Secondo tubo San Gottardo - Lot 241, Main Tunnel North

Short description

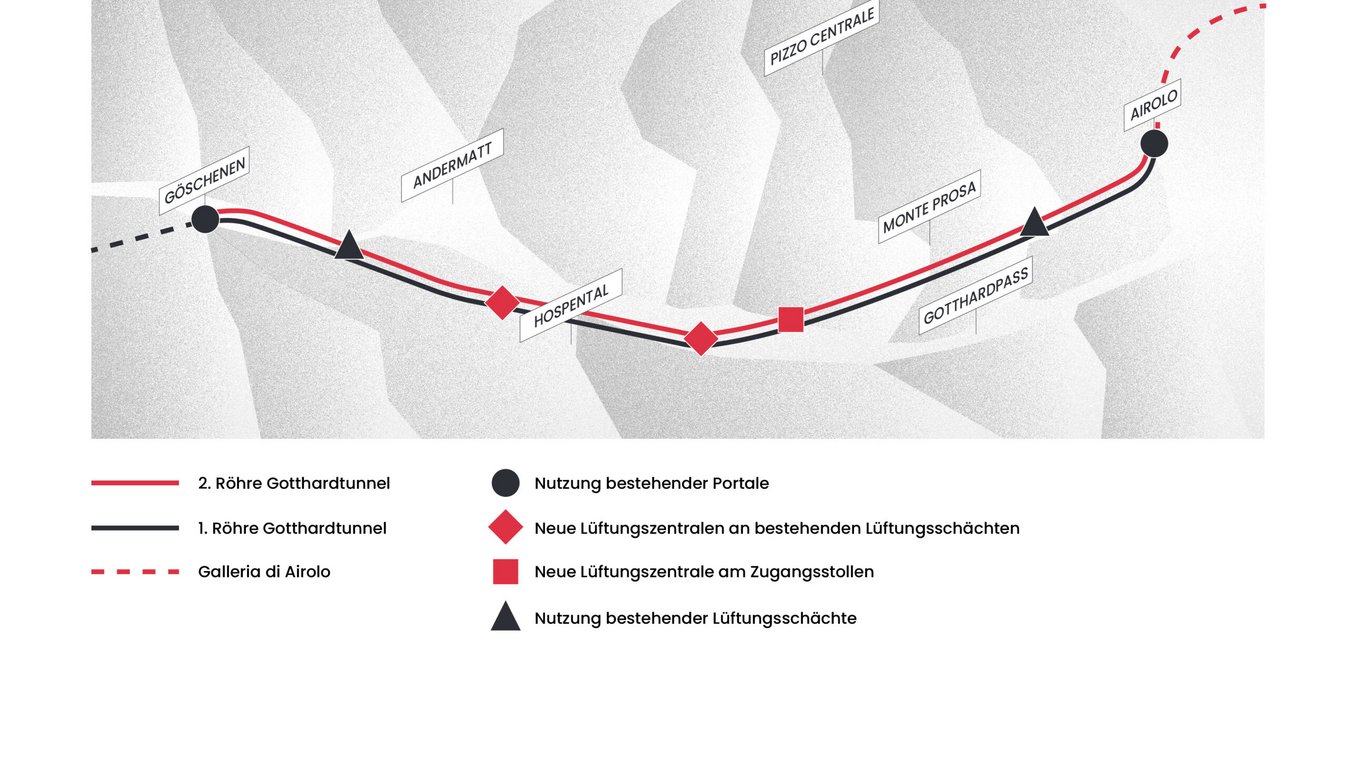

The present project includes the execution of the second tunnel tube north (2TG), the fault zone drive north, the second stage of the precut, the TBM launch section, the cross connections, the ventilation control centers and the exhibition bays.

The project

Tunnel boring 2TG is carried out with a tunnel boring machine (TBM) with single shield and segment lining up to the north fault zone. Until the arrival of the TBM in the fault zone, the fault zone excavation is carried out from the previously constructed access tunnel by means of machine-assisted full excavation with partial windows. After the TBM has been inspected in the logistics chamber of the fault zone, it is pushed through the excavated fault zone section and drives the second section up to the lot boundary.

Services in detail

In detail, the following main works will be carried out:

- Construction 2nd stage Pre-cut 2TG, excavation volume: 24'000m3;

- Loose rock section main tunnel excavation area 180m2, length 86 m;

- Construction of the underground concrete center, WELK and segment production;

- Blasting tunnel start tube TBM excavation fl. 140m2, length 421 m;

- TBM excavation ø 12.26 m, length 6930 m;

- Various blasting operations for logistics structures and north fault zone;

- North fault zone excavation with machine support in rock with flexible support in full excavation, excavation area 180m2, length 329 m;

- Various blasting drifts for cross connections/substations, length ~600 m;

- Excavation 2 central underground excavation area up to 350m2, length 86 m;

- Blasting widening of the main tunnel for 2 display bays (length 70 m each) and 10 overbursts (length 37.5 m each);

- Work for waterproofing, interior vaulting, intermediate ceiling, interior finishing, mastic asphalt and surface coating of the main tunnel;

- New construction of Göschenen ventilation center Concrete volume approx. 8,500m3;

- Material transport (reinforcement, cement, curbs, etc.) by rail.

Challenges

Construction work (main work)

- 7 km TBM-S heading (D=12.3 m)

- 0.5 km special heading through fault zone

- 2 underground ventilation stations

- 40 cross cuts

Special

- underground mixing plant & precast plant (segments & technical duct)

Geology

- The second tube Gotthard North crosses from north to south first the southern part of the Aar massif (Aare granite, southern gneiss zone) then the Urseren zone (Mesozoic with Jurassic and Triassic, Permo-Carboniferous) and then the Gotthard massif (northern paragneiss zone, Gamsboden granite gneiss). Rocks encountered: Aare granite, gneiss, calcareous schist, clay schist, sericite schist, Zweiglimmer gneiss and granite gneiss.

Sustainability

Construction of the second tube will generate a total of around 7.4 million tonnes of excavated material. 1.8 million tonnes of excavated material will be used immediately to produce new construction material. FEDRO is using around 1.9 million tonnes for terrain modeling and the overburden in Airolo. A further 3.5 million tonnes or so of rock material will be used in the renaturation of the shallow water zone in Lake Uri.