Impact on climate and environment

Respect for the environment

Implenia pursues ambitious environmental goals and strives to reduce the environmental impact of its construction sites. In particular, it aims to reduce the entire Group’s resource and energy consumption – and thus its greenhouse gas emissions – continuously.

Content

Environmental management

GRI 3-3

Implenia operates an ISO 14001-certified environmental management system. At the end of 2022, 87% of business units were certified under this standard. Each division has several sustainability and environmental specialists. Supported by the Global Sustainability team, these experts are responsible for implementing environmental measures on construction sites, reporting environmental incidents, increasing energy efficiency and optimising the use of resources – for example, by promoting recycling. Over the years, Implenia has significantly improved environmental management on its construction sites. It aims to extend optimised environmental management to all projects by 2025 and to avoid accidents that damage the environment.

Implenia systematically collects environmental data relating to its production facilities, yards, office properties and construction sites, as well as to its self-developed projects and to mobility. The company logs where energy is being consumed and now also takes a closer look at material flows, from the extraction of raw materials to the finished building.

A web-based software package allows the company to capture energy and emissions data continuously from various sources, as well as to produce specific analyses to help monitor outcomes. Since the introduction of this software, the quality and regional detail of the data has improved significantly. The company is constantly working to further optimise its collection and processing of environmental data.

Energy and climate

CO2 Emissions

GRI 302-1, 302-3, 302-4, 305-1, 305-2, 305-3, 305-4, 305-5

Implenia’s CO2 emissions vary from year to year, because they do not depend solely on the amount of work done or on the technologies used, but also on the nature of the services customers require. It makes a difference, for example, whether we create a tunnel using the drill and blast method or a tunnel boring machine.

