Respect for the environment

Content

Environmental management

GRI 102-7

Implenia operates an ISO 14001-certified environmental management system. By the end of 2021, 88% of its corporate units had gained the required certification. Each division has several HSEQ officers (HSEQ = Health, Safety, Environment, Quality). With expert support from the Sustainability Department, these officers are responsible for implementing environmental measures on construction sites, reporting environmental incidents, increasing energy efficiency and optimising the use of resources – by promoting recycling, for example. Over the years, Implenia has significantly improved environmental management on its construction sites. Our aim for 2025 is to further intensify our efforts to ensure professional environmental management for all our projects, and to prevent environmental incidents.

In Switzerland, Implenia systematically collects data on production facilities, depots, office premises, building sites and development projects, as well as on transportation and paper consumption. It records the main energy and material flows, from initial extraction of raw materials to the finished structure.

A web-based software package allows the company to capture HSEQ data continuously from various sources and show it in real time, as well as to generate specific analyses to help monitor outcomes. The data is currently only available at country level, but Implenia is working constantly to improve its availability, up-to-dateness and regional granularity.

Energy and climate

CO2 emissions in Switzerland

GRI 302-1, 305-1, 305-2, 305-4, 305-5

In Switzerland, almost 90% of Implenia’s total greenhouse gas emissions come from construction sites, yards and surfacing works. Around two-thirds of these emissions result from burning fuels such as diesel and gasoline. Only a third comes from oil and gas-fired heat generation.

In 2013 Implenia set itself the goal of reducing both its greenhouse gas emissions and its primary energy consumption in Switzerland by 2.5% a year relative to revenue by 2020. The target for the first six years until the end of 2019 was, therefore, 15%. Thanks to numerous measures (see below), the company very nearly achieved this ambitious goal. Its absolute CO2 emissions fell over the period by 15.1%. In relation to revenue, the reduction was 12.8%.

