Impact on climate and environment

Respect for the environment

Implenia pursues ambitious environmental goals and continuously works to minimise the negative environmental impact of its construction sites. In order to reduce the entire group’s greenhouse gas emissions, its primary focus is on resource and energy consumption.

Content

Environmental management

- GRI 3-3

Implenia operates an ISO 14001-certified environmental management system. At the end of 2024, 65 percent of business units were certified under this standard. Each Implenia Division has several sustainability and environmental specialists. These experts help with implementing environmental measures on construction sites and reporting environmental incidents. Their goal is to increase energy efficiency and optimise the use of resources. They do this by improving construction processes, promoting circular economies and optimising internal waste management.

Energy and climate

CO2 emissions

- GRI 302-1

- GRI 302-3

- GRI 302-4

- GRI 305-1

- GRI 305-2

- GRI 305-3

- GRI 305-4

- GRI 305-5

In line with the Paris Climate Agreement, Implenia wants to help limit the warming of the Earth’s atmosphere to 1.5 degrees. The company’s goal is therefore not to generate any net emissions under any Scope by 2050 at the latest. Implenia also complies with the legal climate protection requirements in markets that seek to meet climate neutrality targets earlier.

With this in mind, Implenia has already made preparations for a decarbonisation strategy from 2025. The focus is on expanding Scope 3 data collection, especially in categories 1 (purchased goods and services) and 5 (operational waste). These two categories are considered the biggest levers for construction and real estate service companies because of the concrete and steel they buy, and the subsequent use of the structures they build.

Implenia’s CO2 emissions vary from year to year, because they do not depend solely on the amount of work done or on the technologies used, but also on the nature of the services customers require. It makes a difference, for example, whether our tunnellers use the drill and blast method or a tunnel boring machine, or whether projects are in particularly energy intensive phases. The construction industry – including Implenia – still does a lot of work using diesel-powered equipment and vehicles, so a transition to electric vehicles and machinery brings great potential to significantly reduce Scope-1 greenhouse gas emissions.

