Under the microscope

Implenia runs 30 or so large depots across Europe. They function primarily as repair and maintenance yards and material storage depots. But many of these sites also have office premises. Running these buildings, which can be very large, requires a lot of heat and electricity.

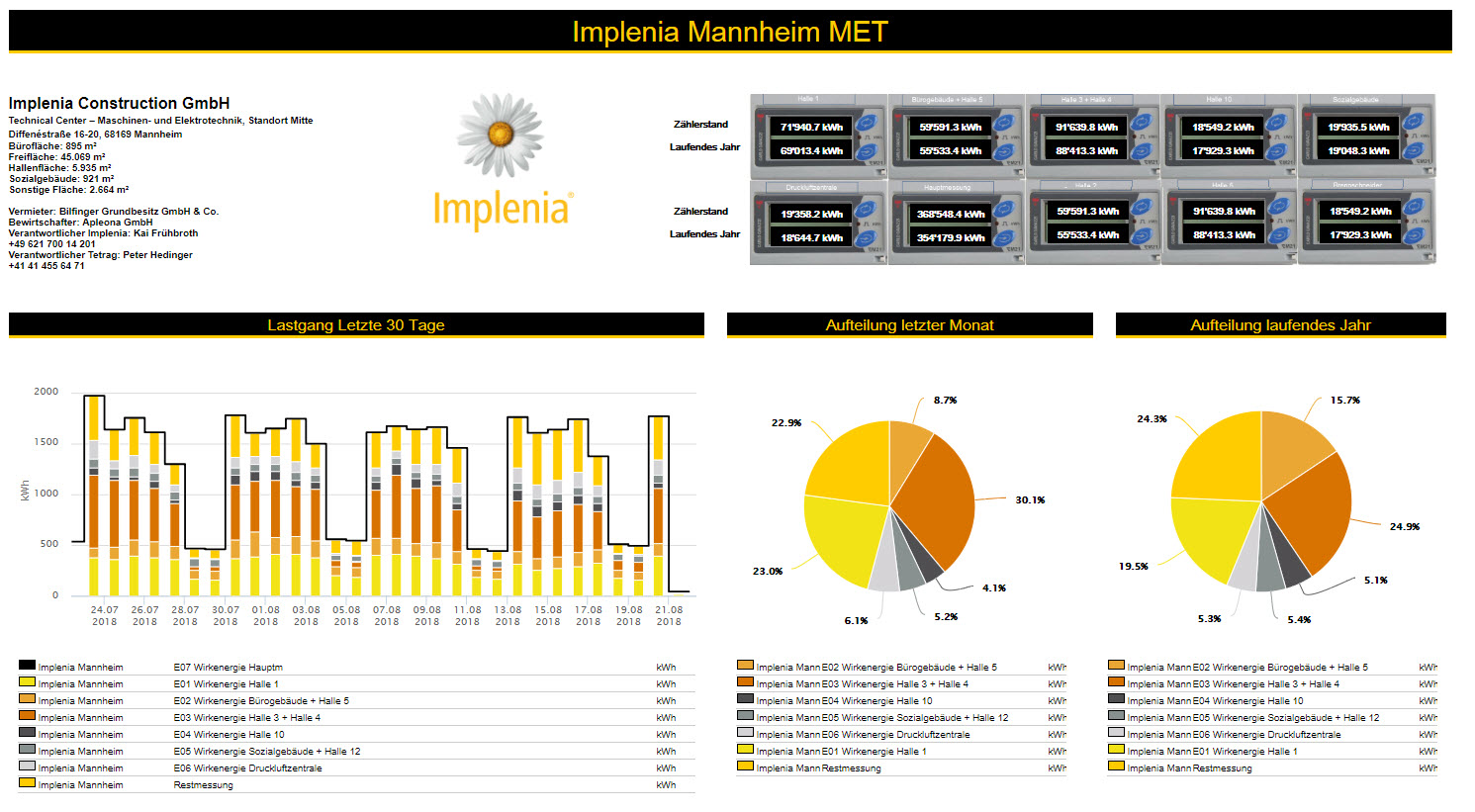

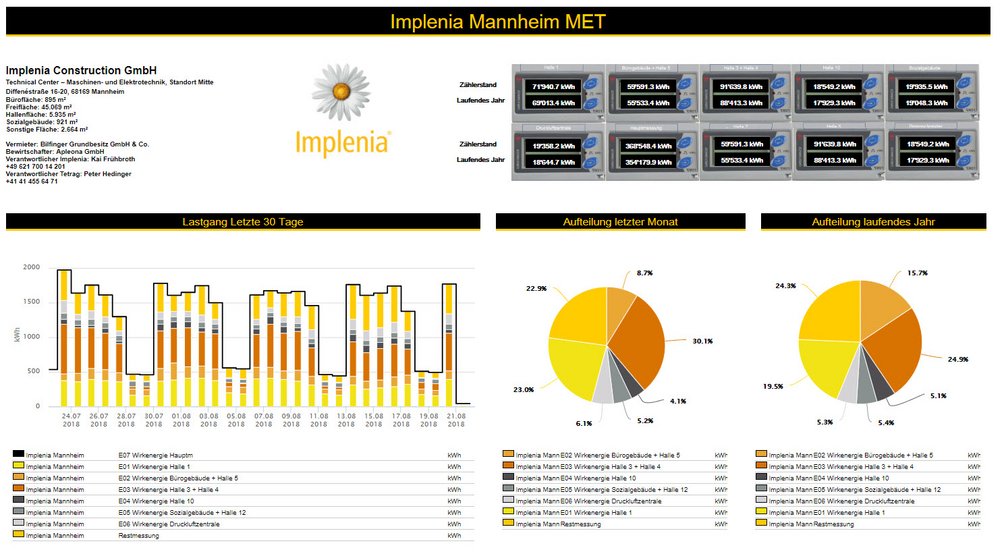

Wanting to know more about energy-saving potential at its depots, Implenia launched a pilot project that put its Mannheim facility under the microscope. As big as six football pitches, the Mannheim depot includes numerous material storage areas as well as seven buildings and halls.

The measurements were carried out by Tetrag Automation AG. This Implenia subsidiary uses the e3m energy monitoring solution that it developed itself and which is perfect for high-resolution analysis of consumption data. In December 2017, Tetrag engineers installed new electricity metres and data recording devices.

Initial analysis showed that the greatest optimisation potential is during downtimes – at night and over the weekend when no work is being done. The main way to save costs during these periods is to persuade the 45 staff at the depot to change their habits. The depot would immediately save 5,000 euros a year if all its unused machinery and equipment was turned off.

The experts at Tetrag identified a whole series of other efficiency measures, including the use of modern lighting and heating technology. Overall potential electricity savings come to 13,000 euros a year, which would pay back the cost of the project within two years. Step by step, the depot now intends to utilise this saving potential. It has already modernised its compressed air system; monitoring shows that it uses a quarter less energy than the old one.

The depot is heated mainly with district heat. The next step is to replace the measurement infrastructure, so that exact data is produced for the heating system, creating a solid basis for further effective measures.

This project is an impressive example of how Tetrag’s solutions can marry financial and environmental benefits together. Implenia intends to use the same approach in other depots soon.