Groundhog Alpha

Swissloop Tunneling

Swissloop Tunneling is a student association at ETH Zurich and researches new solutions for the tunnelling industry. 2021, the team built their first tunnel boring machine and named it "Groundhog Alpha" after the local tunnel-building marmot.

Prototype with unique control mechanism

More maneuverable than conventional machines

In addition, the innovative tunnel lining system allows the tunnel tube to be manufactured using the 3D printing process. This novel process aims at continuous production, free of prefabricated elements.

Swissloop Tunneling was invited to Elon Musk's Not-A-Boring Competition as one of twelve teams out of 400 initial applicants. At the finals of the competition in Las Vegas in the summer of 2021, the students won the Innovation and Design Award and second place with "Groundhog Alpha".

Groundhog Alpha

The prototype

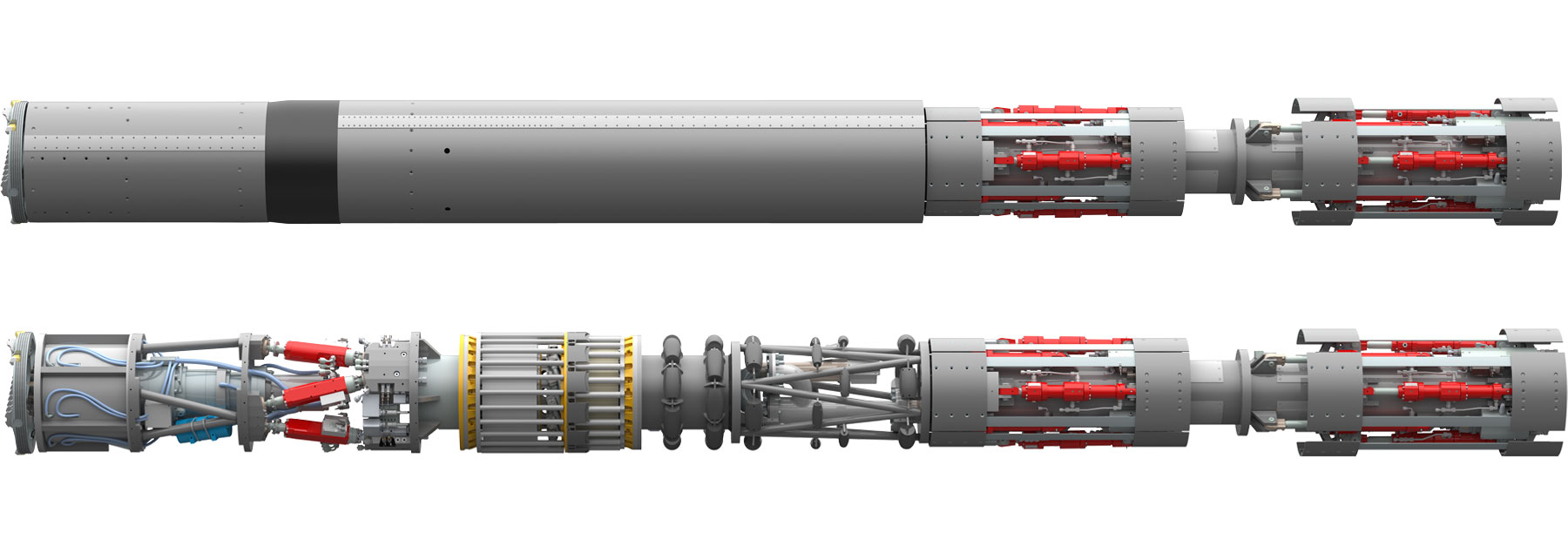

Over the course of the last year, the students designed, constructed and tested "Groundhog Alpha". In doing so, the association deliberately pursued a very innovative approach. Swissloop Tunneling is convinced that this novel approach will be the basis for future tunneling solutions.

