Innovative solutions. From a single source. For a good reason.

Special foundations

Implenia's foundation engineering experts develop complete solutions for excavations, retaining structures, deep foundations and noise barriers, from planning to execution. The service we provide to our customers is based on the specific know-how of our measurement technology, equipment technology and technical office, combined with the wealth of experience of our operational units.

Over 130 years of experience

Special civil engineering - planning, execution and sustainability

You can build on us

The combination of innovative spirit, state-of-the-art technologies and a high-performance machine park leads to solutions that will also last tomorrow. This is what our excellently trained foundation engineering experts are committed to with above-average dedication, thus setting milestones in Europe time and again. Our numerous references testify to the successful interplay of progressive construction art with many years of competence in project management.

Individual special solutions

The group-wide, close cooperation enables us to provide individual special solutions. Whether extreme conditions in difficult terrain, the development or further development of processes and technologies or the combination of several competences in one project: we have proven many times that we are a reliable partner. Our focus is always on fully meeting and reconciling the expectations of our customers in terms of quality, costs, schedules and sustainability.

We lead the way

Implenia invests considerable resources in research and development, setting high standards for itself. In close exchange with customers and partners, we are committed today to the solutions of tomorrow. This also includes our commitment to the development of national and international standards and regulations.

Quality is the top priority

We guarantee quality and sustainability

Foundation engineering stands for a wide range of technical solutions. This includes construction methods, the use of equipment and the use and further development of the materials and construction materials used. Quality assurance, occupational health and safety and sustainability are therefore high priorities for us. Our name stands for the professional execution of all construction measures.

Our demands on people, quality and the environment are clearly defined here:

Our top projects

Take a look at the diversity of our services

U5, Berlin

The U5 underground line in Berlin is being extended to extend the route coming from the east beyond Alexanderplatz to the main station. In the course of the construction measures for the traffic facilities in the central area, the tunnel section from the main station to Pariser Platz has already been constructed. In addition to the tunnel section, the underground stations Hauptbahnhof and Bundestag were also built. The contract covers the tunnel section with a length of approx. 1.6 km. Two single-track tunnels will be driven using shield tunnelling, starting at the track change facility (starting shaft). After completion, they will connect to the existing tunnel at the Brandenburger Tor underground station. In addition to the construction of the tunnels using the shield construction method, the present contract (Lot 1) includes the construction of the excavation pits and structural work for: -the Museumsinsel station including the construction of the platform area using the mining method, - the Unter den Linden station.

