The BIM train picks up speed in Lokstadt

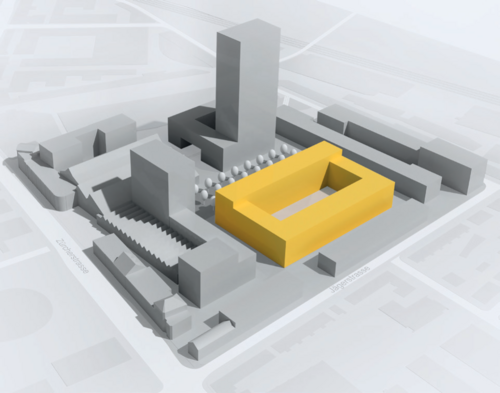

With Lokstadt, a modern counterpart to the old town is being created in Winterthur. The new, urban district on the site of the former Swiss Locomotive and Machine Factory SLM marks the beginning of a new era for the Swiss construction industry. In the case of the Krokodil timber building, the entire planning process is being carried out for the first time in a central, three-dimensional data model. The participants in the architecture competition were already required to submit their projects as BIM models.

Pilot with competent support

"The Crocodile is not only a BIM pilot project for us," says Lukas Besser, who is responsible for the use of BIM at Implenia. The architectural firms also broke new ground with the competition for the first building in the Lokstadt. Implenia offered targeted support to ensure that all competition participants had an equal footing and to obtain submissions that were as comparable as possible. Each office was able to book two consultations with Implenia specialists. Besser is convinced that Implenia's concentrated BIM expertise is a decisive factor in the project's success: "Our team now comprises eight experts. All divisions of the company and our partners benefit from this centre of excellence."

Measurable advantages already in competition

BIM already brought a measurable improvement in the competition phase: the inputs could be checked more easily and quickly using the three-dimensional model data and the quality of the evaluation was much better compared to 2D plans. "Central characteristic data, such as the usable floor space or the housing mix, can be determined accurately from a model based on rules. Previously, only estimates could be made based on the 2D plans," Besser explains. Just how great the advantages were is shown by the fact that Implenia now requires BIM for all competitions it puts out to tender as a building owner.

All trades integrated with Open BIM

After the competition, the BIM model was refined from the preliminary project to the execution and enriched with more detailed information. In the process, the planning for all trades was integrated into the model. For Lukas Besser it is clear: "BIM must be as open as possible. The various planners should be able to use their own software. That's why we work with Open BIM." He sees the biggest benefit of this approach in the much better cooperation: "On the one hand, all those involved have to sit down together right from the start and define the goals with each other. On the other hand, the three-dimensional model helps to create a common understanding of the building." As a result, one hopes for a higher quality of planning and fewer costly mistakes in the execution.

Acting with foresight thanks to models

The improved planning pays off in all project phases. Based on the BIM data, the construction and use of the building can be fully simulated and optimised in advance. For example, before implementation, the project costs can be determined more precisely on the basis of the model and criteria such as sustainability can be checked more accurately. In the same way, BIM - especially in combination with lean methods - also makes the construction phase more efficient. This ranges from optimising logistics and assembly to more precise monitoring of construction progress. Even after completion, the 3D data provide measurable added value, for example in the management and marketing of the buildings.

Keep it as simple as possible

Naturally, everything did not yet function optimally in the pilot project. "BIM requires different processes," as Lukas Besser explains. "Figuring out who does what, when and how best was one of the biggest challenges." Among the lessons learned from Crocodile Planning is that the level of detail in the models should be kept as simple as possible at every stage. For example, only the areas and spatial relationships, but not detailed information, are necessary for the assessment of competition entries.

Step by step to the construction site

Besser is curious about the execution: "It is not yet clear to what extent the BIM models will also be used on the construction site. Conceivable applications would be model-based performance reporting to monitor construction progress." Whether this will be possible depends above all on the capabilities of the companies that create the respective trades. Implenia Holzbau will also play a pioneering role in this respect.

Interview with Fridolin Oberholzer, foreman at Implenia timber construction

Mr Oberholzer, do you feel the digitalisation in your daily work?

It has changed our work a lot in recent years. Today, plans are available to me on my laptop as 3D models or I receive them as PDFs by email. The measurement of the construction site is also largely digitalised. The measurement data is displayed directly in the model.

What are the advantages?

When we discuss our goals for the day in the team in the morning before work, I can, for example, send a carpenter the plan of his work area directly to his mobile phone. He always has it with him and can consult it easily and quickly. For more complex tasks, I can use the 3D model. It shows me all the construction details. This way I can find out exactly how a particular construction is planned. In the past, if something was unclear, I had to call the planner and ask him to explain what he meant. There were more misunderstandings and more mistakes.

Does digitalisation mainly affect the plans?

No, digital technologies are used in practically every area today. Let's take inventory. Today, I photograph the QR code on a machine and it is immediately recorded. Before, we had to keep paper lists, which were then entered into the computer. This took a lot of time and the inventory was never really up-to-date. Today I know immediately where the machine I'm looking for is.

How does the work change for your team members?

It becomes more demanding because you have to master all the technologies. But that also makes the work more interesting. In any case, everyone is always on fire when we get a new digital instrument. For example, measuring with the digital theodolite, an angle measuring instrument, is an extremely popular task today.