HVFD

Wood composite flat ceiling for building construction

The wood composite flat slab (HVFD) by Implenia AG and WaltGalmarini AG offers a novel, efficient and sustainable solution for wood and hybrid construction and can be used in different building types. However, due to the slim design/construction of the HVFD, the solution can develop its potential especially in high-rise construction.

The wood composite flat ceiling in a nutshell

The wood composite flat slab (HVFD) developed by Implenia AG, WaltGalmarini AG and ETH Zurich uses materials whose properties together form a high-performance slab system. Compared to classic concrete flat slabs and wood construction solid or composite solutions, the wood composite flat slab enables equivalent construction with a significant reduction in environmental impact.

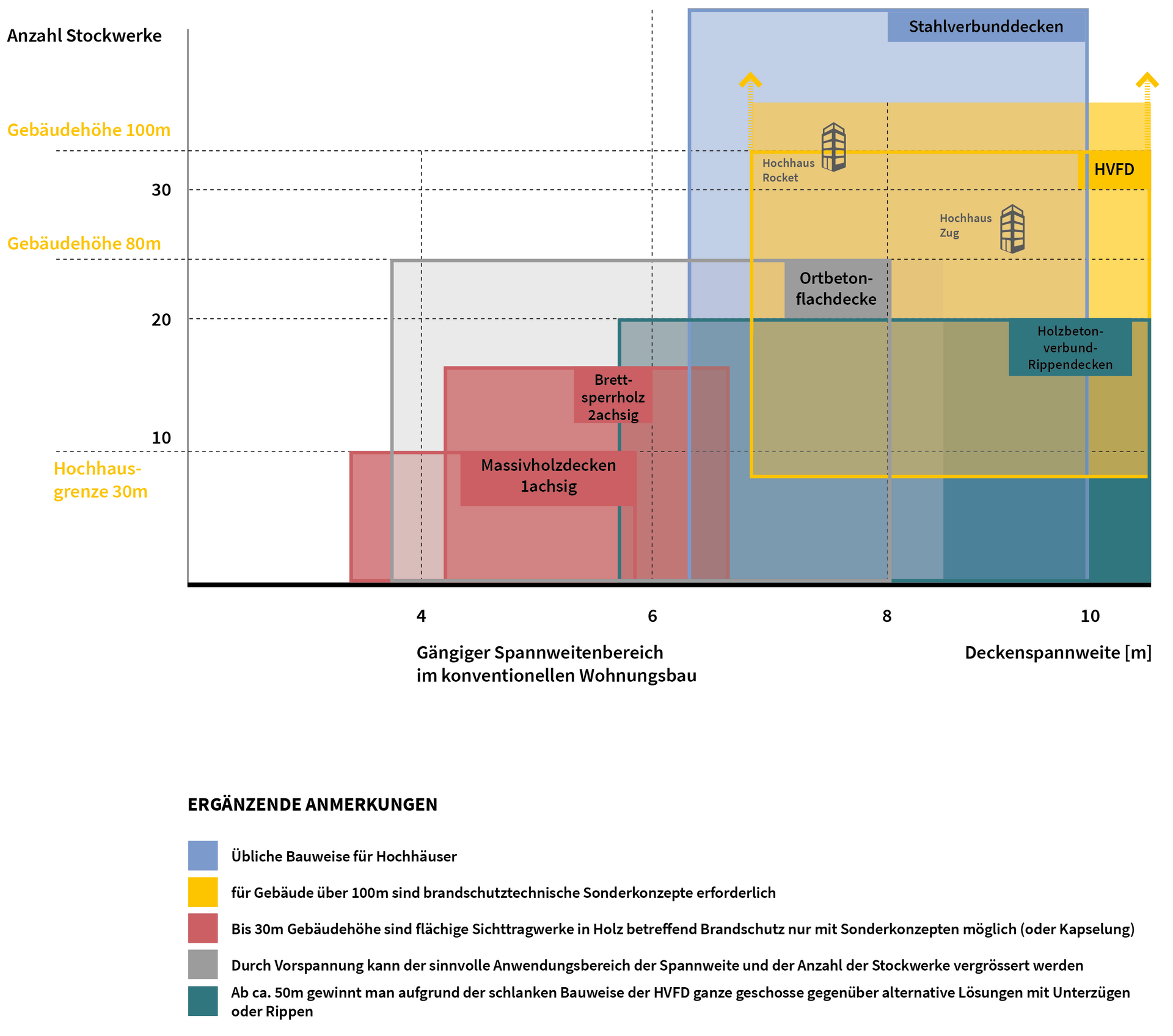

The following graphic clearly shows common applications of ceiling systems depending on ceiling span and building height. This overview is based on the consideration of the economic efficiency of the different variants and partly their technical limits due to fire, sound insulation and strength requirements. The yellow highlighted field shows the performance of the HVFD.