Read more

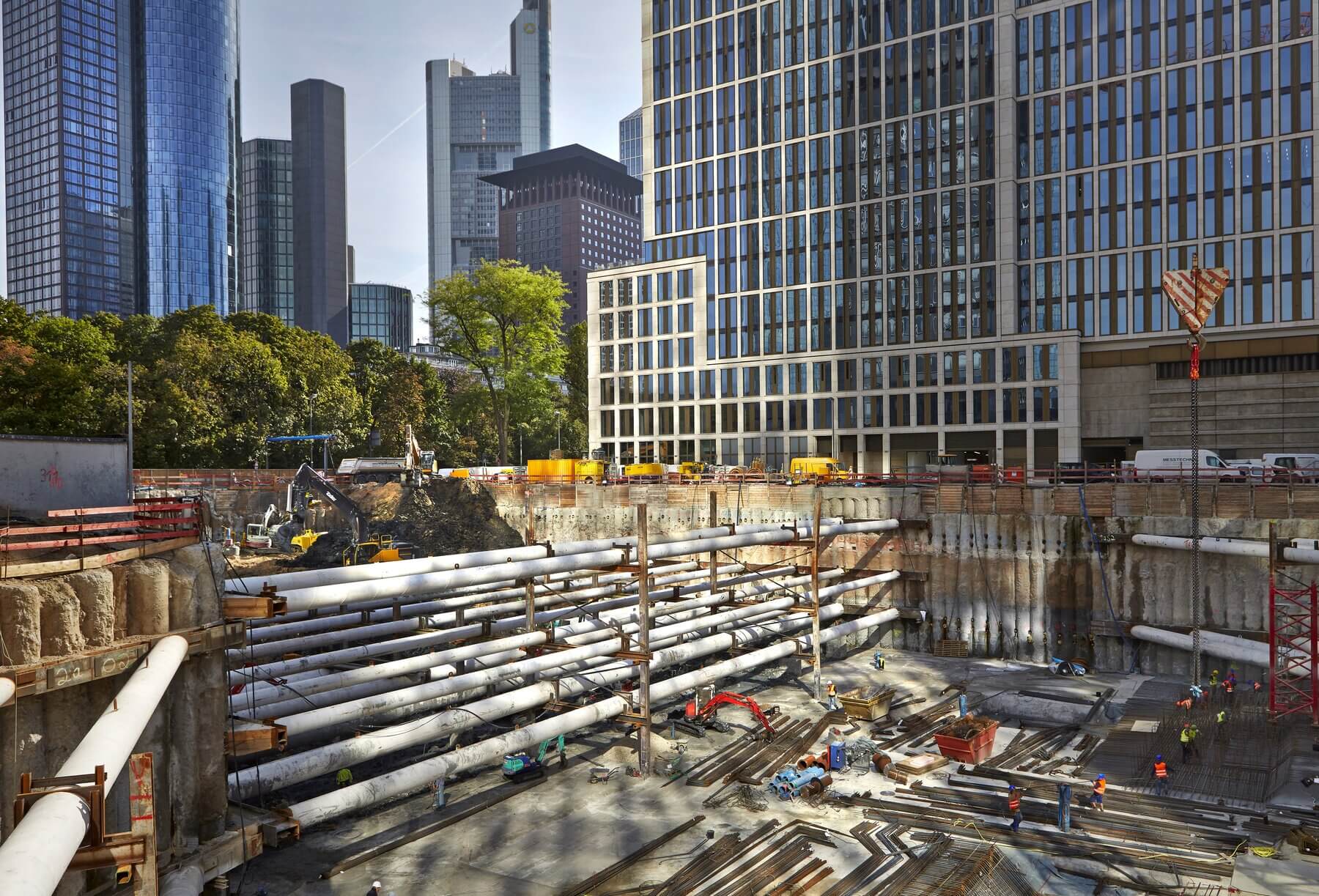

Marieninsel excavation pit, Frankfurt am Main

Between November 2015 and November 2016, the joint venture Implenia Spezialtiefbau GmbH / Robert Zeller GmbH & Co.KG constructed the Marieninsel excavation pit. The dewatering was shut down in June 2017.

The project is located on the edge of Frankfurt's banking district and comprises the two sub-projects Marienforum and Marienturm. The client of the project is Pecan Development GmbH. The Marienforum is an approximately 40m high, flat-founded building. In addition to office space, the building will house 2 restaurants.

The sister building Marieninsel, which currently holds 13th place in the high-rise ranking in Frankfurt am Main, will reach a height of 160m. It will be used primarily as an office building.

The load transfer of the high-rise tower is calculated as a combined pile and slab foundation (CPP), an essential part of which are 61 large drilled piles with a diameter of 1,500 mm. Due to the construction process, the foundation piles had to be drilled from the top edge of the ground, resulting in drilling depths of up to 62 m. The foundation piles were drilled with water ballast. The construction was carried out with water loading, including the corresponding treatment and desanding of the process water.

Marienhof stop - VE41

The large-scale 2nd Munich S-Bahn main line project consists of the sub-measures "inner-city area/tunnel" and "network supplementary measures" in the outer branches.

outer branches.

In the course of the Marienhof construction measure, the central access structure in

diaphragm wall and cover construction. The advance excavation level at approx. 3m below ground level with anchored soldier pile shoring as excavation support will be constructed in advance. From this level, the diaphragm walls and the primary supports for the temporary load transfer of the floor slabs are constructed. After

After completion of the concreting of the barrier floor slab, the excavation of the individual levels begins continuously from top to bottom. Openings in the slabs remain in order to secure the supply and disposal.

Due to the existing buildings around the excavation pit, the platforms below will be excavated under compressed air. To secure the

extensive compensatory injection measures will be carried out to secure the surrounding buildings, divisions and underground railway structures.

Home port Düsseldorf

Im Düsseldorfer Medienhafen wurde eine Baugrube für den Bau von zwei ca. 100 m hohen Wohntürmen mit Tiefgarage erstellt.

Die Implenia Spezialtiefbau GmbH erhielt den Auftrag, diese Baugrube in Schlitzwandbauweise mit Tertiärverankerung zu erstellen, wobei der obere Abschluss der Wände aus einer Trennwand zwischen Setzträgern besteht. Dies war aufgrund der Vorgabe der Stadt Düsseldorf notwendig, die oberen 2,5 m frei von Stahl und Beton zu halten. Aufgrund der beengten Lage zwischen dem Hafenbecken A und der einzigen Zufahrtsstraße, die als Sackgasse konzipiert war, wäre ein späterer Abbruch bis auf -2,5 m nicht möglich gewesen. Für die Gründung der Gebäude wurden außerdem 226 Bohrpfähle mit einer Gesamtlänge von 1.994 m hergestellt. Diese wurden im Rohbau und im Fundament verpresst.

Aufgrund der Lage konnte keine klassische Rückverankerung der bis zu ca. 10 m auskragenden Verbauwände durchgeführt werden. Die Aussteifung erfolgte daher mittels Rohraussteifungen des Groundforce-Systems mit einem Durchmesser von ca. 1,0 m und einer freitragenden Spannweite von bis zu ca. 40 m. Die Abstützung der Rohraussteifungen erfolgte mittels einer Pressschalung. Die Rohraussteifungen wurden auf Stahlgurten gelagert, die in den Eckbereichen zusätzlich mit einer Scherverankerung in der Schlitzwand versehen wurden.

Die Rohraussteifungen wurden während der Rohbauarbeiten abschnittsweise entfernt, sobald die Aussteifungsplatte unter den Rohraussteifungen hergestellt und ausreichend tragfähig war.

