Implenia Timber Construction realizes first parking garage with wood

Implenia built Switzerland's first wood-concrete parking garage in Dübendorf for the Swiss Federal Institute for Materials Research (Empa). The project shows that more environmentally friendly construction methods can also be implemented on a large scale.

A new campus consisting of a laboratory and a multifunctional building with parking garage is being built on the Empa-Eawag site in Dübendorf. Under the overall management of Implenia, SAM Architects and Andreas Geser Landscape Architects have designed the individual structures, incorporating new findings from science. In Dübendorf, for example, Implenia Timber Construction built the first wood-concrete parking garage in Switzerland.

Proven building material

The renewable raw material wood, which has long proven itself as a building material, is an obvious alternative to concrete. One cubic metre of wood binds about one ton of CO2 from the atmosphere and thus relieves the climate. Stefan Zahnd, site manager at Implenia Timer Construction, explains: "There were no car parks made of wood in Switzerland yet. But once the statics have been precisely calculated and checked, wood is a reliable raw material for car parks too".

800 cubic meters of beams installed

If anyone knows it, it's Empa. As part of the ETH Domain, the Swiss research institution is dedicated to materials science and technology. It is remarkable that an expert in materials and their properties is integrating the first hybrid parking garage into its premises. Hybrid, in this case, stands for a mixture of wood and concrete. The building has space for 260 cars and houses the company's own fleet, including a service station, garage and car wash. An earth probe field under the building stores waste heat and makes it possible to use it later as heating energy.

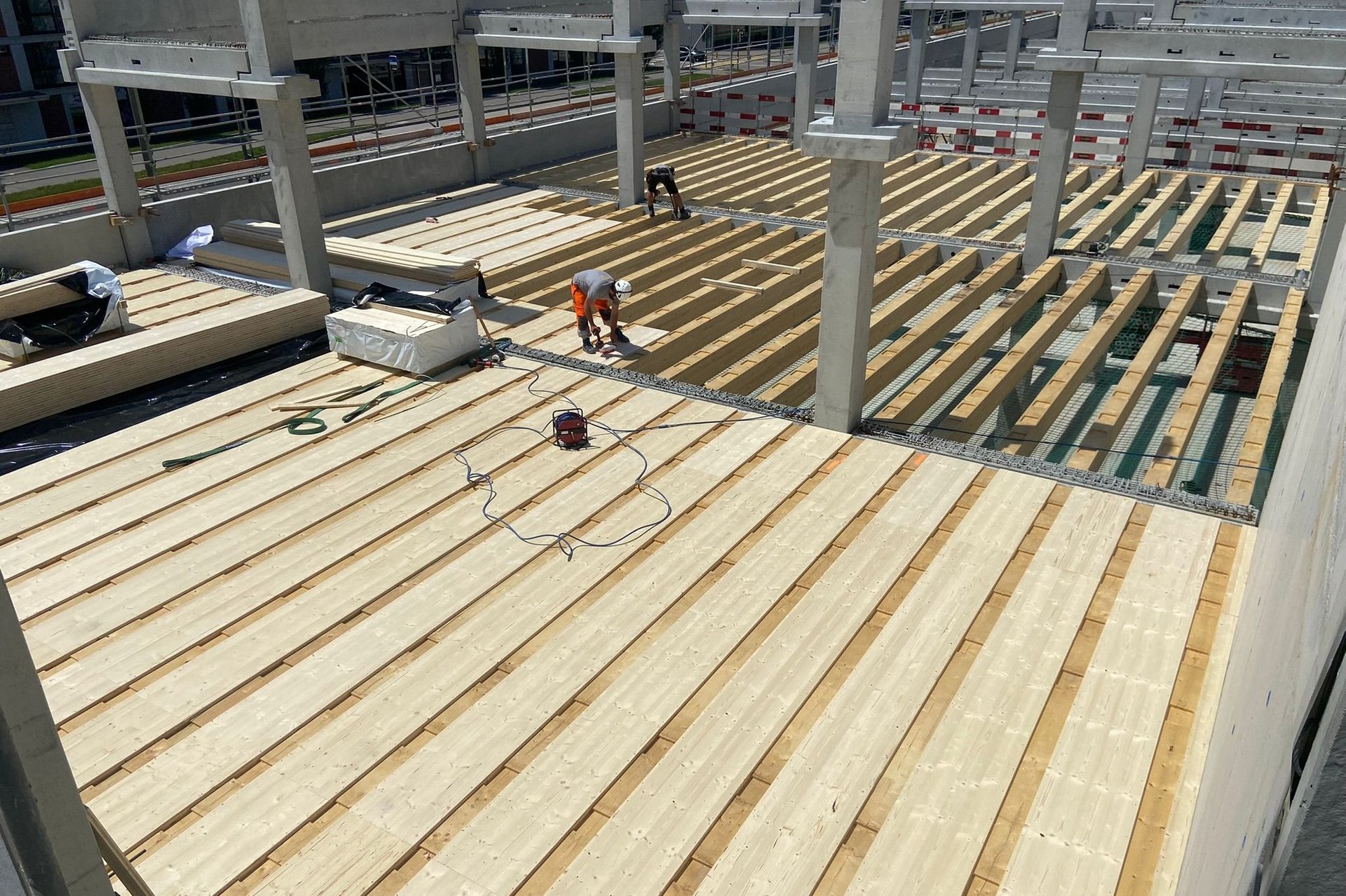

An on-site inspection proves Empa right: the wooden facade looks friendly, warm and inviting. The floors still have a concrete layer, but according to Zahnd, it is only a third as thick as usual. That's because there is also engineered wood underneath. "We installed 800 cubic meters of beams, laid 10,000 square meters of three-layer panels and put in countless screws," says the foreman in charge of the project. By we, he means his team of four people, who, thanks to the elimination of drying time and the prefabricated wooden elements, were only busy with the Minergie parking garage for six months. Since the areas would have been too large to pour concrete all at once, progress on the three slabs was made in stages. The pioneering project was finished on time by the end of the year.

Wood classic served as a building material

The wood species used was the Swiss classic among woods: spruce. Compared to other woods, this coniferous wood is very load-bearing and elastic and can be processed very well and precisely. The fact that spruce is considered to be particularly load bearing naturally benefits the parking garage. Spruce - also known as spruce - is found in almost all Swiss forests and grows at low altitudes as well as at 2000 meters above sea level. As an untreated natural wood, it will darken somewhat in the first few months in Empa's Dübendorf parking garage and - caused by the UV rays - acquire a pleasant tint.

The shift towards more ecological construction methods is in full swing. The trend is clearly going in one direction: "We sense that wooden buildings are increasingly in demand," says Stefan Zahnd.