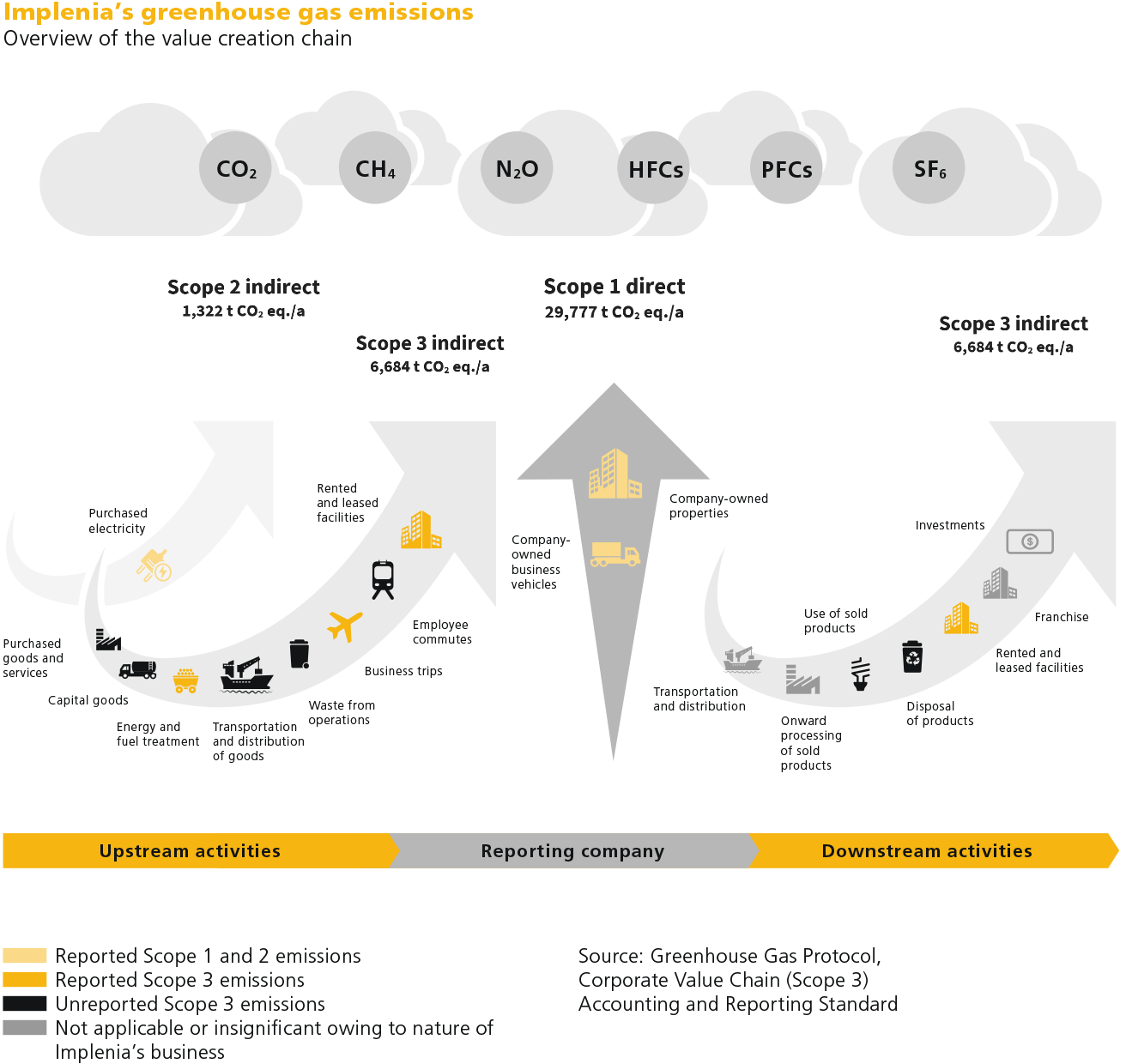

Implenia’s greenhouse gas emission figures include direct emissions from the operation of our own construction machinery, trucks, production facilities and depots in Switzerland (“Scope 1” as defined by international rules on greenhouse gas calculations), as well as indirect greenhouse gas emissions from net-bound energy like electricity (Scope 2).

The figures only partially include all the other indirect emissions generated in upstream or downstream processes (Scope 3). Significant indirect emissions are created by the production of construction materials and usage of the structures we build. These emissions can be many times as large as those recorded under Scope 1 and 2. However, Implenia usually has very little influence on these processes, and it is often hard to access the relevant data.

The company’s CO2 emissions can vary significantly from year to year, because they do not depend solely on the amount of work done or on the technologies used, but also on the nature of the services customers require. It makes a difference, for example, whether we create a tunnel using the drill and blast method or a tunnel boring machine.

Implenia has worked with the myclimate Foundation since 2014 to offset greenhouse gases released as a result of its business air travel. As well as reducing CO2 emissions, one of the projects in South America funded by the offset payments in the last years improves public health and reduces pressure on local forests: in six different regions of Bolivia and Paraguay inefficient wood ovens have been replaced by solar ovens or more efficient cookers. The deployment of 50,000 environmentally friendly cookers will reduce CO2 equivalents by around half a million tonnes over seven years.

In summer 2022, we recalculated our 2020 footprint with an updated methodology to set as a base year for our 2025 goals. The new methodology was also applied to the 2021 calculation, but not to historic data before the new 2020 base year.

The base year 2020 footprint now includes all our home markets and energy sources, and following emission factors have been used consistently: Scope 1 = Defra, Scope 2 = IEA (electricity) & GaBi (district heating). This resulted in overall higher emission values than calculated with the old methodology, where some locations and energy sources were still missing.