Why wood composite flat ceilings?

Conventional concrete flat slabs as statically acting slabs have so far optimally met the requirements for sound and fire protection as well as flexibility of buildings. In the case of concrete, however, the environmental impact of cement production will have to be taken into account to a greater extent in the future and therefore cement wastage minimized. The wood composite flat slab makes this possible.

The concrete provides the static compression zone, the mass and the fire resistance, the wood provides the static tension zone as well as design high-quality visible surface. In between, there is a filler material depending on the building physics requirements. The load-bearing layers are connected in a shear-resistant manner by vertical steel tubes.

It is our obligation to use all available resources with utmost care and to build as emission-free as possible. HVFD combines maximum performance with significantly lower material use than previous constructions in building construction.

Christoph Zimmermann Managing Director Implenia Holzbau

4 key benefits

Sustainability

The shell of buildings has proportionally the largest ecological footprint and must accordingly make a significant contribution to decarbonization. Since HVFD is about 35% lighter than a conventional concrete floor, concrete can be saved in the foundation. Greenhouse gas emissions from the shell of the building can thus be reduced by up to 40% with the use of HVFD. Thanks to material-optimized hybrid constructions, it is possible to avoid a lot of cement with little wood. This has the greatest leverage to achieve the net zero targets.

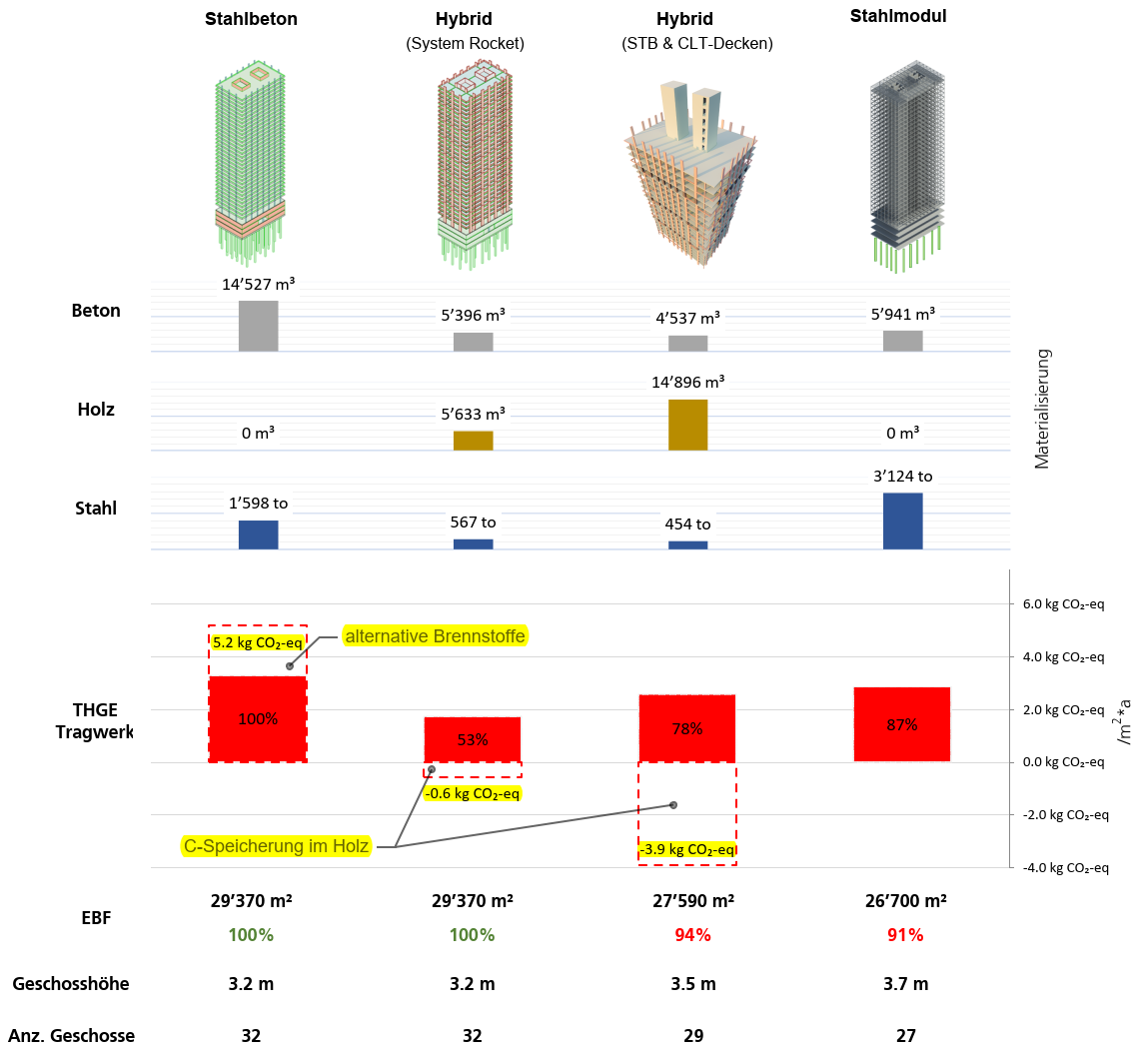

The overview shows the comparison between three different structural designs and their influence on the EBF, the floor height and the number of floors. The hybrid solution (System Rocket) is the most efficient and sustainable in terms of materials.

Legend

STB: Reinforced concrete CLT: Cross-laminated timber THGE: Greenhouse gas emissions EBF: Energy reference area

Flexibility of use across the floors

If there is a need for a wide mix of uses over many floors, slabs with large spans offer significantly more flexibility, which is a major advantage of HVFD. This is especially true for future conversions and life cycles. Environmental and financial sustainability are not mutually exclusive, but complement each other when considering integral cycles.