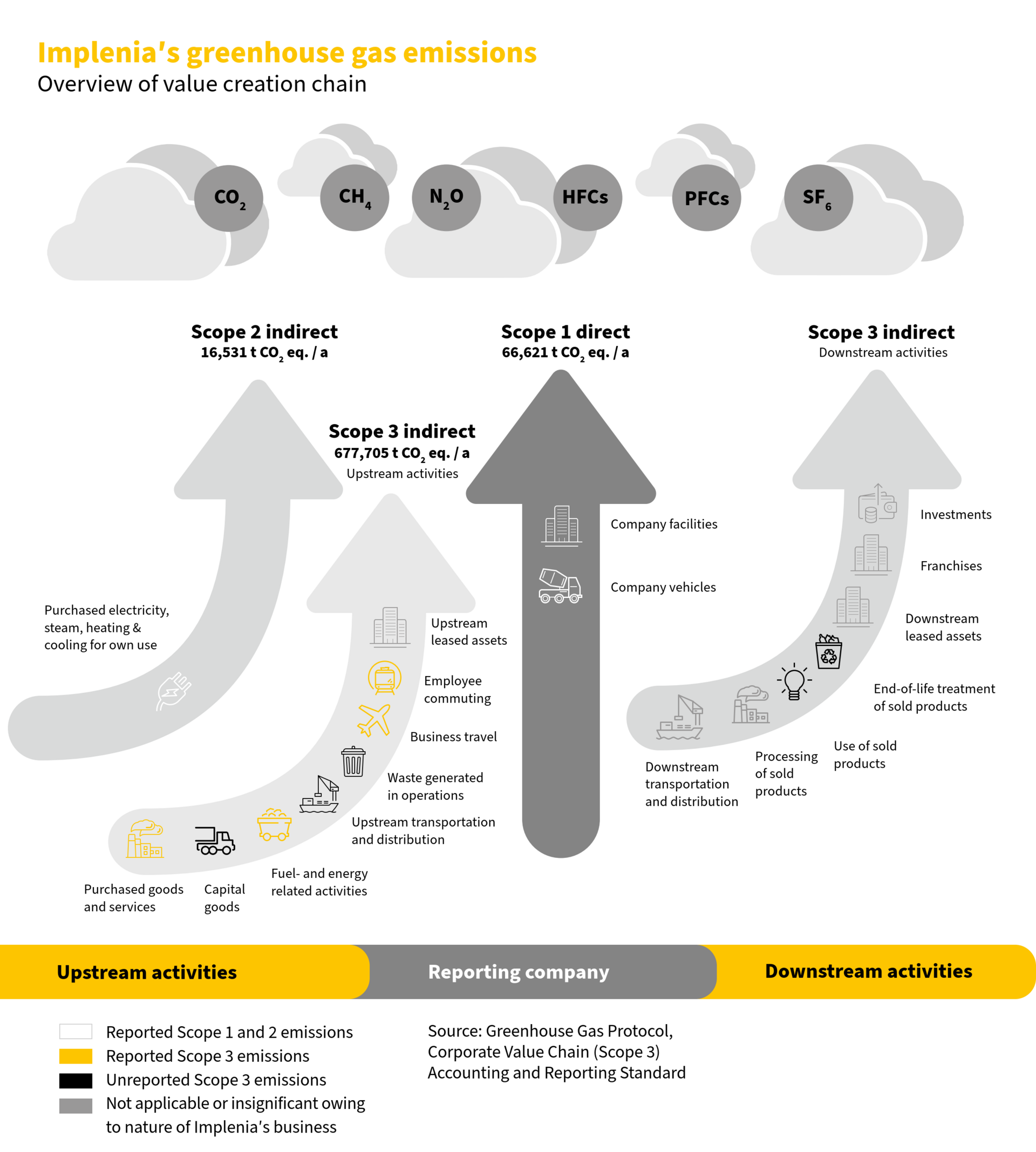

Greenhouse Gas Protocol

| Category | Definition |

|---|---|

| Scope 1 | Emissions caused directly by a company’s use of fuel in operations and transport, as well as fugitive emissions. |

| Scope 2 | Indirectly generated emissions resulting from the use of purchased electricity, steam, heating and cooling. |

| Scope 3 | All other indirect emissions in a company’s value chain caused by its activities. |

Scope 1 and 2 emissions

Implenia has been publishing its CO2 footprint for scopes 1 and 2 since 2012. This includes direct emissions from the operation of our own construction machinery, trucks, production facilities and depots (Scope 1), as well as indirect greenhouse gas emissions from grid energy like electricity and district heat (Scope 2). Data collection is continuously being expanded and now covers the entire group. This includes Switzerland, Germany, Austria, France, Sweden and Norway. Data on Implenia’s non-European activities has also been collected since 2024.

Most of Implenia’s Scope 1 and 2 greenhouse gas emissions are caused by its construction sites and production facilities. Around 65 percent of emissions are generated by diesel combustion. More construction services and processes are handled internally in Switzerland than in other countries. A country-by-country breakdown shows that 40 percent of absolute CO2 emissions are accounted for by Switzerland, followed by Germany with about 25 percent and Austria with around 15 percent. The remaining 20 percent is generated across the remaining countries.

Implenia uses 2020 as the base year for its 2025 sustainability goals. The Group emitted 21.8 tonnes of CO2 equivalents per million Swiss francs of revenue in 2020. This figure serves as the benchmark for the reduction trajectory up to end-2025.

Due to an updated data collection methodology and better data availability, the base year had to be recalculated (more on this). The recalculation was carried out using the “fixed base year” method under the GHG protocol. This means that recalculated emissions for 2024 have been added to the values of previous years.

After two consecutive years of reduction in the absolute CO2 footprint, emissions rose again in the two previous years. At 83,152 tons of CO2 equivalents in 2024, Implenia was able to reduce absolute emissions by 4.5 percent compared to the base year 2020. However, as the Group-wide revenue decreased at the same time, the target for reducing sales-adjusted emissions is not on track.

In general, Implenia's focus is moving towards more complex projects which in their nature have a more CO2-intense footprint. For example, revenues are shifting from civil engineering and specialised civil engineering to tunnel construction, which has a significant and negative impact on the footprint. Furthermore, large projects in energy-intensive phases contributed to the increase.

Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in tonnes of CO2-eq

Including recalculation of 2020-2023

Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in % by energy source for the year 2024

Revenue-adjusted greenhouse gas emissions, Implenia Global (Scopes 1+2)

in tonnes of CO2-eq / Mio. CHF

Including recalculation of 2020-2023

Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in % by usage for the year 2024

Scope 3 emissions

With regard to its target of achieving net zero by 2050, Implenia is continuously expanding its reporting on the indirect emissions generated in up- and downstream process chains (Scope 3). In particular, the sourcing, production and transportation of construction materials and the subsequent use of buildings and structures cause significant emissions, which obviously affect a construction project’s overall impact. These emissions can be many times higher than those recorded under Scope 1 and 2. Although Implenia’s influence over these processes is generally low and although it is difficult to gather the relevant information, the company is seeking to expand its database and reporting in this area in the years to come, thus laying the foundations for further CO2 reductions.

