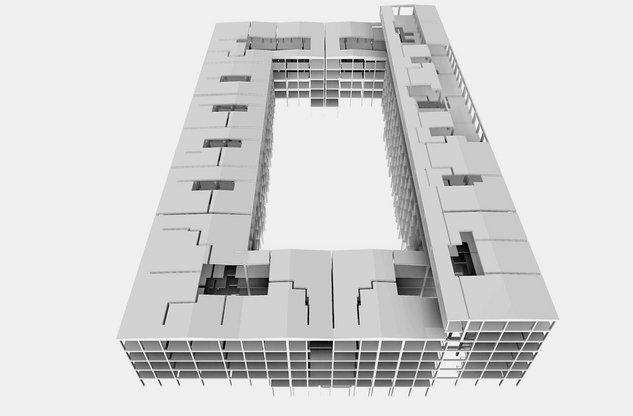

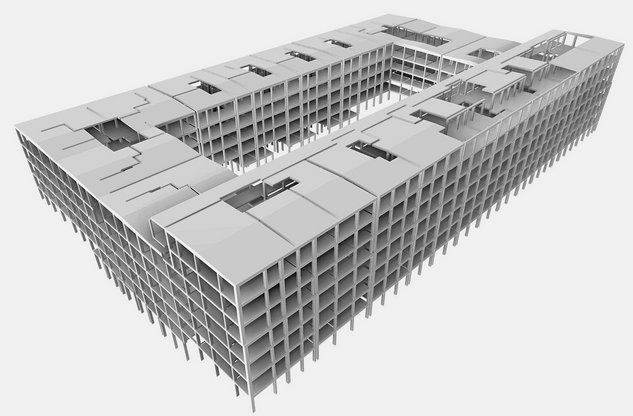

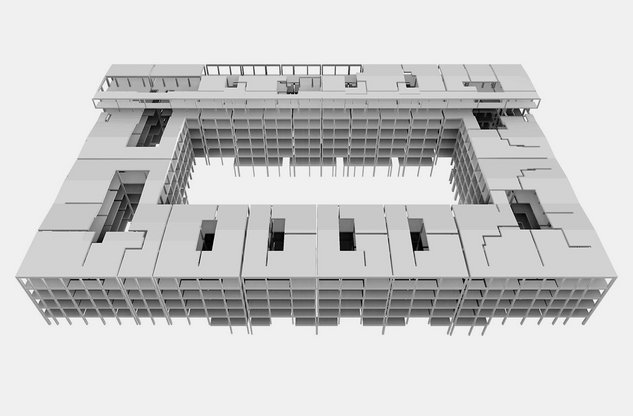

Digitalization creates a crocodile

Wood is one of the oldest and at the same time one of the most modern materials. It meets the highest requirements in terms of sustainability and cost-effectiveness, partly because wood is ideal for prefabricating building elements. Implenia makes the most of these qualities, producing timber elements in a special fabrication facility, opened in 2017, that uses computer-controlled processes and the very latest technology.

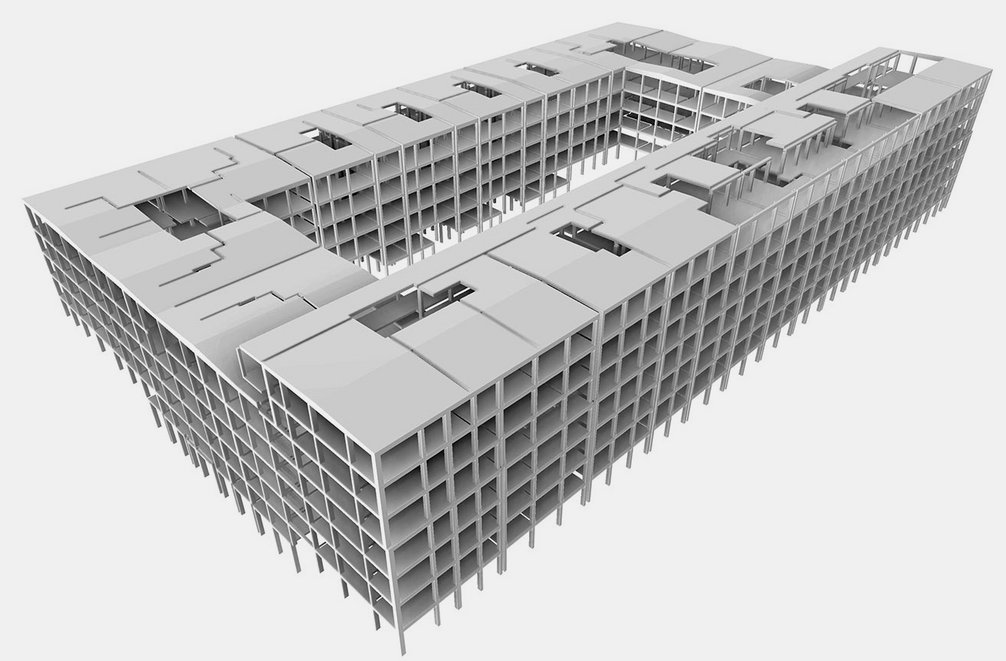

The modern production machines read all the necessary information for wooden elements directly from a three-dimensional BIM model. No wonder, then, that BIM is now being deployed for the first time for the entire planning of a timber building – “Krokodil” in the new “Lokstadt” district of Winterthur.

Even the architects who took part in the design competition submitted their proposals as BIM models. The winning model was refined and enriched with more detailed information. All the different trades integrated their execution plans into the respective models. The three-dimensional model helped everyone involved to retain a shared understanding of the building, allowing them to coordinate all the individual parts of the planning much more effectively. The model also helped the project managers monitor the expected project costs and allowed them to check very easily whether sustainability targets were being met.

During the execution phase, which the project is currently just entering, the project team expect to keep reaping the benefits of BIM technology. The key aims are to optimise logistics and assembly and to check construction progress more accurately. And will the reality match the theory? The “Krokodil” will soon show us.