The figure shows the planned use of the premises in the Rocket project. The use of the HVFD allows for great flexibility in planning and use. The figure shows an example of this flexibility of use in the Rocket project. The arrangement of the apartments over the floors can be chosen arbitrarily in the floor space. Thus, the different colored units represent different apartments that can be mirrored per floor.

Quality assurance and reduction of construction time through pre-production

The use of HVFD allows faster and more efficient construction because the slab is prefabricated. Especially for urban replacement buildings, a reduction in construction time leads to less loss of rent. The consistent weather protection required for timber construction during erection is used as an opportunity: The building envelope is already assembled in parallel with the shell, which means that the extension starts several floors earlier.

Fire protection and safety

In terms of fire protection, buildings in Switzerland are classified according to their height. From 30 m, a building is considered a high-rise building. Up to the high-rise limit, visible wooden load-bearing structures are usually simply possible. Ceilings with combustible components in the supporting structure are possible in Switzerland - even in high-rise buildings - with the use of a sprinkler. Sprinklers extinguish fires very early at the point of outbreak and are thus one of the most effective methods of fighting fires. There are variants of integrating the lines in the intermediate layer as well as in the non-load-bearing ones. Project-specific and risk-based safety concepts can thus lead to increased safety at optimized costs.

We should minimize cement and not waste wood. It is important to build efficient structural systems with hybrid constructions that greatly reduce material consumption and take into account possible recycled building materials.

Wolfram Kübler Partner, Managing Director WaltGalmarini AG

Surfaces and design options

Furthermore, the wood composite flat ceiling offers a large number of design options in terms of wood-based panels:

Contact persons

Alternatively, the business card is available for download. Download VCF-Card

WaltGalmarini AG

Alternatively, the business card is available for download. Download VCF-Card

Contact form

Publications

ETH Publication: Two-Way Spanning Timber-Concrete Composite Slabs made of Beech Laminated Veneer Lumber with Steel Tube Connection - Research Collection (ethz.ch)

Article Rocket und Tigerli: Rocket and Tigerli in Lokstadt, Winterthur: Study contract for the currently world's tallest residential high-rise made of wood successfully completed (implenia.com)