Base year 2020: Greenhouse gas emissions, Implenia Switzerland (Scopes 1 + 2)

by energy source in tonnes of CO2 equivalent

Base year 2020: Greenhouse gas emissions, Implenia Switzerland (Scopes 1 + 2)

by usage in %

Old method: Greenhouse gas emissions, Implenia Switzerland (Scopes 1+2)

by fuel type in tonnes of CO2 equivalent

Old methodology: Greenhouse gas emissions, Implenia Schweiz (Scopes 1+2)

by usage in tonnes of CO2 equivalents & %

Old methodology: Revenue-adjusted greenhouse gas emissions, Implenia Switzerland (Scopes 1+2)

in tCO2/Mio. CHF and in % of the base year

Greenhouse gas emissions from electricity consumption, Implenia Switzerland

by type and in tonnes of CO2 equivalent

Greenhouse gas emissions from air travel, Implenia Switzerland

in tonnes of CO2 equivalents

*Update August 2022: Missing flight data from 2019 - 2021 added and compensated

Greenhouse gas emissions, Implenia Switzerland (Scope 3)

emissions from energy and fuel treatment, business trips and rented/leased facilites in tonnes of CO2equivalent

Greenhouse Gas Protocol

| Category | Definition |

|---|---|

Scope 1 | All direct greenhouse gas emissions |

Scope 2 | Indirect greenhouse gas emissions based on purchased electricity or heat |

Scope 3 | Other indirect emissions, such as those from extraction and production of purchased materials and fuels, transport by vehicles not operated by the reporting company, business trips etc. |

The group’s carbon footprint

Implenia has recently analysed its carbon footprint in detail, improved its data collection and extended this across all the Group’s home markets. Implenia has tightened its CO2 targets for 2025 again in order to align with UN climate goals and Switzerland’s own national climate objectives. The company’s aim now is to reduce Group-wide revenue-adjusted emissions by 3% a year. This implies a total reduction across the whole time span of 15% compared with today.

Implenia’s Group-wide carbon footprint, calculated for the first time for 2019, covers the home markets of Switzerland, Germany, Norway, Sweden and Austria / Romania. Overall, the Group generated 56,545 tons of CO2-equivalent emissions in these countries in 2020. Emissions in Switzerland accounted for 55% of the total and were roughly twice as high as those in Germany, which accounted for 28%. The remaining 17% was emitted by Implenia divisions in Norway, Sweden and Austria / Romania. Implenia has undertaken to calculate and verify its footprint more accurately, as well as to understand it better and define country-specific CO2 reduction paths.

In summer 2022, we recalculated our 2020 footprint with an updated methodology to set as a base year for our 2025 goals. The new methodology was also applied to the 2021 calculation, but not to historic data before the new 2020 base year.

The 2020 base year footprint now includes all our home markets and energy sources, and following emission factors have been used consistently: Scope 1 = Defra, Scope 2 = IEA (electricity) & GaBi (district heating). This resulted in overall higher emission values than calculated with the old methodology, where France as well as some other locations and energy sources were still missing.

Base year 2020: Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in tonnes of CO2 equivalents

Base year 2020: Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

by energy source and in %

Base year 2020: Revenue-adjusted greenhouse gas emissions, Implenia Global (Scopes 1+2)

in tCO2/Mio. CHF

Old methodology: Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

in tonnes of CO2 equivalents

Old methodology: Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

by fuel type in %

Old methodology: Revenue-adjusted greenhouse gas emissions, Implenia Global (Scopes 1+2)

in tCO2/Mio. CHF

Old methodology: Greenhouse gas emissions, Implenia Global (Scopes 1 + 2)

by country in tonnes of CO2 equivalents & %

Energy consumption in Switzerland

Implenia consumed around 142 gigawatt hours of energy in Switzerland in 2020. Since the base year of 2012/13, total energy consumption in relation to revenue has fallen by 17 percent. The company’s biggest energy source by far (final energy) is the diesel it uses as fuel for machinery, commercial vehicles and cars. Next come fuels such as natural gas and heating oil that are used mainly for process heat in its surfacing works.

Implenia optimises its energy consumption wherever it can and prioritises clean energy sources. Since 2014, it uses certified electricity from hydro power to meet its electricity needs at Swiss sites: Implenia offsets electricity consumption from fossil fuel generation by purchasing renewable energy guarantee of origin certificates. Since 2020, these have come from domestic sources only. The plan for Germany, Sweden and Norway is to offset with guarantee of origin certificates from European hydropower in the foreseeable future.