Implenia has already identified the key factors that affect the company’s CO2 footprint along the value chain. It has also assessed how relevant the fifteen Scope 3 categories are to the company’s activities based on the GHG protocol, internal and external databases and the construction industry benchmark. The following categories have been found to be relevant to Implenia:

- Category 1: Purchased goods and services

- Category 2: Capital goods

- Category 3: Fuel and energy-related activities

- Category 4: Upstream transportation and distribution

- Category 5: Waste generated in operations

- Category 6: Business travel

- Category 7: Employee commuting

- Category 11: Use of sold products

- Category 12: End-of-life treatment of sold products

Implenia has collected the following categories of data at Group level since 2022: “3 – Fuel and energy-related activities”, “6 – Business travel” and “7 –Employee commuting".

Category 1 data – “Purchased Goods and Services” – Is particularly significant in the construction industry and accounts for the majority of Scope-3 emissions (this is especially relevant to Divisions Buildings and Civil Engineering).

In 2024, Implenia also began collecting data from this category, with most emissions being caused by the consumption of concrete and steel. Specific data for the category have so far been collected in France, Norway, Austria and Sweden.

In our two largest markets, Switzerland and Germany, emissions were extrapolated from revenues generated by purchasing. These projections provide an improved insight into the magnitude of Scope-3 emissions. Implenia plans to refine the calculations next year and use more precise figures to draw more accurate conclusions.

As in the previous year, emissions in other categories were extrapolated in accordance with the Carbon Disclosure Project (CDP) and industry-specific benchmarks, and on the basis of already collected Scope-3 emissions.

Greenhouse gas emissions, Implenia Global (scope 3)

in tonnes of CO2-eq by category

Calculated Scope 3 emissions. Category 1 including concrete and steel. Further relevant categories will follow.

GREENHOUSE GAS EMISSIONS, IMPLENIA GLOBAL (SCOPE 3) - Estimation

in tonnes of CO2-eq

Estimations based on CDP, industry specific benchmarks and extrapolation of already calculated Scope 3 emissions

Energy consumption

In 2024, Implenia consumed around 415 gigawatt hours of energy. The company’s biggest energy source by far (final energy) is the diesel it uses as fuel for machinery and cars. Next come electricity and fuels that are used mainly for generating process heat in its surfacing works, such as natural gas and heating oil.

Energy usage, Implenia Global (Scope 1+2)

in MWh by energy source

Including recalculation of 2020-2023

Power consumption

Implenia aims to optimise its energy consumption wherever it can and prioritises clean energy sources. An analysis in 2023 found that 85 percent of the electricity purchased in Switzerland came from renewable sources. In order to report overall electricity consumption as 100 percent renewable, the remaining 15 percent was covered by purchasing certificates of origin from hydropower.

Implenia Germany uses hydropower certificates of origin for the electricity consumption at its construction sites and offices. In Sweden, Implenia also supplies all its construction projects in this way. In Norway, certificates of origin are being purchased for certain projects that account for around 65 percent of consumption. Implenia Austria gets 100 percent of its electricity from renewable sources or covers this with guarantees of origin.

In total, around 90 percent of the electricity consumed by Implenia comes from renewable sources or is offset by certificates of origin.

Since 2022, in line with the Greenhouse Gas Protocol, Implenia has reported Scope 2 emissions using the market-based method1 as well as the location-based method2.

1 Market-based figures including certificates of origin and emission factors of the electricity suppliers where available

2 Location-based figures calculated using country-specific emission factors given by the International Energy Agency (IEA)

Greenhouse gas emissions electricity, Implenia Global

market-based versus location-based for the year 2024 in tonnes of CO2-eq

Electricity usage, Implenia Global

in % renewable energy for the year 2024

As well as predominantly using clean electricity, Implenia also harnesses its buildings to generate its own electric power. Photovoltaic systems on the roofs of its Swiss yards near Satigny (GE), Vétroz (VS) and Schattdorf (UR), as well as at the Ecublens asphalt plant (VD) have been supplying solar power for years. The 2,500 square metres of photovoltaic modules on the roof of the Ecublens plant, for example, generate almost half a gigawatt hour of electricity per year. Since 2024, around 450 megawatt hours of solar power have also been produced annually at the asphalt production plant in Satigny.