Während der Herstellung der Baugrube musste diese aufgrund des hohen Wasserstandes des Rheins zweimal planmäßig geflutet werden, um eine übermäßige Belastung des noch ungesicherten Baugrubenverbaus zu verhindern.

Alter Wall Hamburg

Behind the historic façades of the Alter Wall 2-32 ensemble, around 23,000 m² of modern office space and around 12,000 m² of high-quality retail space are to be created between Alsterfleet, City Hall, Rathausmarkt and the Chamber of Commerce.

A core refurbishment was carried out in houses no. 10 - 32, leaving only the listed facades facing the Alter Wall and Adolphsbrücke. In house 32, the part of the existing building required for the stability of the façades was initially retained. Subsequently, a 12-storey building ensemble was created here with 6 office, 3 retail and 4 parking storeys.

The property Alter Wall 2 - 8 was added to the list of listed buildings in 1983. The properties Alter Wall 10, 12, 20, 22 and 32 are listed as part of the ensemble Alter Wall 2 - 32, Rathausmarkt 2 as cultural monuments worthy of protection in the list of monuments. For buildings 10 - 32, a complete gutting and reconstruction behind the old facades was planned due to the poor structures and building fabric. In addition, the existing cubature of the staggered storeys was extended in parts (building 10 - 22).

Mannheim Technical Town Hall

Construction of an excavation pit and driven pile foundation for the new building of the Technical Town Hall in Mannheim.

The enclosure of the excavation pit was carried out by means of a single-layer tie-back beam shoring with timber and shotcrete infill. The girders were inserted into the ground by means of a Kelly borehole after an explosive ordnance probe had been carried out. Subsequently, the space between the girders was filled with wooden planks down to a depth of 1.50 m below ground level. The area below the 1.50 m to excavation base (approx. 4.50 m below ground level) was secured with a shotcrete shell. The shoring was anchored back with a layer of grouted anchors, each with 2 to 4 strands.

The foundation for the later structure was made by means of 635 prefabricated reinforced concrete piles driven up to 18.00 m deep into the Mannheim subsoil. The majority of these piles were driven at an angle to form 3 and 4 pile trestles. Here, too, an explosive ordnance probe was first carried out.

In addition, four foundation piles for a revolving tower crane were driven using the Kelly drilling method.

Heat storage Rostock

Stadtwerke Rostock commissioned our Erfurt office, based in Arnstadt, to build a 55 m high "thermos".

The water serves here as energy capacity so that the gas turbines used for energy conversion do not have to be shut down in the event of partial load cycles. The heated water can then be fed into a district heating network. Points awarded in the area of sustainability!

VDE 8.1 Breitengüßbach - Zapfendorf

Implenia Spezialtiefbau GmbH was commissioned with

the following positions:

- Planning of all auxiliary construction measures

- Planning of 6 retaining walls incl. formwork and

reinforcement plans for engineering

- a total of 29 substructures

- 7 bridge foundations

- 6 retaining walls as bored pile walls

- 10 abutments for 5 auxiliary bridges

- 9 sheet pile pits

- overlapped bored pile wall for tunnels

under BAB 73 in cover construction

- excavation pits with soldier pile shoring

- Foundation for approx. 9 km noise barrier

E-Powerpipe Bacharach

In the course of the energy turnaround, high-voltage power lines must be built in Germany.

be built in Germany to transport the regenerative wind energy from the wind farms to the

from the wind farms to the conurbations. Some of these are to be built as underground

underground cables. In the area of the Bacharach transformer station in Rhineland-Palatinate

Implenia is laying underground cables using the newly developed E-Power Pipe® process.

-method developed by the

Herrenknecht's newly developed E-Power Pipe® process. With a specially developed

tunnel boring machine with a bore diameter of 505 mm is used to bore six times

700 m in a curved drive. The method is to be used in future in

areas where, for example, open construction methods cannot be approved for environmental reasons.

open construction methods cannot be approved.

Career at Implenia Foundation Engineering

Whether on the construction site or in the office - we offer a top working environment for you.

Whether you are a career starter or have professional experience: take a look at our current training and job offers. We look forward to meeting you!

Locations

Implenia Spezialtiefbau finden Sie an diesen Standorten

Our customers can draw on Implenia's entire portfolio of services at all our locations. Our specialists work across locations and divisions to offer you the best solution from a single source.

FAQ: Frequently asked questions and our answers

General questions about implenia foundation engineering

In which segment is Implenia Special Civil Engineering active?

Implenia Spezialtiefbau implements technically high-quality turnkey excavations and is a reliable partner in internal and external joint ventures. Implenia Spezialtiefbau offers its customers a wide range of services, from the implementation of partial services to project implementation as a general contractor.

What services does Implenia Special Civil Engineering offer?

Implenia Spezialtiefbau offers a richly filled portfolio of technical services. This includes planning, consulting and execution. In addition, we have the advantage of being able to access our own equipment pool and have our own in-house further and new development of systems, equipment and processes.