For many years now, Implenia has produced its own solar power on the roofs of its yards in Satigny (GE), Vétroz (VS) and Echandens (VD), as well as at the gravel plant at Claie-aux-Moines near Savigny (VD) and the surfacing works in Ecublens (VD). The 2,500 square meters of photovoltaic modules on the roof of the Ecublens plant, for example, produce almost half a gigawatt hour of electricity per year, equivalent to 85 percent of the entire industrial plant’s consumption. A quarter of the solar power generated is used directly on site, while the rest is fed into the local power grid.

Two additional roof-based photovoltaic systems were connected to the grid in 2020 and 2021: at the Schattdorf (UR) yard and on the buildings of subsidiary BBV Systems GmbH in Bobenheim-Roxheim (DE).

Altogether, Implenia’s own solar power systems produce more than one gigawatt hour of electricity a year. This is equivalent to approximately 4% of the company’s electricity needs in Switzerland. In 2018 the company set itself the goal of doubling its own production of electric power by 2020, the first step being to install photovoltaic systems on the roofs of its yards in Germany. The objective was not met, but Implenia continues to work on this strategy and has set a new target figure for 2025, which applies to all home markets. Building facades will also be used for solar power systems. The target is to generate three gigawatt hours of solar power a year.

Energy consumption, Implenia Switzerland

by fuel in %

PV electricity generated, Implenia Switzerland

in kWh

*Data for 2020 estimated for Vétroz & Satigny

Grey energy of building materials

The term “grey energy”, also known as “embodied energy”, refers to the amount of energy used to make a product – whether this is a building material, a building element, or even an entire building. It includes all the steps involved from the extraction of raw materials to production and processing, right through to transportation and installation.

Grey energy plays a key role when assessing sustainability. In the case of new buildings, it is often greater than the operational energy used across the whole life-cycle of the building. Targeted planning and implementation can reduce the grey energy consumed by a building by up to 30%. In many cases, this also leads to a reduction in construction costs.

At all stages of its construction projects, Implenia seeks to use the available levers to reduce grey energy. This already starts at the strategic planning stage where, for example, compact buildings with a minimal outer surface tend to do better in terms of material inputs. The scale of the foundations, construction pit supports and subterranean structures also has an influence. During the construction phase, grey energy levels can be further reduced by the choice of construction method (solid wall or lightweight), the design of the supporting structure and the type of building technology used.

Various standards and assessment systems for sustainable construction include grey energy measures. These include Minergie ECO, the Swiss Sustainable Construction Standard (SNBS), “2000-Watt Site” certification and the DGNB certificate issued by the Swiss Sustainable Building Council (SGNI).

Regardless of all these certificates and labels, Implenia’s aim from 2021 is to apply the SIA Energy Efficiency Pathway to all of its self-developed projects. This sets standards for primary energy consumption and CO2 emissions generated by construction work, mobility and building operation. It includes the obligation to calculate and optimise grey energy in all projects.

Water consumption

Building sites don’t just use solid materials like concrete, wood and composites. Water is an equally important basic material for building. It is used in great quantities for drilling, for mixing concrete, mortar and plaster, for cleaning and humidification of building elements and processes, as well as for sanitary facilities.

Implenia’s markets are in countries where there is no lack of drinking water. Nevertheless, the company is committed to reducing its water consumption. This can be seen, for example, in its use of advanced water treatment processes and its reuse of wastewater directly on site.

In Switzerland and Sweden, Implenia systematically records how much water its construction sites and yards use. This new indicator does not just include consumption values, but also shows where and how water could be saved. The indicator is assessed every year so progress on water usage can be documented over time. The company plans to extended this targeted recording of water consumption to other country organisations.