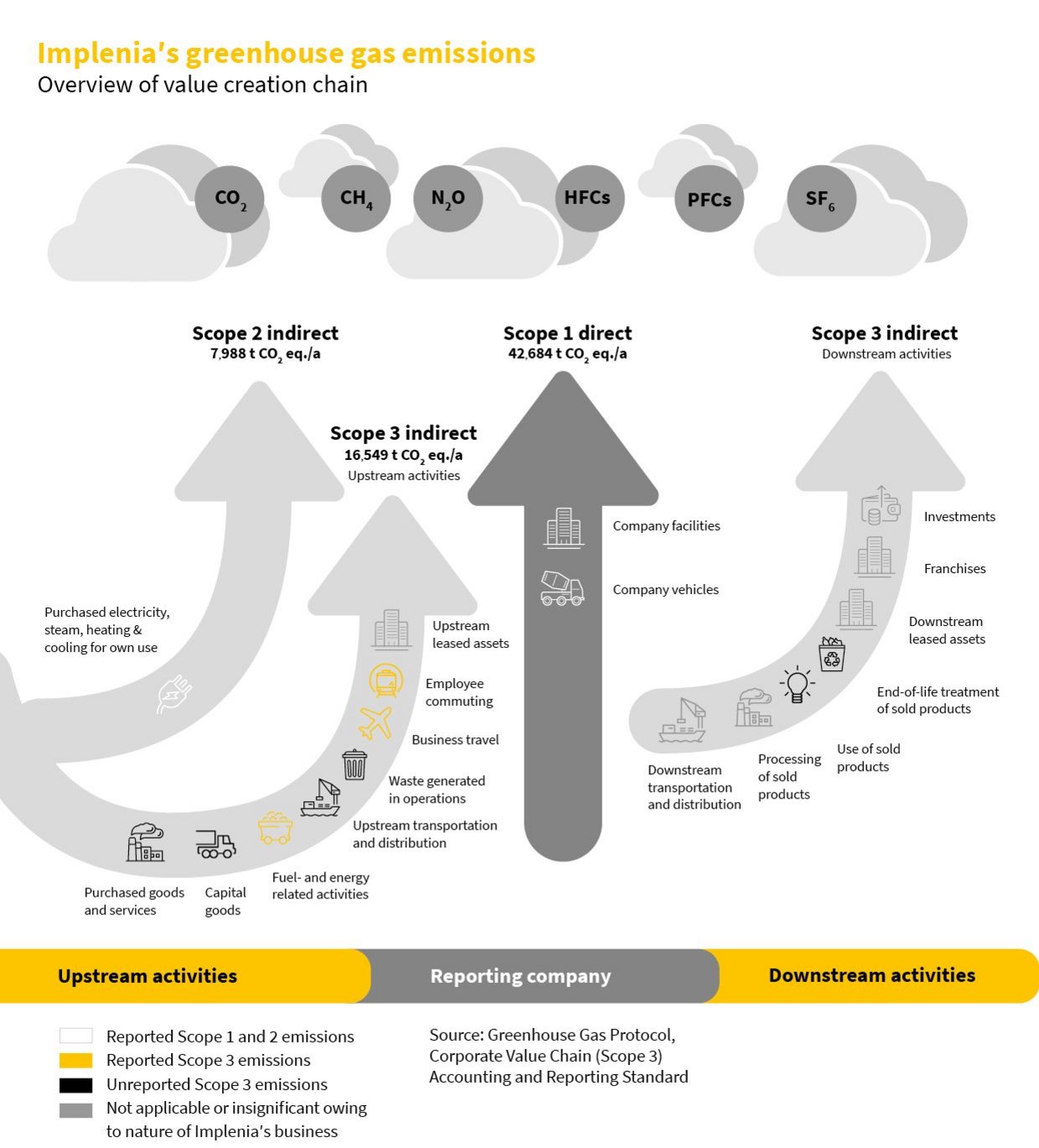

Greenhouse Gas Protocol

| Category | Definition |

|---|---|

Scope 1 | Emissions caused directly by a company’s use of fuel in operations and transport, as well as fugitive emissions. |

Scope 2 | Indirectly generated emissions resulting from the use of purchased electricity, steam, heating and cooling. |

Scope 3 | All other indirect emissions in a company’s value chain caused by its activities. |

Implenia is publishing its carbon footprint since 2012. In 2020, Implenia calculated its Group-wide CO2 footprint for the first time using a new, more comprehensive method. In Switzerland, Germany, Norway, Sweden, Austria (including Romania) and France, the Group emitted 16.7 tonnes of CO2 equivalents per million Swiss francs of revenue. This figure serves as the benchmark for the reduction trajectory up to 2025.

In terms of absolute CO2 emissions, those in Switzerland are almost twice as high, at 56% of the Group total, as in Germany, which accounts for 33%. The remaining 11% of emissions is generated in the markets of Norway, Sweden, Austria (including Romania until mid-2022) and France.

In line with the Paris Climate Agreement, Implenia wants to help limit the warming of the Earth’s atmosphere to 1.5 degrees. The company goal, therefore, is not to generate any net emissions under any Scope by 2050 at the latest.

Scope 1 & 2 emissions

Implenia calculates its CO2 footprint each year and uses this data as a benchmark to reduce both greenhouse gas emissions and primary energy consumption. Between 2012 and 2019, for example, the company managed to reduce its Scope 1 & 2 CO2 emissions in Switzerland by almost 15%.

In order to meet climate targets set by the UN and the countries in which Implenia operates, Implenia has tightened its CO2 targets for 2025 several times. For example, the company now wants to reduce its Scope 1 and 2 revenue-adjusted emissions by 3% per year across the Group. This represents a 15% decrease over the entire period compared to 2020.

Most of Implenia’s Scope 1 and 2 greenhouse gas emissions are caused by its construction sites and production facilities. Around 65% of these emissions are the result of burning diesel.

Implenia’s greenhouse gas emission figures include direct emissions from the operation of our own construction machinery, trucks, production facilities and yards (“Scope 1” as defined by the international Greenhouse Gas Protocol), as well as indirect greenhouse gas emissions from grid energy like electricity and district heat (Scope 2).

In absolute terms, Implenia was able to reduce its carbon footprint once again, from 62,981 tonnes of CO2 equivalent in the base year 2020 to 50,672 tonnes of CO2 equivalent in 2022. Adjusted for turnover, this represents a reduction of around 10.5%.

Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in tonnes of CO2-eq

Including recalculation of 2020-2023

Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in % by energy source for the year 2024

Revenue-adjusted greenhouse gas emissions, Implenia Global (Scopes 1+2)

in tonnes of CO2-eq / Mio. CHF

Including recalculation of 2020-2023

Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in % by usage for the year 2024

Due to the smaller number of construction projects and depending on the construction phase or choice of energy sources, CO2 emissions can fluctuate in the smaller markets of Austria, Sweden and France.

