Partners along the building life cycle

We help you to increase availability, reduce costs and prevent bridge closures, while we take on the entire availability risk.

Get in touch with us!Constructions in safe hands

Structural maintenance

Do you have to repeatedly close your engineering structures and carry out expensive, long-term renovation work? We can help you to increase availability, reduce costs and avoid bridge closures - with full assumption of the availability risk!

Our promise

Partners along the building life cycle

Our systematic maintenance management enables the planned service life of a building to be fully utilized or even extended by identifying and rectifying serious damage at an early stage. We are helped in this by precise and regular condition monitoring that goes beyond the standard, as well as efficient planning of renovation measures.

Thanks to close cooperation with universities and start-ups as well as an internal innovation hub, we always have our finger on the pulse and can integrate new innovations into our business without any major hurdles. This enables us to react quickly and efficiently to problems and counteract rapid deterioration at an early stage. This saves time and costs while reducing the impact on the environment.

We cannot continue as we are, otherwise we will be confronted with unforeseeable risks.

Volker Wissing

Federal Minister of Transport and Digital Infrastructure of the Federal Republic of Germany (Source: Die Zeit)

Figures in Switzerland

0

Artificial structures in Switzerland

0

% of the artificial structures are damaged

0

% of the road network under the responsibility of cantons and municipalities

Our 3-phase plan for implementing efficient building maintenance in your municipality

1. condition survey

2. concept development

3. building maintenance

Our maintenance concept is specially tailored to your building and ensures that it retains its value and long-term usability. These are the advantages of building maintenance:

- Predictability

- Extension of the useful life

- availability

- Shorter response time

We take over the structure for a fixed period of time and take care of the planning and implementation of necessary measures to ensure it is in good condition. In the meantime, we bear your risk and hand over the building in the agreed condition at the end of the contract. With our concept, we ensure the availability and safety of your building over its life cycle. If required, the structure can be equipped with innovative measurement technologies for continuous condition monitoring. Our approach minimizes maintenance costs and increases safety for users and the environment by taking into account the specific needs and requirements of the structure and being able to react immediately to damage and rectify it.

These services are available in two variants: Either as a consulting service, in which we support you with analysis, planning and implementation, or as an all-round carefree package; you show us the building and we take care of the rest. Over a pre-defined period of time, we take over all the necessary activities and ensure that the building is maintained according to the current state of the art.

White Paper Building Maintenance

With this white paper, we would like to give chief administrative officers and other responsible persons in local authorities an overview of the topic of bridge maintenance and preservation.

Innovative technologies

The right use of innovative technologies can bring many benefits, such as more precise monitoring, time savings, increased safety and cost savings.

This makes it possible to better serve the needs and requirements of our customers and increase customer satisfaction. You will find an excerpt of new technologies in the following section:

Drones

Drones enable efficient inspection without interrupting ongoing operations and easier access to areas that are difficult to see. Drones can take pictures and videos, detect cracks and damage independently using laser scanners and form the basis for a digital twin with the help of a 360° scan. They increase safety for our inspection engineers on site and enable faster and more precise recording of damaged areas.

#More precise monitoring #Increased safety #Time savings

Imaging of civil engineering structures

The condition of our infrastructure, especially the bridges, must be regularly assessed through inspections. In addition to the major main inspections, the legal requirements also stipulate visual inspections. As bridges are often located above places that are difficult to access, scaffolding, cherry pickers or under-bridge inspection equipment is required. In addition to the availability of equipment and rental costs, road closures are often required, for which the hurdles are becoming ever greater.