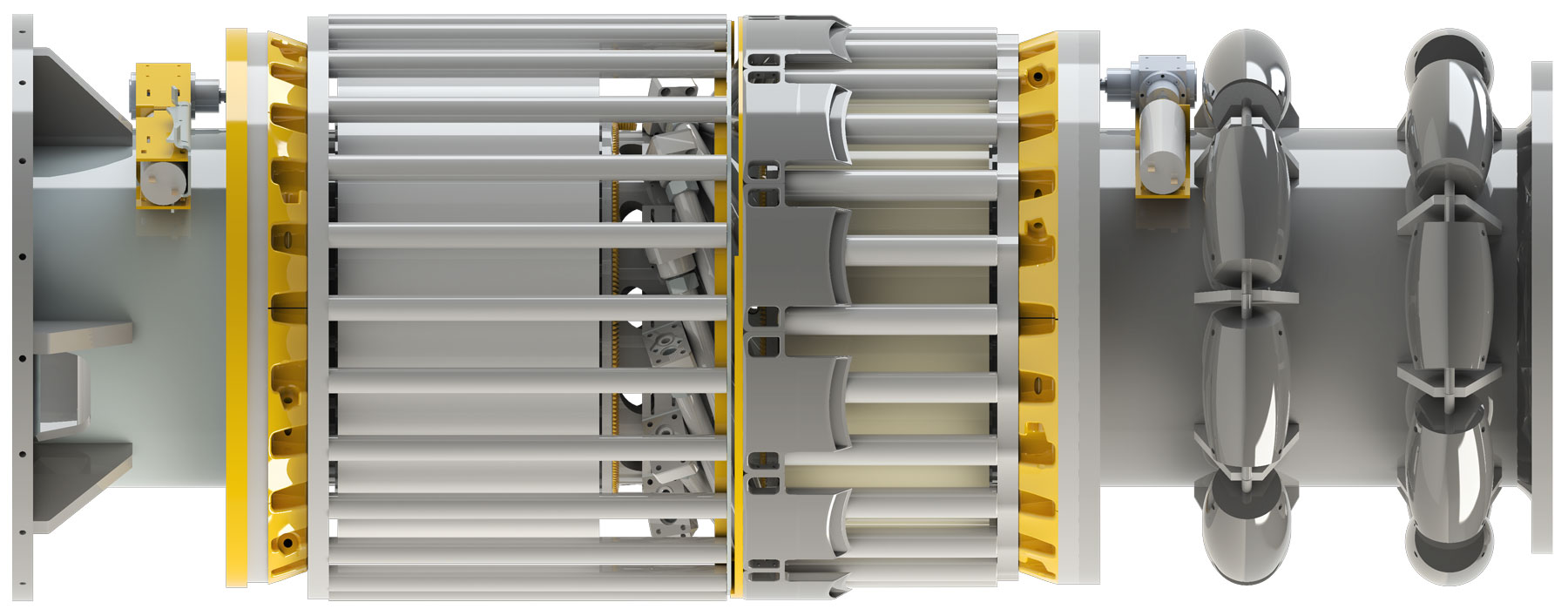

The prototype has the following dimensions and subsystems:

- Length: 7 m

- Mass: 2.5 t

- Diameter: 0.56 m

- Driving force: max. 200 kN

- Rotation speed of the drill head: 27 rpm

- Planned speed: 0.5 cm/s

Dismantling and removal

Crushing of the material with an own design

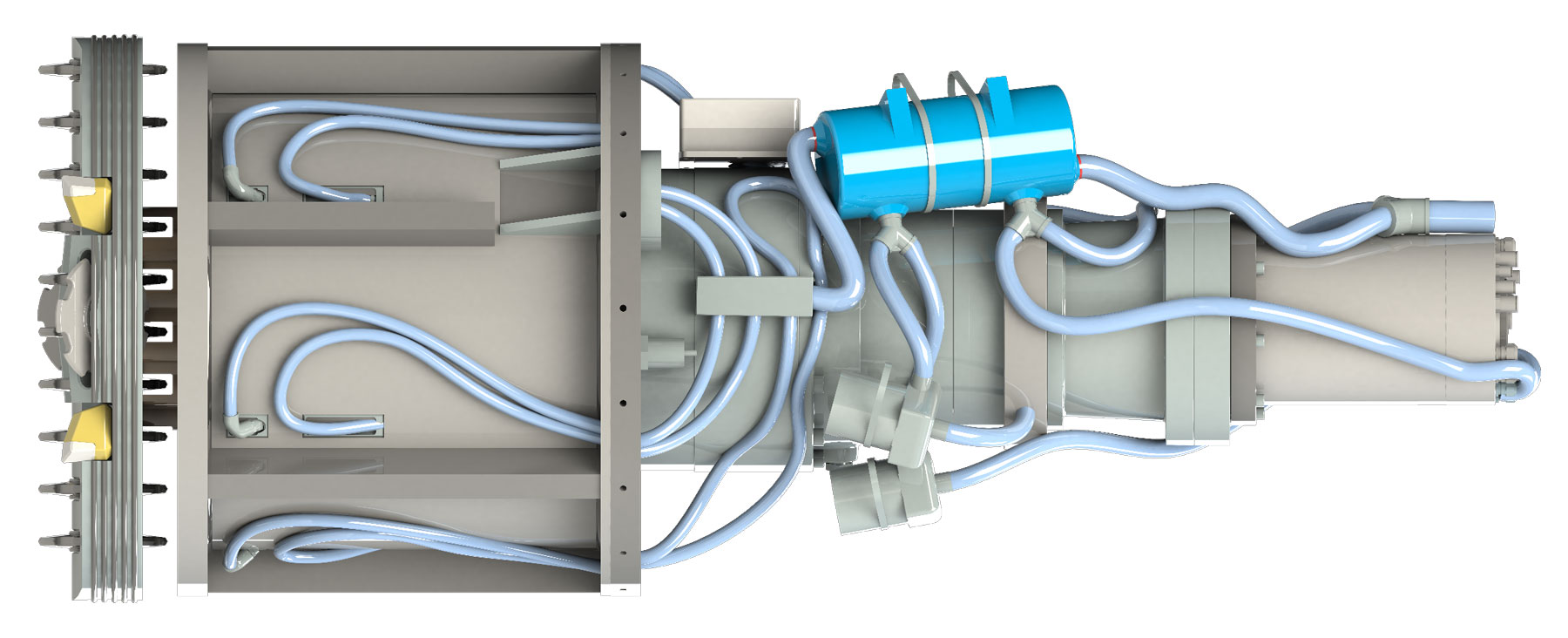

The cutting wheel is adapted to different geologies and is used to loosen the subsoil from the working face. A cone crusher in the erosion chamber is then used to crush larger rock fragments to approx. 1-2 cm. The cone crusher is assisted by high-pressure water jets. In the final step, the slag is extracted from the erosion chamber by a Venturi vacuum pump.