Scope 3 emissions

Initial figures do not include all the other indirect emissions generated in up- and downstream processes (Scope 3). In particular, the extraction, manufacturing for production and transportation of construction materials and the subsequent use of buildings and structures cause significant emissions, which obviously affect a construction project’s overall impact. These emissions can be many times larger than those recorded under Scope 1 and 2. Although Implenia’s influence over these processes is generally low and although it is difficult to gather the relevant information, the company is seeking to expand its database in this area as well.

Implenia has identified the major contributors to the company's total CO2 footprint over the value chain. For this, the relevance of the 15 Scope 3 categories to the company’s activities were evaluated based on the GHG protocol, available internal and external databases and construction industry benchmarks. The following categories have high priority for the Implenia:

- Category 1: Purchased goods and services

- Category 2: Capital goods

- Category 3: Fuel & energy related activities

- Category 4: Upstream transportation and distribution

- Category 5: Waste generated in operations

- Category 6: Business travel

- Category 7: Employee commuting

- Category 11: Use of sold products

- Category 12: End-of-life treatment of sold products

Reporting in these categories will be continuously expanded in the coming years. In particular, the categories "Purchased goods and services" and "Use of sold products" are highly relevant in the construction industry and account for a large share of Scope 3 emissions. For 2022, the following categories are reported at Group level: "Fuel and energy-related activities", "Business travel" and "Employee commuting".

Greenhouse gas emissions, Implenia Global (scope 3)

in tonnes of CO2-eq by category

Calculated Scope 3 emissions. Category 1 including concrete and steel. Further relevant categories will follow.

CO2 compensation

Since 2014 Implenia Switzerland is compensating the CO2 emissions of its flights. For the upcoming year, it is the ambition of Implenia to define a groupwide agreed strategy for CO2-compensation.

Currently Implenia Switzerland works with the myclimate Foundation to offset greenhouse gases released as a result of its business air travel. The projects that the offset contributions help fund in Central and South America meet the highest standards. For example, in 2022 Implenia Switzerland offset flight emissions of around 100 tonnes by funding a municipal reforestation project run to standards set by the Plan Vivo Foundation. This project in Nicaragua removes around 600,000 tons of CO2 from the atmosphere every year.

Energy consumption

In 2022, the Implenia Group consumed around 258 gigawatt hours of energy. The company’s biggest energy source by far (final energy) is the diesel it uses as fuel for machinery, commercial vehicles and cars. Next come fuels that are used mainly for generating process heat in its surfacing works, such as natural gas and heating oil.

Energy usage, Implenia Global (Scope 1+2)

in MWh by energy source

Including recalculation of 2020-2023

Electricity consumption

Implenia optimises its energy consumption wherever it can and prioritises clean energy sources. Since 2014, Implenia Switzerland has purchased certificates of origin for hydroelectric power for around 10,000 megawatt hours every year. These have come exclusively from domestic sources since 2020.

Implenia Germany buys certificates of origin for hydropower for all its construction sites and office locations. Implenia Sweden covers all its construction projects in the same way. And Implenia Norway has purchased certificates for first projects as well.

In total, around 55% of electricity consumed by Implenia comes from renewable sources or is covered by certificates of origin.

Since 2022, Implenia has been reporting Scope 2 emissions not only using the "location-based "1 method but also the "market-based "2 method in accordance with the Greenhouse Gas Protocol.

1 Location-based figures calculated with country-specific emission factors from the International Energy Agency (IEA)

2 Market-based figures with inclusion of guarantees of origin and emission factors of electricity suppliers where available

Greenhouse gas emissions electricity, Implenia Global

market-based versus location-based for the year 2024 in tonnes of CO2-eq

Electricity usage, Implenia Global

in % renewable energy for the year 2024

A well as predominantly using clean electricity, Implenia also harnesses its buildings to generate its own electricity. Solar systems on the roofs of its Swiss yards near Satigny (GE), Vétroz (VS) and Schattdorf (UR) and at the Ecublens asphalt plant (VD), for example, have been supplying solar power for years. The 2,500 square metres of photovoltaic modules on the roof of the Ecublens plant produce almost half a gigawatt hour of electricity per year.

