Execution & Installation

UHFB - Ultra-high-performance fibre building material

UHFB, ultra-high performance fibre construction material is an alternative to total replacement of the property. Coupled with its durability, UHFB can reduce road closures and congestion times. This will become more and more important as traffic volumes increase.

Advantages of the new ultra-high performance fibre building material

A more compact and dense structure

Fine-grained amorphous silica dust as well as fine sands increase the packing density, fill the smallest cavities and lead to a very homogeneous and compact structure, i.e. a dense building material.

The low water-cement ratio

This is below 0.20, which means that the building material has significantly fewer pores.

The fibre reinforcement

The high-dosage addition of steel fibres gives the building material flexibility as well as high abrasion and post-crack resistance.

Strength, deformation capacity and durability

Switzerland's transport infrastructure is under increasing strain - the life cycle of bridges and roads is decreasing. That is why we have developed the ultra-high performance fibre construction material together with partners.

The building material has the highest mechanical strengths and durability as well as a great deformation capacity. It is also acid sulphate and frost resistant as well as vapour retardant. It is also characterised by its resistance to carbonation and mechanical abrasion.

Utra high-performance fibre building material must always be considered from production to installation.

We distinguish four different applications

- Conventional installation (pumpable UHFB) with formwork (e.g. pier reinforcements)

- Manual installation with slopes up to 12% (surfaces)

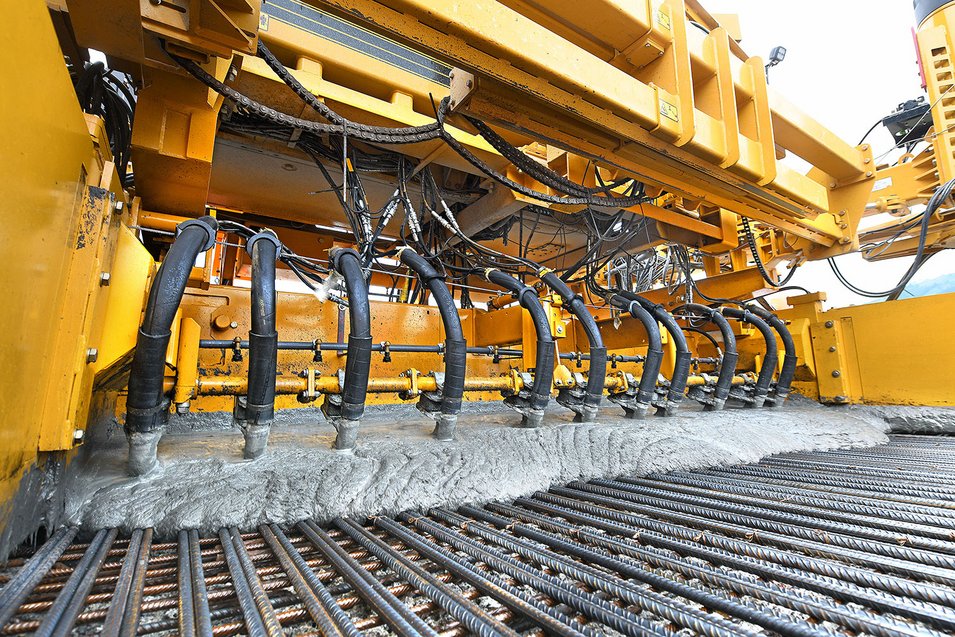

- Machined paving with concrete surface paver (Surfaces)

- Machined paving with slipform paver (Surfaces)

The different paving methods have influence on the mixing process respectively the production of Utra High Performance Fibre Building Material. We are pleased to present two different paving methods, from different projects, which have been successfully planned and executed.

Would you like detailed information?

We would be happy to send you our scientific publications.

Application examples

B-251 Habsburg Bridge, Repair, Windisch

Another innovation is a trafficable top layer of an applied UHFB/split matrix with excellent measurement values!

The client commissioned Implenia to repair the Habsburg Bridge. As a result of the transfer from the canton of Aargau to the municipality of Windisch and the condition of the structure, the Habsburg Bridge was completely renovated. The waterproofing was applied with a 2-layer composite UHFB/Splittmatrix. The abutment on the Windisch side was constructed and repaired monolithically and the bridge drainage was removed.

Rhine Kriessern-Mäder bridge in Oberriet

Machined paving with slipform paver (surfaces)

The bridge Rhein Kriessern - Mäder was built between 1977 and 1979 and is therefore about 40 years old. The static review of the bridge Rhein Kriessern - Mäder has shown that there are no structural safety reserves according to SIA 269ff (updated actions) and various components need to be strengthened. Structural reinforcement by means of Utra high-performance fibre construction material and by means of new or reinforced compression plates as well as local reinforcement of the longitudinal girders. Likewise, the cantilever slabs immediately in front of the carriageway transitions will be replaced. The mechanical paving of the UHFB with the slipform paver could be ideally used on this project and an optimal performance could be shown.

Preliminary Measures Rehabilitation Limmattaler Kreuz in Dietikon/ZH

Machine paving (two-dimensional) The client commissioned us to rehabilitate the ramp structures 013 Lucerne towards Bern and ramp structure 011 St. Gallen towards Zurich.

As a result of the staged construction method and the tight space conditions, the embankment had to be adapted for trafficability. The project author decided on a structure using UHFB, which makes use of the advantages of the building material. The UHFB was installed in two stages, a surface levelling of 4 cm and a top layer of 1 cm, sprinkled with chippings, to provide grip for the crossing. Samples and trial areas were prepared in advance to ensure that the high quality specifications of the project could be met.

Would you like more references?

We will be happy to provide you with a suitable reference list.

Summary

The solution, "Ultra High Performance Cementitious Fibre Bonded Building Material (UHFB)", allows better pressure distribution to reinforce the bridges and enables waterproofing without traditional methods such as polymer bitumen membranes. UHFB is a highly ductile, durable and dense building material that has special requirements for the production and installation process. While the building material supplier is responsible for product development in the building material laboratory, contractors are responsible for the overall concept and an efficient installation process. For this purpose, a mobile concrete plant that allows the production of UHFB on the construction site and a special slipform paver are designed.

Main advantage of UHFB: Sensible alternative to total replacement of the object

Coupled with its durability, UHFB can reduce road closures and congestion times. This will become more and more important as traffic volumes increase.

Would you like a personal field visit?

Your expert for UHFB at Implenia

Alternatively, the business card is available for download. Download VCF-Card