Control

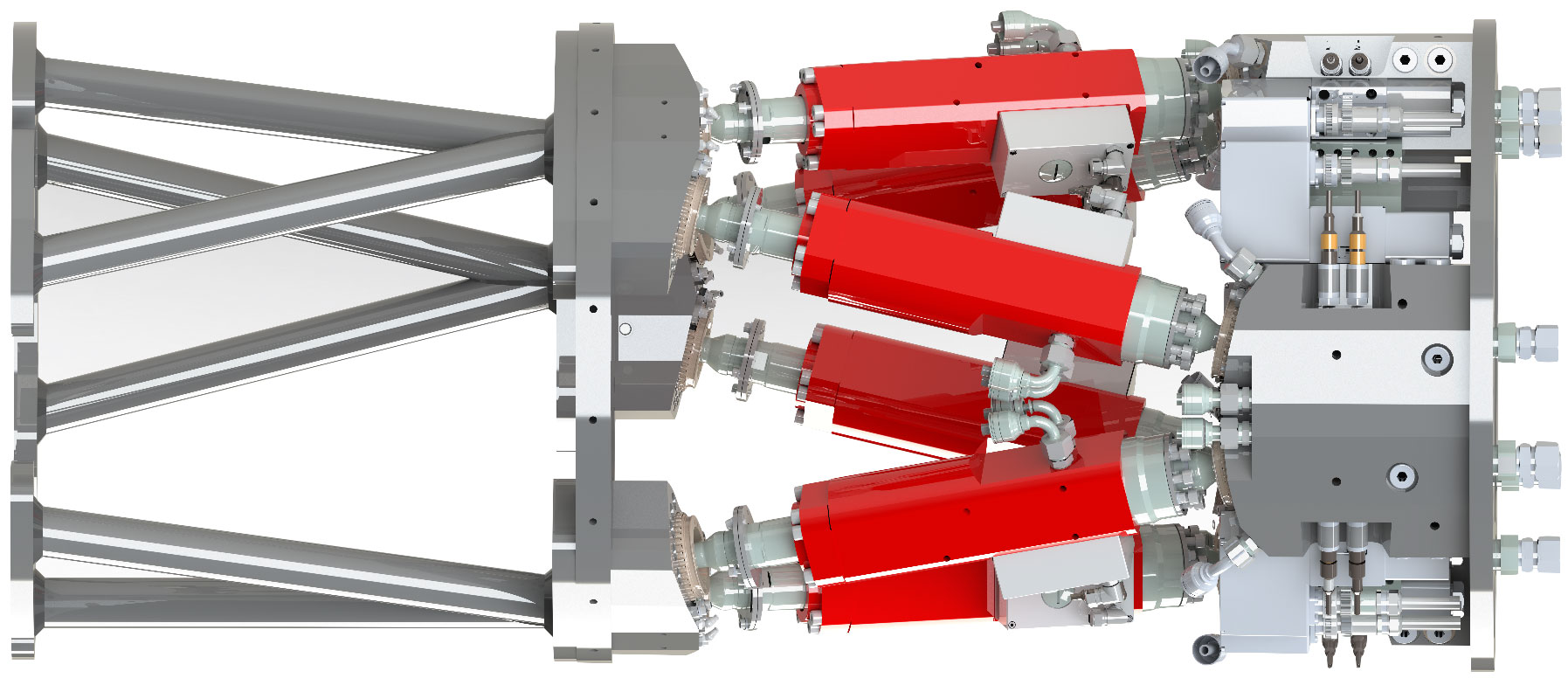

Maneuverability due to 6 precision cylinders

A customized hydraulic hexapod system was designed for the control system. The six precision hydraulic cylinders allow the drill head six degrees of freedom. Additionally, in emergency situations, the hydraulic system can be used like a jackhammer, where the entire drill head is vibrated, with a frequency of up to 20 Hz.

Tunnel expansion

Novel in-situ production of the tunnel lining

Advance

Continuous propulsion through an ingenious mechanism

The collaboration between Implenia and Swissloop Tunneling is entering its second round this year.

Miguel Nunes, Board member at Swissloop Tunneling and trainee at Implenia.

Vision

Next challenge: Not-a-Boring Competition 2023 in Austin, TX

The Swissloop Tunneling Team is preparing for the new edition of Elon Musk's Not-a-Boring Competition, which will take place in Austin, Texas, in early 2023. For this, the tunnel boring machine will be extensively tested and further developed. With this new iteration, the goal is to celebrate success at the competition one more time.

In the long term, however, Swissloop Tunneling wants to see itself not only as a competition team, but also as a research platform for motivated students. The development of innovative (micro) tunnel solutions is to be promoted. Implenia is the right partner for this!