In Germany, a solar power system on the roofs of Implenia’s subsidiary BBV Systems GmbH in Bobenheim-Roxheim (RP) produces over 300 megawatt hours of electricity per year. Almost half the energy generated is consumed on site.

Containers on construction sites provide a new option for solar power production. Implenia generated 300 megawatt hours of electricity from these in Norway in 2024 (read more).

In total, solar systems on Implenia’s own properties generate almost 2 gigawatt hours of green electricity per year. The target for end-2025 is to generate three gigawatt hours of solar power a year. A shift from owned to rented locations makes this goal challenging to achieve.

PV electricity generated, Implenia Global

in kWh

Examples for measures to reduce energy and CO2 emissions

Energy efficiency in yards

Implenia runs 18 large yards across Europe. They function primarily as repair and maintenance centres and material storage depots. But many of these sites also have office premises. Running these complexes, some of which are very large, requires a lot of heat and electricity.

The yards are always looking to implement specific energy-efficiency measures. In 2024, for example, yards in Germany converted some of their lighting to LEDs, set up charging points for electric vehicles, procured electric tools and machinery, and installed photovoltaic modules on construction containers.

Transportation by conveyor belt at the Mont Cenis base tunnel

Implenia is involved in the construction of a 57.5-kilometre tunnel for a new high-speed railway line between Lyon and Turin. A conveyor belt designed to transport the enormous quantities of excavated material came into operation in April 2024. This transports the material directly and efficiently from the tunnel portal, cutting CO2 emissions, avoiding the need for trucks on the roads, and reducing various environmental impacts such as dust, noise and water consumption for road cleaning. Another advantage of the conveyor belt is that the excavated material can be processed directly at source by a crusher and stored in this state.

Innovative hybrid reinforcement in the new Gotthard tunnel

While building the second road tunnel through the Gotthard, Implenia suggested and then successfully implemented an innovative solution that saves around 9,200 tonnes of CO₂. Instead of the conventional reinforcement rods made of pure steel, a hybrid made of steel and fibres was used to reinforce the tubbing segments. This innovation reduced steel consumption from 115 to 62 kilograms per cubic metre, resulting in a saving of around 9,000 tonnes of CO₂ in steel production alone. Furthermore, the hybrid design increases the quality and service life of the segments and reduces overall costs. Other CO₂ savings result from reduced construction times, optimised transport processes and lower processing costs.

Optimised processes in a noise abatement project

The LSW Landstuhl joint venture is building noise abatement walls for Deutsche Bahn along the railway line between Homburg (Saar) and Ludwigshafen (Rhine). In its function as the joint venture’s technical manager, Implenia Civil & Special Foundations critically examined the client's construction concept during the preparatory phase and optimised it through additional analyses, structural planning investigations and subsoil excavations.

These modifications resulted in lower construction costs, and enabled savings of 420 tonnes of CO₂. The optimised construction process played a major role here, removing the need for three excavators with a total of 810 operating hours. Excavated material, and concrete and steel consumption were also reduced.

Circular economy

- GRI 301-2

- GRI 301-3

To become more sustainable, the economy as a whole has to move away from linear production chains and start thinking in cycles. In concrete terms, products should not be destroyed or deposited in landfills after use. Instead, the materials contained in these products should wherever possible be recovered, reprocessed and returned to the production cycle as secondary raw materials. The concept of “urban mining” goes one step further: when buildings are demolished, entire components are removed and reused in construction projects.

By the end of 2025 Implenia plans to develop further circular business models and use innovative methods to close its material cycles. Each business unit is working to implement specific circular principles. Implenia aims to develop and evaluate the widest possible range of practices, always with the aim of minimising material turnover and resource consumption, extending the life of built structures, and reusing or recycling building materials.

For its new construction projects, the company also wants to use ever larger amounts of secondary raw materials sourced from demolition work elsewhere. Wherever possible, Implenia already tries to ensure that at least half the concrete it uses for its own projects is recycled concrete made in a works situated close to the construction site, for example.

Gravel that Implenia excavates from building pits is – if conditions permit – immediately processed on site and used to make concrete or to backfill within the same project. This avoids waste and saves on transport. It is a particularly effective approach in tunnelling, where Implenia can use the rock it excavates to make concrete locally (Closing material cycles on site).

