Sustainable timber construction in large: Rächtenwisen cargo hangar

The Rächtenwisen cargo hangar at Zurich Airport is an impressive new freight infrastructure. Implenia Holzbau implemented the project on behalf of Flughafen Zürich AG – and once again demonstrated how efficient sustainable timber construction can be.

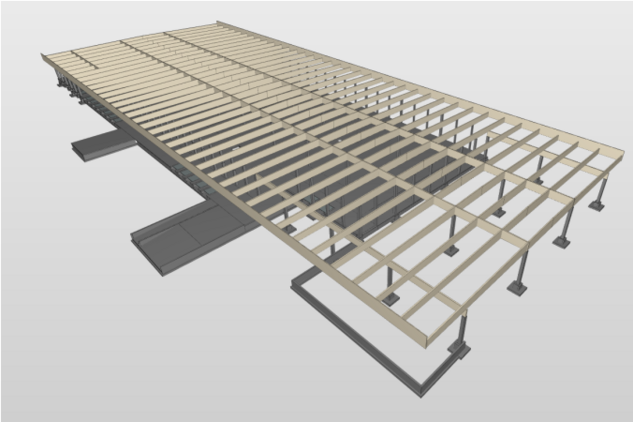

11.30 p.m., Zurich Airport. Air traffic is at a standstill. Instead, huge wooden beams float through the air. For the construction of the new Rächtenwisen cargo hangar, a large pneumatic crane is lifting 20-meter-long glulam beams. They form the supporting structure for a building that sets new standards in freight infrastructure at Zurich Airport and shows how the use of wood can also make large industrial and infrastructure buildings sustainable and fit for the future.

Flexible use thanks to large spans

With the new hall, the client, Flughafen Zürich AG, wants to meet the new requirements in the freight business with increasingly small, highly varied goods. A single-storey warehouse with two-storey fixtures for offices and technical rooms is planned. The planning focused on large spans. The construction method is also forward-looking in other respects: the freight hall is planned as a high-performance concrete column construction with a timber supporting structure, executed by Implenia Holzbau.

Planning to the millimeter

The dimensions are impressive: The main dimensions are approx. 151 x 62 m, the roof area including canopies measures approx. 181 x 71 m. The roof structure consists of the aforementioned glulam beams, up to two meters high and 31 meters long, which are supported on prefabricated concrete columns in a grid of five meters. In addition, the roof structure comprises a total of 12,600 m² of prefabricated ceiling elements, manufactured by Implenia Holzbau.

"The logistics of this project are very complex, and the working time with the lifting equipment is limited due to airport operations," explains Beda Weber, Head of Implenia Timber Construction. "Every step requires millimetre-precise coordination and perfect planning." It is particularly challenging to synchronize a large number of deliveries in a short space of time. The large-format beams are only assembled at night between 11.30 p.m. and 5.30 a.m. so as not to disrupt airport operations. The roof elements are installed during the day and at night. "This is real teamwork, day and night," says Beda Weber. The construction phase for the timber construction is expected to last until the end of spring 2025.

Improving the CO2 balance with timber construction

An outstanding feature of this project is the timber construction method, which is becoming increasingly popular in large infrastructure projects. And with good reason: the use of timber as a central building element for the roof structure makes a significant contribution to reducing CO2 emissions and to sustainability. The lightweight timber supporting structure replaces heavy solid or steel construction methods. This significantly reduces energy consumption during the construction phase. In addition, wood is a renewable raw material that stores CO2 as it grows. Overall, this improves the CO2 balance of buildings. This is a particularly interesting factor for companies that want to optimize their ESG compliance.

The Rächtenwisen cargo hangar provides an important impetus for the entire construction and industrial sector. The project impressively demonstrates that timber construction is not only sustainable, but also efficient – even for the most demanding infrastructure projects.

Further information on the project

The project is being realized in close cooperation with the following partners:

- Client: Flughafen Zürich AG

- Planning: Gähler und Partner AG

- Executing timber constructor: Implenia Holzbau

Cover picture: © Flughafen Zürich AG