In Germany, a photovoltaic system on the roofs of Implenia’s subsidiary BBV Systems GmbH in Bobenheim-Roxheim (RP) produces more than 400 megawatt hours of electricity per year. Almost half the energy generated is consumed on site. In total, the company’s own solar systems generate more than 1.3 gigawatt hours of green electricity per year. The target for 2025 is to generate three gigawatt hours of solar power a year.

PV electricity generated, Implenia Global

in kWh

Energy monitoring at our yards

Implenia operates 24 major yards throughout Europe. They function primarily as repair and maintenance centres and material storage depots. But many of these sites also have office premises. Running these complexes, which can be very large, requires a lot of heat and electricity.

To find out more about energy-saving potential at its yards, Implenia has put eight of them under the microscope in recent years. Measurements were carried out by Tetrag Automation AG, which uses the “e3m” energy monitoring solution for accurate high-resolution analysis of consumption data.

Its analysis showed that the greatest optimisation potential is during downtimes – at night and over the weekend when no work is being done. The experts at Tetrag identified a whole series of other efficiency measures, including the use of modern lighting and heating technology.

In response to this analysis, Implenia has taken various measures to improve energy efficiency. In 2022, for example, the Satigny yard replaced all the fluorescent tubes in its offices and workshops with LED lights.

Circular economy

Every year the Global Footprint Network announces “Earth Overshoot Day”: the day on which humanity uses up all the natural resources that the earth can regenerate that year. In recent years this has always arrived in July, demonstrating how humanity is completely overstraining our planet’s capacities.

To become sustainable over the long term, the economy as a whole has to move away from linear production chains and start thinking in cycles. In concrete terms, products should not be destroyed or deposited in landfills after use. Instead, the materials contained in these products should wherever possible be recovered, reprocessed and returned to the production cycle as secondary raw materials.

By 2025 Implenia aims to develop circular business models and use innovative methods to close its material cycles. It is important not just to recycle worn-out products, but also to actually use the secondary raw materials that recycling produces. Wherever possible, therefore, Implenia uses at least 50% recycled concrete for its own development projects, made in a concrete works situated close to the construction site.

Gravel that Implenia excavates from building pits is – if conditions permit – immediately processed on site and used to make concrete or to backfill within the same project. This avoids waste and saves on transport. It is a particularly effective approach in tunnelling, where Implenia can use the rock it excavates to make concrete locally (Closing material cycles on site).

In order to close cycles, it is important in the long term not just to optimise the recycling process, but also to optimise product design. New products have to be manufactured in such a way that the component materials can later be separated out and sorted without excessive use of mechanical processes, energy or chemicals. In the construction industry, the use of dry joints, for example, makes it easier to separate and reuse individual elements subsequently. Once a component has reached the end of its life, the individual material layers can be separated from each other and returned to the cycle as secondary raw materials.

Division Real Estate is increasingly following this approach under the guidance of its new Real Estate Products unit (REP). REP looks for flexible, cost-efficient and environmentally friendly solutions using standardised real estate products. Construction methods based on prefabricated elements are combined with circular economy approaches.

The aim is to improve both the quality and sustainability of the buildings compared to traditional construction methods, to shorten delivery times and to reduce cost uncertainties. Planners use a configurator to combine prefabricated elements and modules flexibly to meet customer needs.

The Real Estate Products business unit has defined its own circular strategy along with a set of circular principles. These are being integrated systematically in the development and production of three products: Green Hospitality, Subsidised Housing and “Best Age”. In both 2021 and 2022, REP subjected itself to external assessment by Circular Globe to measure its own progress on circular economy matters. Implenia recently became the first company in the property sector to achieve the “Advanced” maturity level.

Grey energy of building materials

The term “grey energy”, also known as “embodied energy”, refers to the amount of energy needed to make a product – whether this is a building material, a building element, or even an entire building. All the relevant steps are included: from raw material extraction and transport, through production and processing, to installation or use on the construction site.