Waste and hazardous substances

The construction industry accounts for around half of all the waste generated in Europe. Much of Implenia’s environmental impact is also due to the waste it creates. Most of it is created when buildings and structures are demolished, though substantial volumes are also generated during construction itself.

Implenia tries through good planning to reduce the quantity of waste it produces, and to use components and processes that allow materials to be separated easily and recycled at the end of their lifetimes (see Circular Economy chapter).

Implenia practises systematic waste management on its sites, and makes a considerable effort to dispose of construction waste by type and to encourage recycling. For example, it sets up different containers for different waste materials, such as concrete, metal, wood and plaster. This means that subcontractors can separate waste directly on site and achieve recycling rates of up to 90%. Implenia’s goal for 2025 is to raise the recycling rate to 100% for materials that can be sensibly recycled.

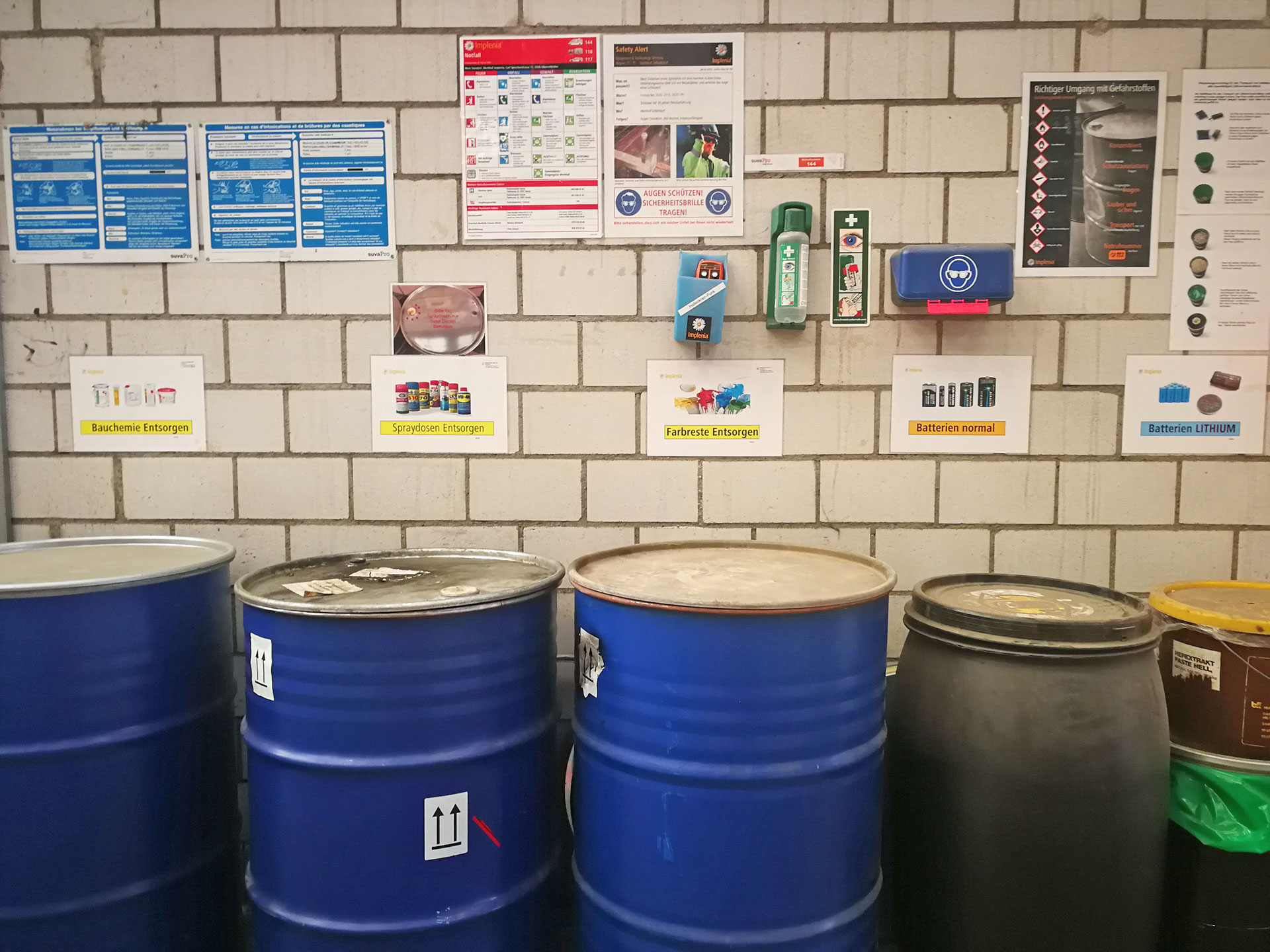

It takes special care with hazardous materials on its sites, such as diesel, petrol, bitumen, gas cylinders, lithium batteries and spray cans. To protect people and the environment, Implenia regularly trains its construction personnel how to store and transport hazardous materials. Since 2020, all the relevant documents about handling hazardous substances have been stored centrally on the intranet.

