CERN - Galerie UA 53

Short description

All for science: CERN, the European Organisation for Nuclear Research (Conseil Européen pour la Recherche Nucléaire), is one of the largest and most renowned centres for basic physics research in the world.

The project

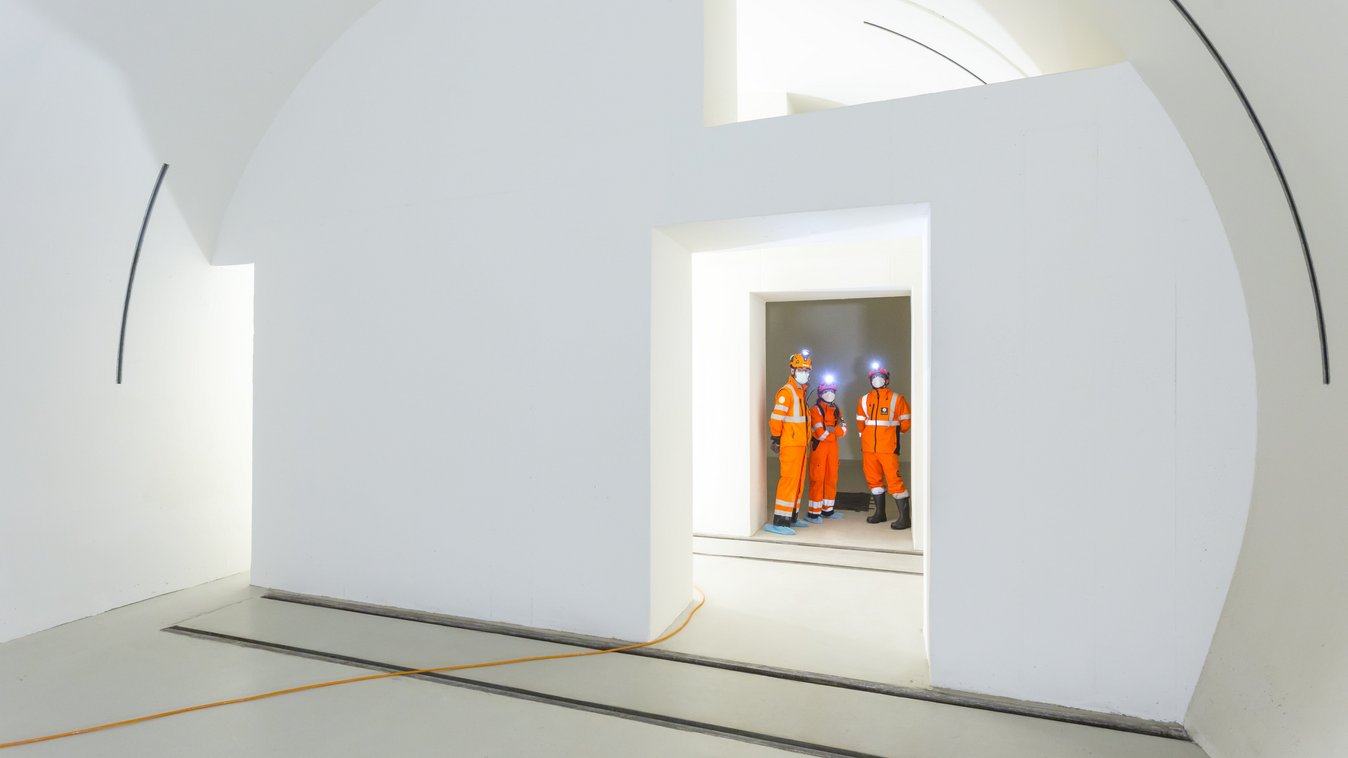

Researchers search for the fundamental laws of the universe. At CERN, the world's largest and most complex equipment is used to research the smallest components of matter: the elementary particles.Tunnelling and formwork construction work was carried out for CERN.

Services in detail

Tunnelling

The shaft and tunnels are being constructed conventionally without blasting in order to comply with the vibration values imposed by the sites operated in the immediate vicinity of CERN (CMS). This also required construction machinery to be equipped with electric motors. On the one hand, this reduces vibrations and, on the other hand, no exhaust fumes are produced.

The entire logistics of the construction site are handled by an overhead travelling crane, which is located above the access shaft in a noise protection enclosure and enables safe access for the workers as well as the transport and supply of the large machines, supplies, concrete and large formwork tools.

Formwork

Implenia Formwork Construction supported with the construction of an additional observation point on the ring of the existing particle accelerator at CERN.

- 2 vertical shafts with accesses and chambers to the main tube.

- 4 cut-and-cover tunnels from 15.0m to 55.0m in length, 2 of which have chambers at the end.

- Two tunnel formwork cars with two different diameters. Divisible in the middle to be able to realise widenings in width and height.

- Production of the formwork for the end walls of the respective tunnels, spectacle walls for the various expansions, intersections of tunnel tubes with different cross-sections (shifters) with special formwork.

- Partition wall formwork for the demarcation of the main tube with the newly constructed side tubes.

Each formwork had to meet the highest exposed concrete requirements.

- Tunnel formwork carriage with PERI Variokit (provision of formwork: approx. 80 -120 m²)

- Special formwork for shield and spectacle walls (single-sided with Trio Aluminium)

- Special formwork for upstands and vaults

- Accesses by means of TG 60 stair tower

- Trio - Aluminium formwork for shafts and vaults

- Special formwork for intersections of the tunnel tubes (shifters)

- Special formwork for the Sonic Boom

TUNNELLING CHALLENGES

Implenia France starts its activities in France with demanding challenges:

Technically, by complying with strict vibration values

Logistically, with access through a single enclosed shaft.

Planning, with tight deadlines for surface and underground works

Environmentally friendly, with strict excavation management