Wientalsammelkanal

Short description

To maintain water quality and to protect the Vienna River from canalisation, the City of Vienna began constructing the Vienna Valley Sewer (known as the Wiental-sammelkanal or WSKE) in May 2003. This is one of several projects that, over a 10 year period, will form a complete underground sewerage system in Austria’s capital city.

The project

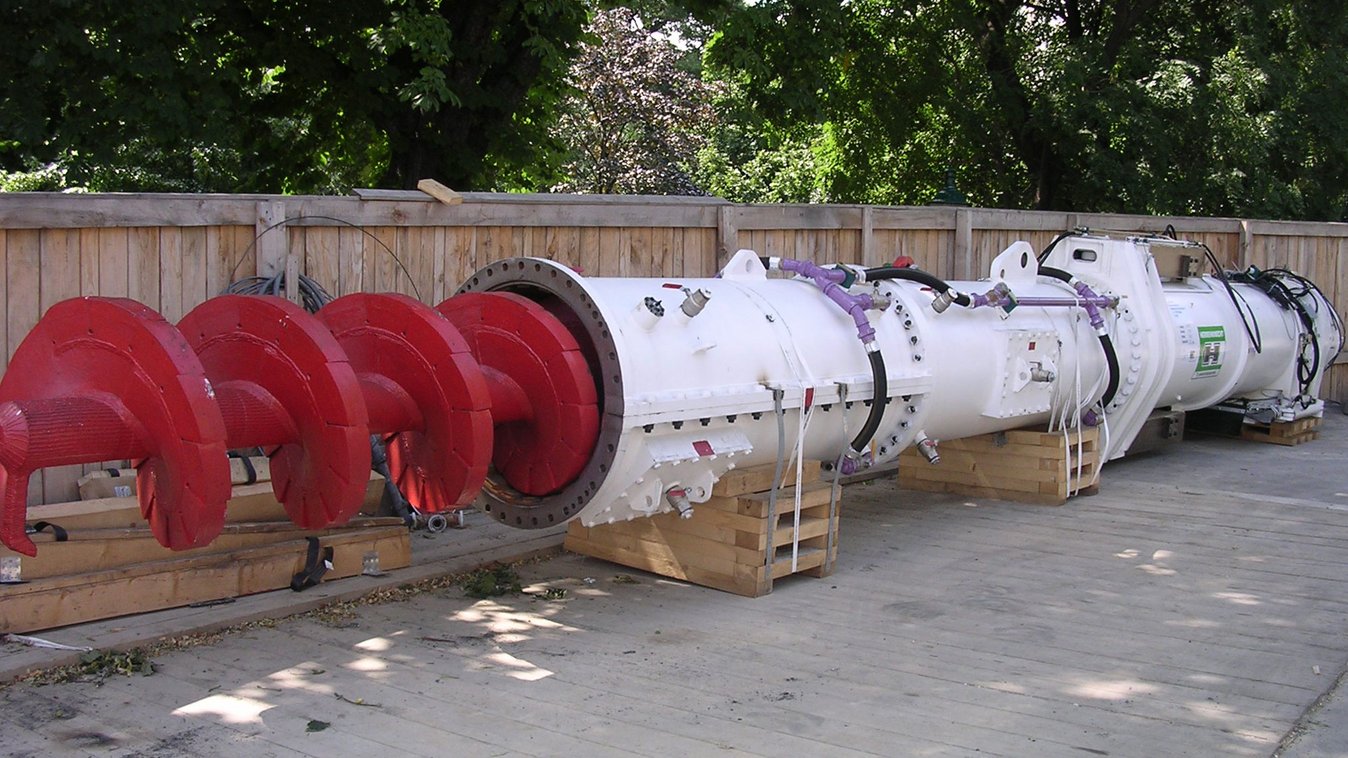

The Wientalsammelkanal runs below the Vienna River runoff ditch in the heart of the city and extends from the “Stadtpark” (City Park), across “Karlsplatz” to the “Ernst-Arnold-Park” in the “Rüdiger Hof” area. The approx. 2,600 m long tunnel has an excavated diameter of 8.60 m and was driven with an Earth Pressure Balance (EPB) shield machine. The face of the tunnel was actively supported by adding conditioning agents.

A single-layered segmental lining (5+1) with double sealing gaskets was installed. The segments were bolted together on a temporary basis; some sections were bolted together permanently. Eight shafts at depths of up to 50 m were built along the tunnel alignment. The shafts were constructed in the diaphragm wall method (roadheader diaphragm wall) and/or with bored piles. The bored piles are 2 m in diameter. The shafts were connected to the tunnel tubes by cross passages built in the mining method under the protection of high pressure stabilization and sealing units (jet grouting).

ARGE WSKE Porr Tunnelbau GmbH und Bilfinger Berger Bau GmbH:

- Porr Technobau und Umwelt AG

- Implenia Construction GmbH (former Bilfinger Berger Bau GmbH and NL TUN)

Challenges

One of the highlights of the WSKE drive was crossing below the existing Metro U1 Subway Line right in the middle of downtown Vienna. Ground cover above the tunnel roof was less than 3 m and no restrictions were placed on subway operations. Underpinning injections were used in this area to compensate for any possible ground settling. Furthermore, both tubes of the Metro U1 Subway Line were monitored by a fully automatic measuring system that tracked the current conditions of the area being driven at 15 minute intervals and visualized the results in 3D. The tight space conditions at the downtown starting shaft placed higher constraints on TBM assembly and the start-up phase as well as the logistics pertaining to supplying the drive.

Further information

Construction period / time | 2003 – 2006 / 3 years |

Work contract-construction value | 63 Mio. CHF resp. 60 Mio. € (exchange rate 1 € = 1.05 CHF), construction costs |

Billing-construction value |

|

Utilization | Sewage Canal |

Construction method | EPB TBM |

Main works + characteristics | Sewage Canal EPB TBM Ø = 8.6 m, L = 2,595 m, A = 58.1 m Single layer segmental lining (Øi = 7.5 m, d = 40 cm, 5+1, double sealing system) Crossing below the subway line U1 8 shaft constructions up to 50m depths in diaphragm wall construction or with pile walls Connecting the diversion shafts to the main tunnel either conventionally or with microtunneling (DN 1600 pipes) |

Geology | Tertiary silts, sands, clays - Hydrogeology: max. water pressure 2.5 bar - Coverage: min. 3.0 min, max. 36.0 m |

Client | Town Council of Vienna |

Planner / Site Management | Ingenieurbüro A. Pauser / |

Name of the consortium | ARGE WSKE Porr Tunnelbau GmbH und Bilfinger Berger Bau GmbH |

Consortium partner | Porr Technobau und Umwelt AG, Implenia Construction GmbH (former Bilfinger Berger Bau GmbH and NL TUN) |

Function of the contractor within the consortium | Commercial Management |

Participation on the consortium | 50 % |