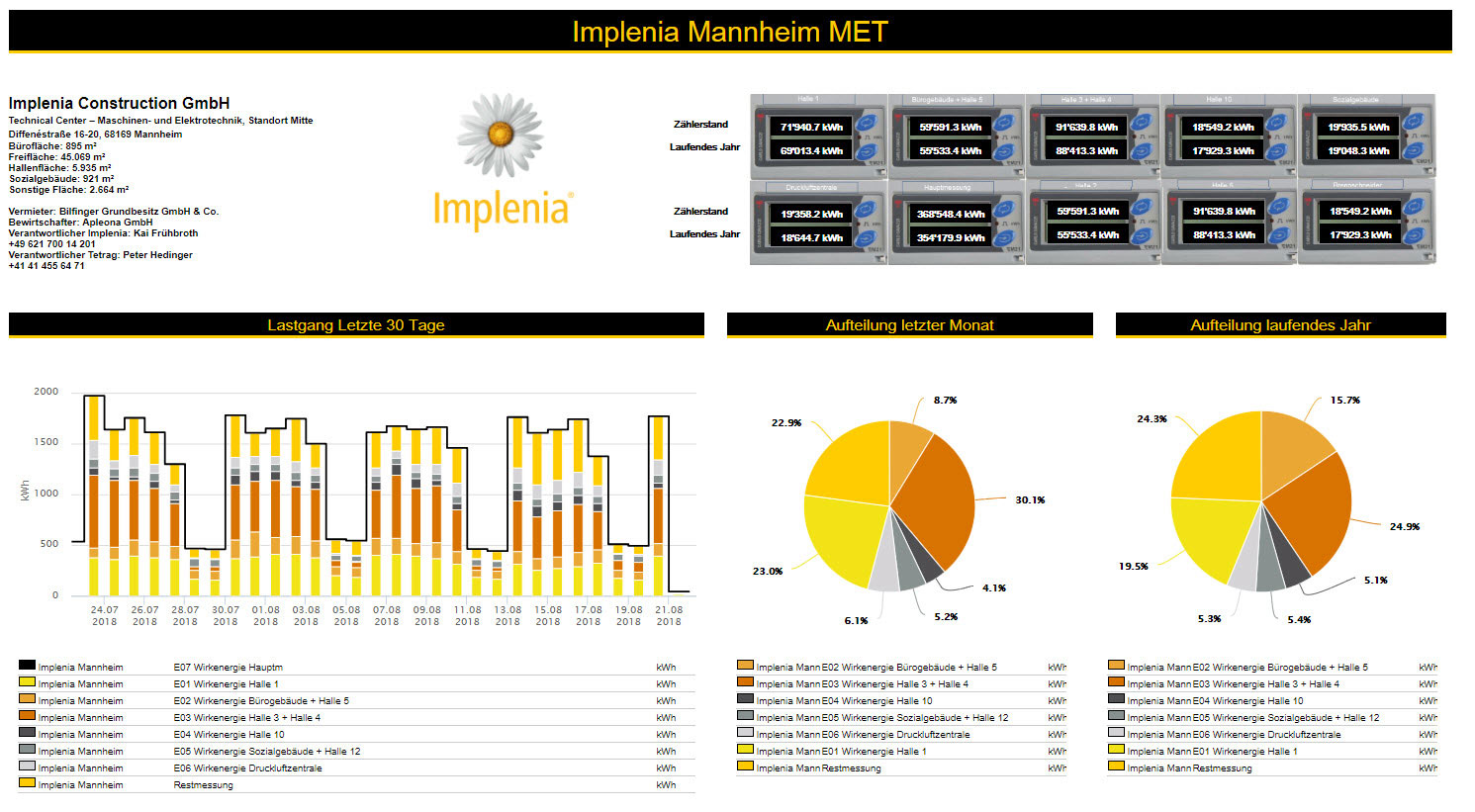

Energy monitoring at our yards

Implenia runs 30 or so large yards across Europe. They function primarily as repair and maintenance centres and material storage depots. But many of these sites also have office premises. Running these complexes, which can be very large, requires a lot of heat and electricity.

To find out more about energy-saving potential at its yards, Implenia launched a pilot project at the end of 2017 that put eight of them under the microscope. Measurements were carried out by Tetrag Automation AG, the company uses the “e3m” energy monitoring solution that it developed itself and which is perfect for high-resolution analysis of consumption data.

Its analysis showed that the greatest optimisation potential is during downtimes – at night and over the weekend when no work is being done. The experts at Tetrag identified a whole series of other efficiency measures, including the use of modern lighting and heating technology.

It was found that across all the yards analysed, there was potential to save around 100,000 kilowatt hours of electricity, the equivalent of roughly CHF 19,000 a year, so project costs will pay for themselves within a few years. The measures taken are an impressive example of how Tetrag’s solutions can combine financial and environmental benefits.

On-site environmental management

Environmental standard and environmental concept

GRI 102-11

An internal environmental standard has been applied across all areas of Implenia’s business since 2017. This includes Group-wide minimum requirements for waste disposal, soil protection, water treatment, noise reduction, clean air and energy consumption. These requirements – summarised on a double page for ease of use – must be followed by the project teams on all construction sites.

In addition to its general environmental standard, Implenia applies project-specific environmental concepts to its building construction and infrastructure projects. These govern the way construction sites are organised and include comprehensive sustainability requirements. Project managers are given a modular handbook to work with, which gives them background information to help them assess environmental risks correctly and take precautionary action early.

