A highly technical construction project using green electricity

Berlin is a huge city with a growing thirst for electricity, and it needs another high voltage transmission line. Sounds simple enough, but it’s far from easy to actually build one. It would be impossible to provide this high-voltage supply to the sprawling German capital through an overhead line or a ground-level cable, so Implenia is building a tunnel beneath a long stretch of the German capital.

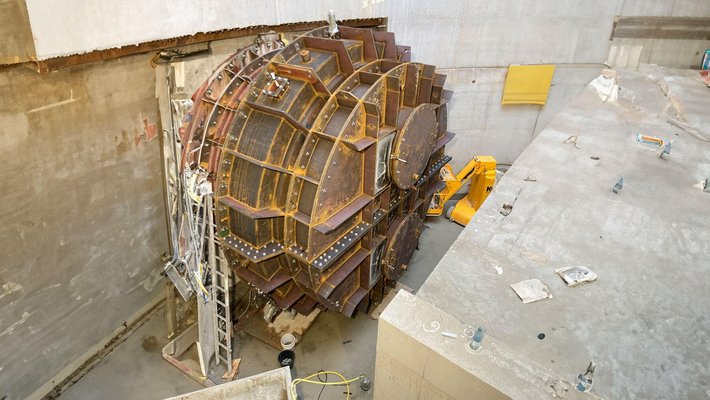

“The location of the construction site has presented us with some unusual challenges,” says Thomas Stegbauer, Head of the German Tunnel Construction Division at Implenia, who is in charge of the huge project. For one thing, the soil under Berlin is very sandy. Groundwater lies close to the surface and parts of the tunnel have to withstand substantial pressure.

Geological challenges have not stopped the project’s managers from thinking right from the start about environmental impacts. A tunnel boring machine, for example, consumes as much electricity as about 20 normal Implenia construction sites. So the team got together with construction logistics company Zeppelin Rental to work out a way of powering this exceptionally large construction site exclusively with hydroelectricity.

The cable installation is thus the first tunnelling project in Germany to run entirely on renewable energy, helping Implenia to avoid around a thousand tons of CO2 emissions per year.

Implenia’s workers are using the tunnel boring machine to drive a 6.7 kilometre tunnel, wide enough to walk through, 25 metres below the bustling city streets. A cable carrying electricity at a tension of 380,000 volts will then be laid in the tunnel.

To prevent the borehole near the cutting wheel from collapsing, Implenia is using a support fluid made of bentonite and water as a kind of protective shield. Bentonite is a natural clay, and the technique requires yet more innovative solutions involving an intermediate shaft. More on this here.

The entire underground structure, known as the “Kabeldiagonale” runs from the Charlottenburg district, through the city centre, to near Potsdamer Platz in the Mitte district. It is one of the longest power lines of this type in Europe. The underground cable will increase transmission capacity and from 2028 replace central Berlin’s existing power line.