Excess concrete is processed into so-called “modular concrete blocks” in several Implenia projects. These are used in a variety of ways – both on and off the construction site. This practical approach to recycling ensures that raw materials are used to the full while helping to reduce waste.

Building closed cycles into product design

In order to close cycles, it is important in the long term not just to optimise the recycling process, but also to optimise product design. New products have to be manufactured in such a way that the component materials can later be separated out and sorted without excessive use of mechanical processes, energy or chemicals. In the construction industry, the use of mechanical joints, for example, makes it easier to separate and reuse individual elements subsequently. Once a component has reached the end of its life, the individual material layers can be separated from each other and returned to the cycle as secondary raw materials.

Division Real Estate is increasingly following this approach through the work done by its Real Estate Products unit. Instead of developing each project anew, Implenia looks for flexible, cost-efficient and environmentally friendly solutions and creates standardised real estate products. These products are optimised for the entire building lifecycle. They are based on prefabricated elements designed to prioritise criteria such as ease of disassembly, durability, flexibility and re-usability.

The aim is to improve both the quality and sustainability of the buildings compared to traditional construction methods, to shorten delivery times and to reduce cost uncertainties. Using a configurator, planners combine prefabricated elements with the help of parametric design methods to give customers an optimised building design very quickly (read more).

The Real Estate Products (REP) business unit has defined its own circular strategy along with a set of circular principles. These are being systematically integrated into the development and production of various products, including Green Hospitality, and the «Cabanne» (subsidised housing) and «Casitta» (best age housing) residential products. Since 2021, REP has subjected itself to external assessment by Circular Globe to measure its own progress on the road towards a circular economy. Implenia became the first company in the property sector to achieve the “Advanced” maturity level.

Implenia has been an active member of Circular Construction Catalyst 2033 (C33) since July 2024. As part of this network, the company is committed to promoting closed-loop construction in Switzerland, and to furthering the establishment of a circular economy in construction through an intensive exchange of know-how within the industry.

Waste and hazardous substances

- GRI 306-1

- GRI 306-2

Around half of Europe’s total waste is generated by the construction industry, with excavated material accounting for a significant proportion of this. Waste is an important issue at Implenia, especially when it is demolishing old buildings. New buildings also generate large amounts of waste, much of which can be recycled. In Switzerland, for example, around 70 percent of demolished materials are now recycled as high-quality secondary raw materials. 75 percent of excavated and demolished material used is actually recycled (Source: Federal Office for the Environment).

Through improved processes and good planning, Implenia optimises the quantity of waste it produces; it is working on components and processes that allow materials to be separated easily and recycled at the end of their lifetimes.

Implenia practises systematic waste management on its sites; it invests substantial resources in efforts to dispose of construction waste by type and to promote recycling. In Switzerland, for example, it uses separate containers for different waste materials, such as concrete, metal, wood and plaster. In addition, its BCL subsidiary (Building Construction Logistics GmbH) helps reduce waste and increase recycling rates on many projects – with optimised construction logistics at Implenia and as an external service provider.

Implenia has been recording volumes of waste and recycled materials in several countries for a number of years. Data collection was extended to Sweden, Norway, France and Austria in 2024. Due to the large number and complexity of projects in Switzerland and Germany, data collection is very time-consuming and cannot yet be done with total confidence, so Group-wide reporting of waste volumes is not yet possible. The goal is to record waste volumes centrally for all countries in the coming year. In order to classify different types of wastes more accurately, the Global Sustainability Team has grouped individual waste categories together and documented these broader groups in an internal policy. The following list shows the categorisation:

Waste category

- Demolition concrete

- Metals (metals and steel)

- Excavated material

- Asphalt

- Plaster

- Wood

- Plastic

- Paper and cardboard

- Oils

- Hazardous waste

- Other waste

Disposal

- Open-loop recycling

- Closed-loop recycling

- Reuse

- Burning/thermal recovery

- Composting

- Landfill

- Anaerobic fermentation

The company takes special care with hazardous materials on its sites, such as diesel, petrol, bitumen, gas cylinders, lithium batteries and spray cans. To protect people and the environment, Implenia regularly trains its construction site personnel on how to store and transport hazardous materials.