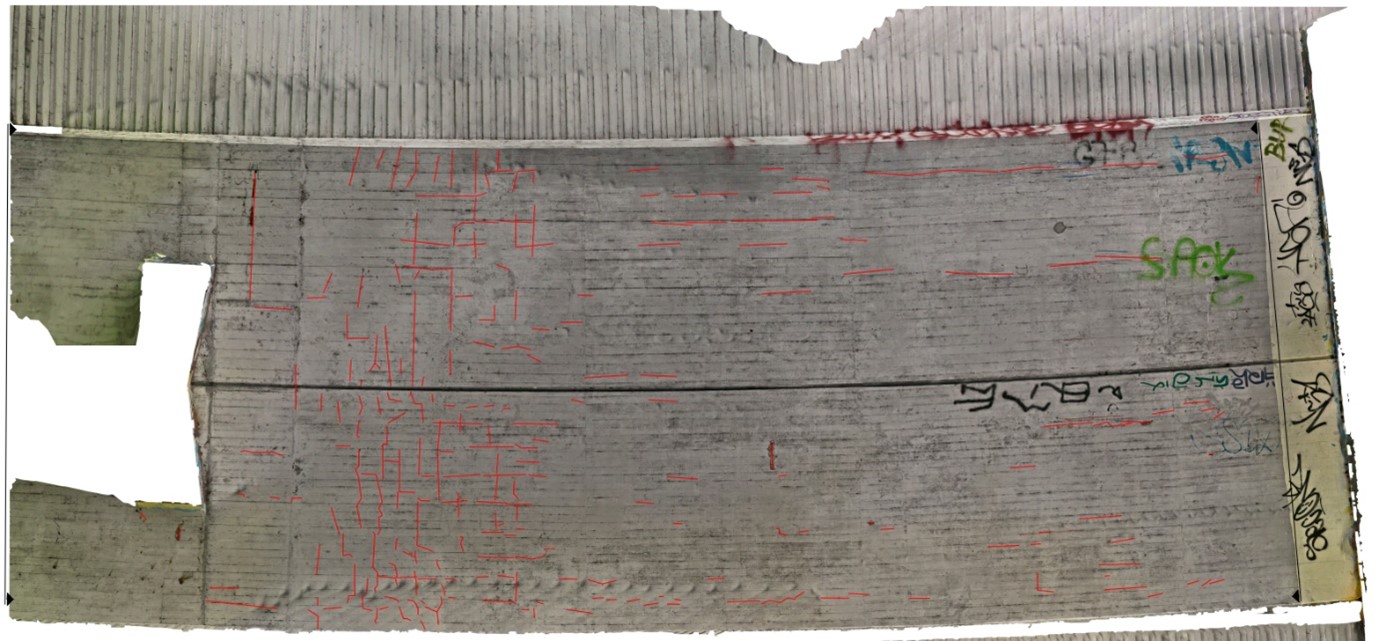

Visual inspection can be carried out using drones thanks to technological advances in recent years. Every centimeter of the structure is photographed from a distance of approx. 1.5 m and the photos are processed into a photorealistic image. From this, distortion-free, true-to-scale and highly accurate orthophotos of all views can be created, which serve as the basis for an assessment of the structure.

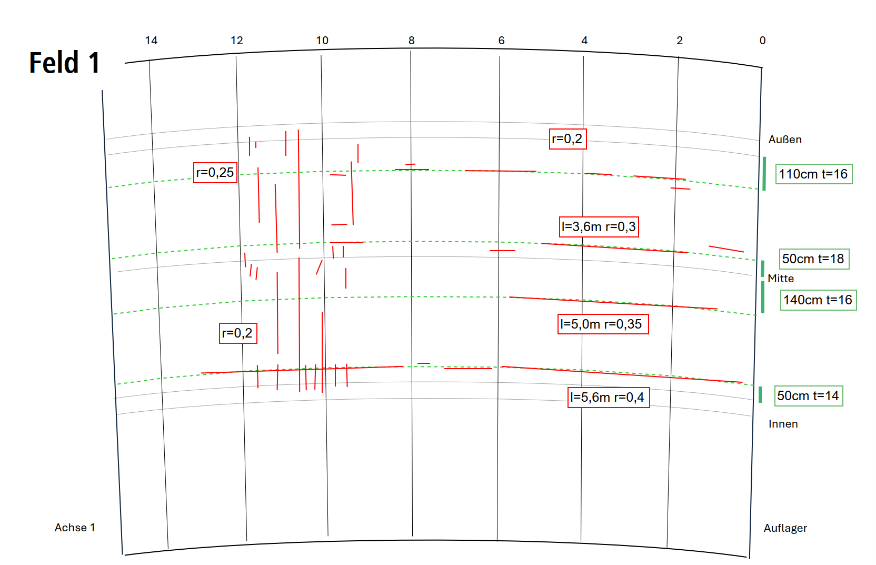

The classic crack mapping for bridges is created by the structural inspectors on a blank form and can look like this:

The cracks are drawn in approximately according to their position and noted with length and crack width. Individual photos are added to the documentation, which are used as a reference for changes in condition during the next inspections.

With a complete photo of an entire component, the entire surface can be depicted. This means that it is no longer necessary to assign individual photos to a specific location. If damage occurs in the future, it is possible to track what the condition looked like the year before. Crack developments can also be clearly tracked and can be evaluated automatically in some cases.