Checklists help project teams reduce noise pollution, optimise waste management and reduce impacts on air, soil and water. This makes it easier to comply with the legal requirements, but also to meet additional criteria set by the client or by the sustainability certification agencies.

Sustainability through construction logistics

The job of construction logistics is to support operational construction processes. Only about 30% of working time on construction sites is used productively to create value. The rest is devoted to distribution and set-up, i.e. things like locating items, maintenance, transportation and waste disposal work. Well-organised construction logistics can help improve value creation. Implenia’s subsidiary Building Construction Logistics GmbH (BCL) specialises in precisely this: minimising unnecessary wastes of time and resources, and reducing cost and deadline risks.

Many activities in addition to the actual building work cause problems for people and the environment – things like dust, noise, waste and airborne pollutants. This is where good construction logistics can help, reducing the transportation required to supply the site, for example, or cutting waste by significantly increasing recycling rates. At the “Tower 185” construction site in Frankfurt am Main, BCL ensured that 90% of residual materials were recycled.

BCL also coordinates the use of external personnel, such as security guards, monitors compliance with working conditions, such as rules on undeclared labour, and keeps things safe by, for example, collecting construction site waste promptly and thus reducing the volume of combustibles on site.

Sensitising employees

GRI 102-11

Implenia regularly informs and educates its employees about environmental issues, knowing that this has a positive influence on energy and resource consumption. Three awareness-raising campaigns are carried out each year on construction sites, addressing key environmental issues such as soil protection, water purification, noise reduction, waste disposal and CO2 emissions.