Water consumption

Building sites don’t just use solid materials like concrete, wood and composites. Water is an equally important basic material for building. It is used in great quantities for drilling, for mixing concrete, mortar and plaster, for cleaning and humidification of building elements and processes, as well as for sanitary facilities.

Careful handling of water is becoming increasingly important in the construction industry. Implenia does various things to reduce its water consumption. One of these is to use meticulous water treatment processes and another is to reuse wastewater directly on site.

Implenia has been measuring water consumption on all its construction sites in France and Sweden for several years. In 2024, around 125,000 cubic metres of water were consumed in France, of which around half were treated and reused. Consumption in Sweden was around 4,000 cubic metres. All water used on construction sites is treated in such a way that it meets all legal requirements. Water consumption has also been recorded in Austria since 2024. The first two projects recorded total consumption of 6,000 cubic metres. As well as recording consumption , the system is designed to provide valuable information about where and how water can be saved.

Implenia is working to expand reporting in the other countries as well. It is already implementing measures to ensure water is used more economically at many locations. The Voerde yard in North Rhine-Westphalia, for example, has launched a pilot project to save fresh water – using rainwater for high-pressure washing of construction equipment, machinery and drilling tools.

Biodiversity

Biodiversity – the variety of life on earth – plays a crucial role in maintaining the health and resilience of natural cycles. In addition to its ecological importance, biodiversity has economic value. The construction sector, for one, depends on nature and what it produces. At the same time, construction activity impacts natural habitats and uses valuable natural sites as locations for buildings and infrastructure.

Although biodiversity is not classified as ‘material’ in the materiality analysis at the global level, Implenia prioritises the preservation of biodiversity in its major projects, and in all its markets is guided by European and national biodiversity strategies. The company carefully assesses the ecosystems at its project sites and surrounding areas. If necessary, it takes measures to minimise impacts and protect natural habitats. Special attention is paid to species listed on the International Union for Conservation of Nature (IUCN) Red List as threatened, endangered or highly endangered.

At the E39 Lyngdal project in Norway, for example, local flower seeds were collected before the soil was removed; these will be re-sown after the project is completed and the topsoil replaced. Wildlife crossings were created and invasive non-indigenous plants were removed. Meanwhile, at the Green Village project in Geneva, about 30 percent of the site has been reserved for plants and animals. Its green areas include wetlands, wooded areas, fallow land, meadows and shrubs. Blossom and fruit trees have also been planted to improve the food base for pollinating insects, such as bees, and other species (read more).

Implenia is conscious of the great importance of biodiversity and actively sensitises its employees to this topic. Since 2024, the Sustainability Academy, Implenia’s internal continuing education platform, has offered a special module on biodiversity.

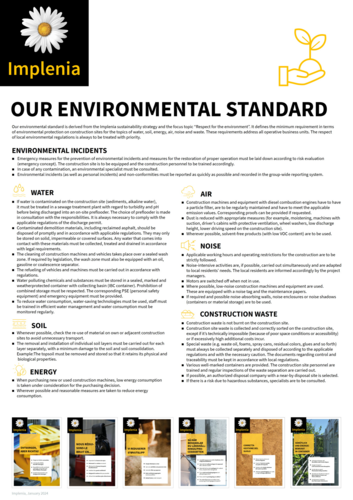

On-site environmental management

Environmental standard and environmental concept

- GRI 2-23

- GRI 2-24

An internal environmental standard has been applied across all areas of Implenia’s business since 2017. This includes Group-wide minimum requirements for waste disposal, soil protection, water treatment, noise reduction, clean air and energy consumption. These requirements – summarised on an information sheet for ease of use – must be followed by project teams on all construction sites.

In addition to its general environmental standards, Implenia applies project-specific environmental concepts to its building construction and infrastructure projects. These concepts govern the way construction sites are organised and include comprehensive sustainability criteria. Project managers are given a module-based handbook to work with, which gives them background information to help assess environmental risks correctly and take precautionary action early.

Checklists help project teams monitor energy consumption and noise pollution and develop measures to reduce them, as well as to optimise waste management and reduce impacts on air, soil and water. This makes it easier to comply with legal requirements, but also to meet additional criteria set by clients or necessitated by the desire to achieve a particular sustainability certification.

Green Construction Site guidelines

During the tendering, preparation and execution phases of a project, the “Green Construction Site” guidelines set out the central priorities for environmentally sound site management and serve as a tool for evaluating potential measures. There are five main topics: environmental protection, materials, energy, construction logistics and circular economy. Principles are formulated for each topic, showing how they translate into specific measures on the construction site.