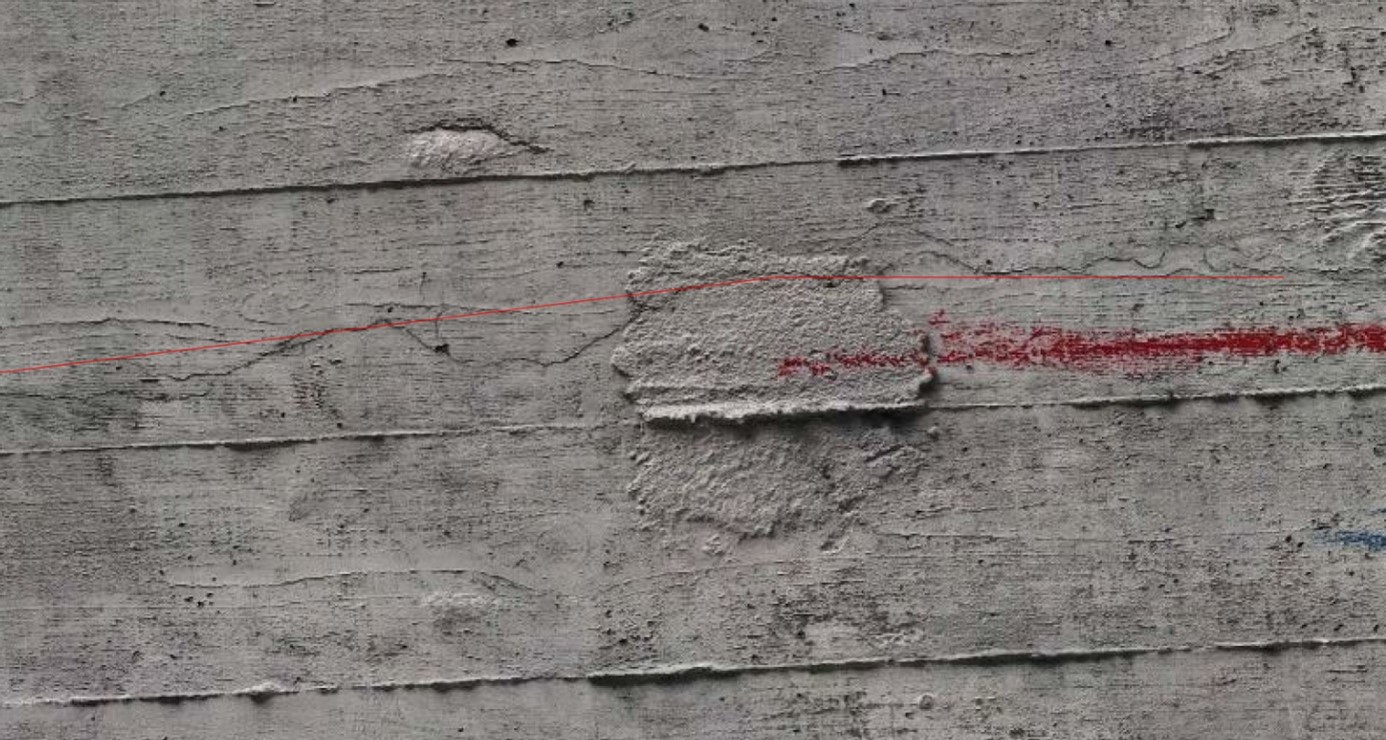

The accuracy is in the 0.x mm range, making even the smallest cracks visible on the photo.

The evaluation of these images is still the responsibility of the building inspector. They can use the orthophotos as a basis for their assessment. The scaled representation means that the largest cracks no longer need to be explicitly described, as the length of each crack can be taken from the image.

Advances in artificial intelligence also make it possible to support the process of identifying cracks. Instead of manually marking the cracks, the AI does the hard work. The marked image can then be evaluated and assessed by experts. This digitizes the process and makes it more efficient.

Digital twin

A digital twin combines the virtual image of the structure in a 3D model with real-time data from sensors and AI-supported simulations, making it possible to compare several variants of the structure's behavior in different situations. Engineers can use the collected data and analyses to simulate different scenarios in the digital twin, making it easier to make decisions about repairs and maintenance options.

#Cost savings #More precise monitoring #Time savings

Sensors

Sensors enable continuous measurement and evaluation of external influencing factors such as settlement, temperature and traffic load. This enables our experts to better assess the risks to the traffic and structural safety of the structure. The real-time use of sensors enables rapid action to be taken if limit values are exceeded. Safety risks are detected at an early stage and can be eliminated by replacing critical components.

#More precise monitoring #Increased safety #Time savings #Cost savings

AI-supported damage detection

Artificial intelligence enables automated damage detection and initial assessment of bridges using image-based methods. The detected damage is classified by type and located in the digital twin. The AI supports the structural inspectors in the final assessment and inspection of the damage and the structure.

#More precise monitoring #Increased safety #Time savings #Cost savings

Predictive maintenance

Through continuous monitoring and careful data analysis, we are able to anticipate the deterioration of a structure's condition at an early stage. Our main objective is to ensure maximum availability of the structure over its entire service life and to reduce operating costs. We achieve this through targeted planning of maintenance work. The use of predictive maintenance makes it possible to avoid unnecessary interventions, extend the service life and contribute to increasing sustainability.

#Increased safety #Cost savings #Time savings

Implenia Talk: Focus on building maintenance

In this podcast, Henning Schrewe, Head of the Civil Division for Germany, and Patrick Roth, Project Manager Innovation and New Business Models, discuss new technologies and approaches such as the all-round carefree offer for local authorities.

Contact form for building maintenance

Contact person

Alternatively, the business card is available for download. Download VCF-Card