Awareness campaigns use different communication channels: site personnel receive a quarter-hour training session, and a multilingual information poster is hung up in highly visible places on the construction site for several weeks. Project managers receive additional training and in-depth documentation. Implenia is currently working on Group-wide reporting designed to ensure that all construction site personnel have participated in the relevant training.

Reporting of environmental incidents

Systematic logging of incidents, especially accidents to persons, has been a fixture at Implenia for many years. Since 2020, the Group has been creating a uniform system for all countries and divisions so that all types of incidents (accidents to persons, environmental incidents and near misses) can be investigated in a structured manner. A process has been defined that allows environmental incidents to be reported separately and allocated to categories. Over the years to come, this will help build up reliable incident statistics of the sort already kept by health and safety departments for accidents to persons, or that countries such as Sweden already have for environmental incidents.

A lot can happen on a construction site. If a tank springs a leak, for example, or a hydraulic hose bursts, oil can get into the ground and water. Dust and excavated earth can make the streets close to the construction site dirty, and protected trees can be accidentally damaged. To identify the cause of such incidents and learn from mistakes, the responsible managers (usually helped by safety officers) carry out a “root-cause analysis”. Any measures that are needed can then be taken and checked.

Sustainable mobility

Implenia uses hundreds of vehicles every day. Its cars, trucks and vans, but also excavators, rollers and other specialised vehicles and machinery consume a total of approximately 9.23 million litres of fuel a year in Switzerland.

This is why Implenia is careful to procure low-emission vehicles and machines. Its Vehicle Regulations specify that a passenger car in Switzerland should not emit more than 140 grams of CO2 per kilometre2. The company introduced a bonus/penalty system in Germany in 2020: employees who get a new company car can increase their vehicle configuration budget if they choose a model that comes below the current CO2 limit. If the vehicle is above this limit, the employee must accept a lower level of equipment or pay a supplement out of their own pocket.

Technology has now progressed to the point that alternatives to internal combustion engines are available not just for cars but also for heavy construction machinery. In Switzerland, for example, Implenia has purchased its first hybrid excavator. Implenia Norway has gone a step further and has already completed its first projects using purely electric construction site vehicles. Our Norwegian colleagues also have a small fleet of electric delivery and passenger vehicles.

Fortunately, mobility-related CO2 emissions have steadily declined over the years. This is partly due to the low fuel consumption of the leased fleet. Implenia uses incentives to encourage its employees to use public transport for business travel. All business train journeys can be charged against expenses, for example. Regular rail passengers and employees who waive their right to a company car can apply for discount passes and season tickets.

2 According to the new WLTP measurement method (the NEFZ method was used previously)

Substainable Office

The biggest levers with which Implenia can control its environmental impact are to be found on our construction sites. But environmentally-aware behaviour in our office locations can also achieve a lot when it comes to sustainability. Consequently, Implenia has launched its “Sustainable Office” initiative, which applies various measures in our countries and divisions relating to mobility, waste and materials.

These include employee awareness campaigns, analysis and proposals for improvements at specific locations, and various pilot projects. Implenia’s basic principle here is that even small measures can have a positive effect. And sustainable habits can lead to sustainable thinking in other areas too.

Awareness campaign

One awareness campaign in 2020 was designed to encourage employees across the whole Group to save energy in offices. An animated film clearly explains how it really doesn’t take much effort to adopt sustainable behaviour in the office. For example, by switching off all equipment in the evening, electricity that would otherwise be used for standby is saved, while turning room heating down a few degrees can save a large amount of heat energy.

Paper consumption

The environmental impact of paper consumption is comparatively low in construction companies. However, paper usage has a symbolic status in an office environment, so Implenia measures this too. It is pleasing to note that overall paper consumption at the company has trended downwards in recent years, and the proportion of environmentally certified paper has risen to almost 100%.

Paper consumption, Implenia Switzerland

in kg