Sensitising employees

- GRI 2-23

- GRI 2-24

Implenia regularly informs and educates employees about environmental issues, knowing that this can have a positive influence on energy and resource consumption. Three awareness-raising campaigns are carried out each year on construction sites in Switzerland, addressing key environmental issues such as soil protection, water purification, air pollution, noise reduction, waste disposal and CO2 emissions. Awareness campaigns use different measures at different levels: site personnel receive a training session, and a multilingual information poster is hung up in highly visible places on the construction site for several weeks. Project managers receive additional training and detailed documentation.

Teams receive additional training on various environmental topics. In French-speaking Switzerland, for example, these topics included environmental accidents and ecosystems. Division Civil Engineering also runs these training courses in our other European markets. Two e-learning courses were offered on such topics in 2023 (see Sustainability Academy). In Germany, Implenia sustainability experts regularly give lectures and take questions in order to deepen their colleagues’ knowledge of the 12 sustainability goals.

Office-based employees are also made aware of the issues on a regular basis. Sustainability information is posted at least once a month on the intranet or on digital noticeboards, and a sustainability newsletter is published twice a year.

Reporting of environmental incidents

A lot can happen on a construction site. Diesel or hydraulic oil could accidentally enter the ground or water, nearby roads could be polluted, or a protected tree could be damaged. To identify the cause of such incidents and learn from mistakes, the responsible managers (usually assisted by safety officers) carry out a “root-cause analysis”. Any measures that are needed can then be taken and their effectiveness monitored.

Implenia has been recording incidents on construction sites for many years, with a particular focus on accidents involving people. In 2020, the Group introduced a standardised system for all countries and divisions to investigate every type of incident in a structured manner. Environmental incidents are recorded separately by category. By the end of 2025, in line with the Group’s sustainability goals, incidents will be reported systematically in all countries and business units. Implenia intensified its awareness-raising measures in 2024. Now, for example, explanatory videos encourage employees to report environmental incidents. In 2024, 265 (2023: 247) environmental incidents were reported across the Group. This included an incident that had significant consequences: a container belonging to a joint venture partner leaked, discharging diesel into a body of water. Implenia immediately reported the incident to the authorities. A specialist company set up oil barriers and disposed of them correctly. The authorities had no complaints. Our aim is to reduce the number of serious incidents to zero.

Mobility

Implenia uses hundreds of vehicles every day. Across the Group, its cars, trucks and vans, but also excavators, rollers and other specialised vehicles and machinery consume a total of approximately 23 million litres of fuel a year.

When procuring vehicles and machinery, Implenia prioritises low-emission options. In Switzerland, Germany and Sweden, targeted internal rules on vehicle and leasing encourage the use of electric cars. More than 100 electric vehicles are already in use in Germany. Electric delivery and passenger vehicles are also deployed in France, Austria and Norway. Many offices provide their employees with e-bikes.

Wincasa’s company mobility strategy also includes electric pool vehicles. These are managed via the Urban Connect sharing platform and can be used by employees for business or private purposes on attractive terms.

The success of a switch to electric vehicles depends to a large extent on how environmentally friendly the source of electricity used to operate them is. Implenia Austria conducted an internal analysis which covered the energy mix and the CO₂ emissions of the vehicle fleet. Since the energy mix in Austria is already very green, electrification of the fleet provides an effective way to reduce CO₂. The newly procured electric vehicles cover a total of 335,000 kilometres per year, which translates into an annual saving of around 50 tonnes of CO₂ per year.

Technology has progressed to the point where alternatives to the traditional internal combustion engine are available not just for cars but also for heavy construction machinery. For example, Implenia operates several hybrid excavators in Switzerland. In Norway the company has gone a step further and has completed its first projects using purely electric-powered construction site vehicles.

Implenia Sweden, together with Finnish manufacturer Sandvik, has developed a dumper fuelled by fully biodegradable hydraulic oil for use on an underground railway construction site in Stockholm. The use of biofuels to drive construction machinery is steadily increasing. Implenia Sweden already uses 90% biofuels for its own machines.

Implenia uses incentives and awareness campaigns to encourage employees to use public transport for business travel. Employees who regularly travel by train to appointments or who do not use a company car can apply for discount cards and rail passes. Employees at head office with no company car receive a monthly mobility bonus in addition to their salary, which they can use to travel by public transport.