Under the calculation method used by Implenia, based on Swiss standard SIA 2032, refurbishment during the operation of a building and all the work required at the end of its life also count towards that building’s grey energy profile. According to this definition, renewable energies are not counted in the total.

Grey energy – and the related grey carbon dioxide emissions – play a key part when considering a building’s sustainability. For new and well-insulated buildings, energy consumption and CO2 emissions from materials and construction during the building phase can be three times higher than generated over the entire operating phase.

Optimised design and implementation can significantly reduce a building’s embodied grey energy consumption and emissions. In many cases, this also leads to a reduction in construction costs.

At all stages of its construction projects, therefore, Implenia seeks to use all the available levers to reduce the grey energy and CO2 content. This starts with strategic planning.

A compact building with a smaller exterior area tends to perform better in terms of material consumption. The scale of the foundations, retaining measures and subterranean structures also has an influence. During the construction phase, grey energy consumption can be further reduced by the choice of construction method (solid wall or lightweight), the design of the supporting structure and the type of building technology used.

Various widely-used standards and assessment systems for sustainable construction include grey energy in their measurements. More and more government authorities are also asking for details of grey energy use. In Switzerland, Geneva and other cantons are introducing grey energy and carbon calculations as a part of the planning permission process.

Similarly, several European countries have introduced threshold values for CO2 in new residential buildings. France, for example, has defined a reduction path that will allow 560 kilograms of CO2 per square metre of living space from 2024, 320 kilograms from 2027 and only 260 kilograms from 2028.

In line with these trends, Implenia has been using the SIA energy efficiency path to evaluate all its development projects in Switzerland since 2021 (see also: Developing our own projects). This defines methods and target values for recording primary energy consumption and CO2 emissions during the construction and operation of a building, as well as also those caused by the associated mobility.

Water consumption

Building sites don’t just use solid materials like concrete, wood and composites. Water is an equally important basic material for building. It is used in great quantities for drilling, for mixing concrete, mortar and plaster, for cleaning and humidification of building elements and processes, as well as for sanitary facilities.

Summer water shortages have become a real challenge in Implenia’s work. Saving water is an increasingly important issue in the construction industry. Implenia does various things to reduce its water consumption. One of these is to use meticulous water treatment processes and another is to reuse wastewater directly on site.

In Sweden and France, Implenia has been measuring water consumption on all construction sites for several years. As well as showing consumption values, the measuring system also indicates where and how water could be saved. Comprehensive data is not yet available from other countries, but the company is currently extending the recording of water consumption to its other markets.

Waste and hazardous substances

The construction industry accounts for around half of all the waste generated in Europe. Much of Implenia’s environmental impact is also due to waste. Most of this is created when buildings and structures are demolished, though considerable amounts of waste are also generated when building new structures.

Implenia optimises the quantity of waste it produces through improved processes and good planning, and to use components and processes that allow materials to be separated easily and recycled at the end of their lifetimes (see also: Circular Economy).

Implenia practises systematic waste management on its sites; it makes considerable efforts to dispose of construction waste by type and to promote recycling. For example, in Switzerland it uses separate containers for different waste materials, such as concrete, metal, wood and plaster.

This means that subcontractors can separate waste directly on site and achieve recycling rates of up to 90%. Implenia is well on track to achieve its target for 2025, which is to increase the recycling rate to 100% for materials that can be sensibly recycled.

The company takes special care with hazardous materials on its sites, such as diesel, petrol, bitumen, gas cylinders, lithium batteries and spray cans. To protect people and the environment, Implenia regularly trains its construction site personnel on how to store and transport hazardous materials. Since 2020, all the key documents on handling hazardous substances have been stored centrally on the Intranet.

On-site environmental management

Environmental standard and environmental concept

GRI 2-23, 2-24

An internal environmental standard has been applied across all areas of Implenia’s business since 2017. This includes Group-wide minimum requirements for waste disposal, soil protection, water treatment, noise reduction, clean air and energy consumption. These requirements – summarised on an information sheet for ease of use – must be followed by project teams on all construction sites.

In addition to its general environmental standards, Implenia applies project-specific environmental concepts to its building construction and infrastructure projects. These concepts govern the way construction sites are organised and include comprehensive sustainability criteria. Project managers are given a module-based handbook to work with, which gives them background information to help assess environmental risks correctly and take precautionary action early.

