Implenia Holzbau: innovation meets tradition, naturally.

About Us

Whether in element prefabrication, classic carpentry or finish carpentry and joinery, digital planning (BIM/Building Information Modelling) and LEAN processes enable us to develop detailed solutions efficiently and execute them with cost certainty.

Our production in Rümlang

#BigOnTimber

ELEMENT PREFABRICATION, CLASSIC CARPENTRY, AND FINISH CARPENTRY AND JOINERY

Our in-house element production hall manufactures wooden building elements (roofs, walls, floors and ceilings) using state-of-the-art technology. Eleven indoor cranes and nine assembly tables (including two flip tables!) support our carpenters in the construction of up to 43,000m2 of elements per year. A high degree of prefabrication makes it possible to achieve cost-accurate planning and a smooth running construction process.

FLIP TABLES

OUR FLIP TABLES

Seven gantry cranes for loads up to 5,000 kilograms and six bracket cranes for loads up to 1,600 kilograms ensure the fast transport of materials from one processing step to the next. We produce elements on a total of eight large assembly tables, two of which are so-called flip tables. Flip tables can independently overturn a wood building element with a length of up to 18 meters. This eliminates torsion in the element during flipping. Our modern equipment more efficiently produces a higher quality product, creates a safer working environment and reduces physical strain on our employees.

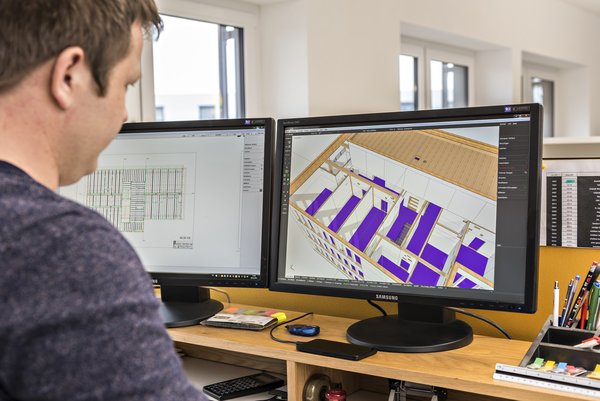

3D VISUALIZATION

3D VISUALISATION IN ASSEMBLY

Digitalization increases productivity and creates a seamless workflow from planning to the construction site. In our element prefabrication workshop, every assembly station is equipped with a computer. Screens display work plans and 3D models clarifying all necessary assembly details. Production questions get answers right at the workstation. Digital work flows also support our quality management: we know who produced what, when and how.

CLOSE PARTNERS

CLOSE PARTNERS, QUICK SOLUTIONS

In our workshop, not just production processes are efficient. Our planning offices sit directly above our production halls. Planners, managers and carpenters discuss changes face-to-face, finding the best solutions as quickly as possible.

Project Excellence/Sustainability

Excellent environmental balance

IMPLENIA HOLZBAU: PURE SUSTAINABILITY

Adhering to principles of Project Excellence & Services, Implenia Holzbau supports your commitment to sustainability.

Wood as a building material brings ecological advantages:

Compared to other building materials, the use of wood as a structural material prevents between 15% and 30% of greenhouse gas emissions.

Wood maintains a warm surface temperature. This makes every wooden building cozy.

Wood improves the indoor climate. It creates a balancing effect by absorbing and releasing humidity.

Wood is a lightweight building material – the perfect solution for additions and roof construction.

Wood is renewable and sustainable, from beginning to end in the lifecycle of a building. It grows in abundance is recyclable.

Übrigens:

Implenia has an up-to-date Sustainability Report. Here you can find out about the latest status of our commitment at any time.

Networked and committed

NETWORKED AND COMMITTED

Seven bridge cranes for loads up to 5,000 kilograms and six bracket cranes for loads up to 1,600 kilograms ensure fast transport between the individual work steps. The elements are produced on a total of eight large assembly tables. Two of them are so-called turning tables that can independently turn wooden elements up to 18 metres long. This means that no torsion can occur in the element. The physical strain on the employees is reduced to a minimum with this infrastructure.

Networked and committed

Association memberships

DEEPLY CONNECTED: OUR ASSOCIATION MEMBERSHIPS

Implenia is committed to wood as a building material and to its sustainable management, production and use. We are a proud member of the following associations:

- Timber Construction Switzerland : https://www.holzbau-schweiz.ch/de/

- Lignum Forestry and Woodworking Industry Switzerland : https://www.lignum.ch/

- Association of Swiss Joiners and Furniture Makers : https://vssm.abacuscity.ch/de/home

- Master Joiners Association: http://www.schreiner-zh.ch/

- Association of Swiss Door Makers : http://www.tueren.ch/

Did you know?

Sustainability is part of our program.

In Implenia-owned development projects, we build only with wood and wood-based materials that carry the FSC, PEFC or equivalent labels and we prioritize Swiss timber whenever possible. In addition, Implenia supports the Swiss FSC organization. With our financial contributions, we are helping to implement Swiss forestry standards and to set up an online tool to improve marketing of certified wood in the construction industry.

Contact form

Favourite destinations for timber construction

Marin-Epagnier, Implenia Switzerland Ltd.

Champs-Montants 10A | 2074 Marin-Epagnier | Implenia Switzerland Ltd.

Rümlang, Implenia Switzerland Ltd.

Wibachstrasse 12 | 8153 Rümlang | Implenia Switzerland Ltd.