Sustainability in focus

Implenia is building the eight kilometre-long Albvorland Tunnel for Deutsche Bahn. One of the longest railway tunnels in Germany, it forms an important part of the new railway line between Stuttgart and Ulm. In autumn 2019, workers on the project celebrated the breakthrough of the two tunnel bores. It took two tunnel-boring machines about two years to complete the drilling work.

As well as its exceptional length and the complexities created by the need to build a branch tunnel, the project is special for another reason: it has its own sustainability report. This contains details of the measures taken and successes achieved on the construction site – like the fact that around 4 million litres of fresh water was saved by treating concrete scrubbing slurry. As a result, concrete could be produced using around 20 percent less water than usual.

Compacting the excavated material also proved a highly effective environmental measure. It meant that the pyrite-containing rock could be disposed of at nearby landfill sites, thus cutting CO2 emissions. Implenia also plans to fit its own vehicles on the site with retread tyres. These only require a fifth of the rubber used in new tyres. In addition, Implenia is planting 50 long-living, climate-resistant trees.

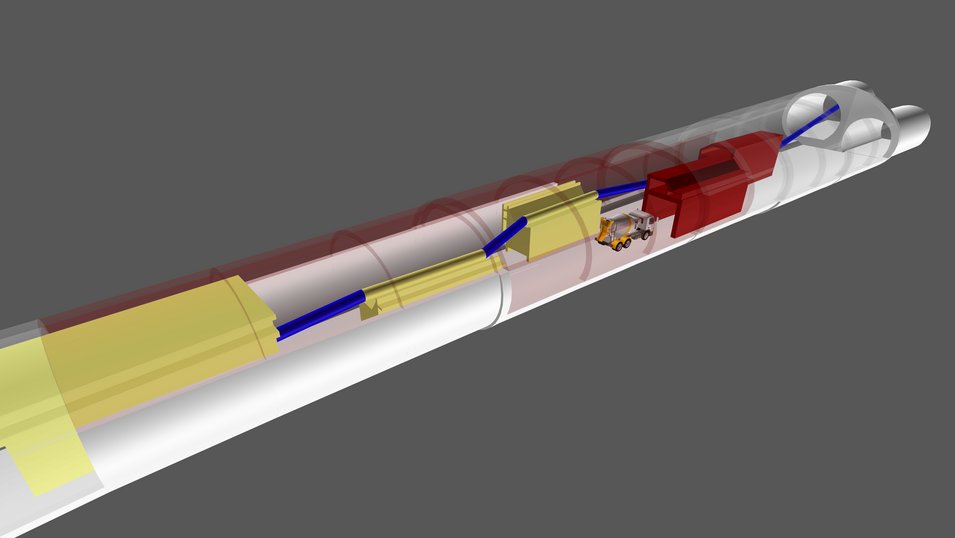

The Albvorland construction site is one of the first projects that Implenia has optimised using fully digital planning methods. The complex linkage between the two bores, through which trains will speed at 250 kilometres per hour, is being planned and executed using BIM (Building Information Modeling). This allowed our specialists to plan out the underground work processes in detail even before the first spade went into the ground. Such meticulous planning helps greatly to avoid problems once construction is underway and to make the whole process more sustainable.