Checklists help project teams reduce energy consumption and noise pollution, optimise waste management and reduce impacts on air, soil and water. This makes it easier to comply with legal requirements, but also to meet additional criteria set by clients or necessitated by the desire to achieve a particular sustainability certification.

Smart construction logistics

Only about 30% of working time on construction sites leads directly to value creation. The remaining 70% is indirectly productive and spent on things like distribution or preparation: e.g. time spent on locating materials, maintenance, transportation, disposal and troubleshooting.

Well-organised construction logistics can significantly improve value creation and sustainability on a construction site. Implenia’s subsidiary Building Construction Logistics GmbH (BCL) specialises in precisely this field. It optimises logistics processes in order to minimise wastes of time and resources, as well as to reduce costs and the risk of missing deadlines.

Good construction logistics also cuts waste and emissions of dust, noise and air pollutants – by eliminating unnecessary transport, for instance, or increasing the amount of recycling. A good example of this is the Telli construction site in Aarau (CH), where BCL uses a tailor-made logistics concept to reduce mixed construction waste by 70%.

Sensitising employees

GRI 2-23, 2-24

Implenia regularly informs and educates employees about environmental issues, knowing that this has a positive influence on energy and resource consumption. Three awareness-raising campaigns are carried out each year on construction sites in Switzerland, addressing key environmental issues such as soil protection, water purification, air pollution, noise reduction, waste disposal and CO2 emissions.

Awareness campaigns use different communication channels at different levels: site personnel receive a quarter-hour training session, and a multilingual information poster is hung up in highly visible places on the construction site for several weeks. Project managers receive additional training and in-depth documentation.

Reporting of environmental incidents

Implenia has been recording incidents on construction sites for many years, with a particular focus on accidents involving people. In 2020, the Group introduced a standardised system for all countries and divisions to investigate all types of incident in a structured manner. Environmental incidents are recorded separately in this system and classified into categories. In line with the Group’s 2025 sustainability goals, the system is currently being established in all countries and divisions.

A lot can happen on a construction site. For example, diesel or hydraulic oil could accidentally enter the ground or water, nearby roads could be polluted, or a protected tree could be damaged. To identify the cause of such incidents and learn from mistakes, the responsible managers (usually assisted by safety officers) carry out a “root-cause analysis”. Any measures that are needed can then be taken and their effectiveness monitored.

Mobility

Implenia uses hundreds of vehicles every day. Across the Group, its cars, trucks and vans, but also excavators, rollers and other specialised vehicles and machinery consume a total of approximately 13 million litres of fuel a year.

When procuring vehicles and machinery, Implenia prioritises low-emission options. In Switzerland and Germany, internal vehicle and leasing regulations encourage the use of electric cars. In Sweden, France, Austria and Norway, in has small fleets of electric delivery and passenger vehicles. Many offices provide their employees with e-bikes.

Technology has now progressed to the point where alternatives to the traditional internal combustion engine are available on the market not just for cars but also for heavy construction machinery. For example, Implenia operates several hybrid excavators in Switzerland. In Norway the company has gone a step further and has completed its first projects using purely electric-powered construction site vehicles. And for its underground railway construction site in Stockholm, Implenia Sweden, together with Finnish manufacturer Sandvik, has developed a dumper fuelled by fully biodegradable hydraulic oil. The use of biodiesel to drive construction machinery is steadily increasing.

Implenia uses incentives and awareness campaigns to encourage employees to use public transport for business travel. Employees who regularly travel by train to appointments or who do not use a company car can apply for discount cards and rail passes. Employees at head office receive a monthly mobility bonus in addition to their salary, which they can use to travel by public transport.

Green offices

The biggest levers with which Implenia can control its environmental impact are to be found on our construction sites. However, environmentally friendly approaches in our office buildings can also make a difference. In 2020, therefore, Implenia launched its “Sustainable Office” initiative, which applies various measures in our countries and divisions relating to mobility, waste and materials.

The initiative includes employee awareness campaigns, analysis and proposals for improvements at specific locations, and various pilot projects. Implenia’s basic principle here is that even small measures can have a positive effect. And that sustainable habits can lead to sustainable thinking in other areas too.