Managing complexity with a local solution for closed material cycles

Circular economy, Waldenburgerbahn Basel

The “Waldeburgerli”, Switzerland’s narrowest-gauge railway, is being widened as part of a general refurbishment of the line, which runs through the Waldenburg valley. This project is notable for its complexity, but also for its regional approach to creating a closed material cycle.

Facts & Figures

PROJECT DESCRIPTION

The “Waldeburgerli”, which runs through the Waldenburg valley in Canton Basel-Landschaft, was the narrowest narrow-gauge railway in Switzerland for 140 years. It is now being widened from a 75 to a 100 cm-wide track as part of a general upgrading of the line, due for completion in 2022. The refurbishment includes everything from the tracks and trackbeds, to rolling stock and stations, to the terminal station at Waldenburg. Improved flood protection and the renaturation of the Vordere Frenke river also form part of the project.

The 13 km long route between Altmarkt and Oberdorf is divided into seven lots. Implenia has been commissioned by the client, Baselland Transport (BLT), to handle Lot 6.1 in Niederdorf and Lot 0 as part of the four-track expansion in Liestal. The services Implenia is providing include installation of utility lines, road construction, earthworks, concreting, special foundations and hydraulic engineering.

Worth CHF 47 million, Lot 6.1 is the largest and most challenging section. Work has been going on since autumn 2020, with an intensive construction phase between April 2021 and December 2022 while the railway is closed. Finishing works will be done in the first quarter of 2023 when the trains are running.

According to the cantonal risk map, the Vordere Frenke in Niederdorf does not currently have sufficient flood protection. Since the course of the river has to be shifted anyway as a result of Waldenburgerbahn re-gauging, this issue will be sorted out by widening and deepening the river bed. This will provide better protection against high water levels.

> 100 t/h

gravel plant capacity

35’000

m3 excavated material processed by the plant so far, which is equivalent to more than…

2’000

truck loads

~ 10’000

truck trips will have been saved by the time the three projects using the gravel plant come to an end

300

m3 water are required for the operation of the plant in a closed system

Circular economy thanks to semi-mobile gravel plant

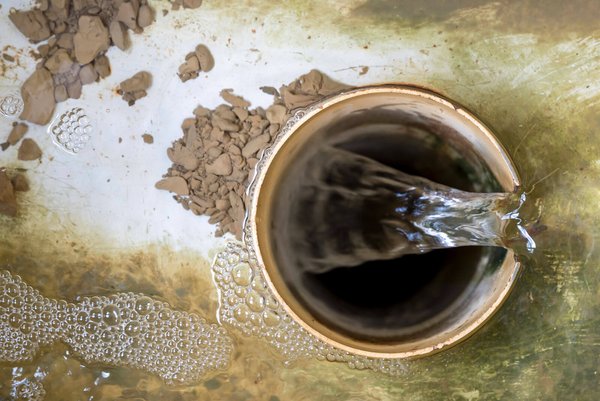

Apart from its sheer complexity, one of the most impressive features of the “Waldenburgerbahn” project is the regional solution it is using to create a closed material cycle. In Nuglar (BL), close to the construction site, a plant has been set up to prepare materials for three projects: the Liestal four track expansion, the Waldenburgerbahn and Dreispitz Basel. It’s a great practical example of how a closed material cycle can be achieved.

RECYCLING MATERIALS LOCALLY

Implenia has invested more than CHF 3 million in the semi-mobile gravel plant, which can be dismantled when the projects are finished and used again at another location. Excavated material is delivered to the plant, where it is washed and graded into different sizes. Around 90% of the material is prepared in this way and then returned to the same construction site for re-use as standardised aggregate.

This circular economy concept showcases Implenia’s competence in sustainability-related matters. By recycling building materials, the company uses fewer resources, as well as cutting CO2 emissions by reducing the number of truck journeys. The volume of excavated material that has to be deposited is also significantly reduced, as is the cost of materials.

Sustainability

Suitable material excavated during the earthworks is turned into certified type UG 0/45 gravel mix at the gravel works in Nuglar, and then re-used at the construction site in Niederdorf or the four-track expansion site in Liestal. This reduces landfill volume, materials transport and primary material consumption.

Challenges

«Lot 6.1 is the most technically complex section of the new Waldenburgerbahn. Implenia has proved its expertise and competence on such challenging construction projects many times. This is why we decided to bring Implenia in as a strong partner for this particular section.»

Reto Rotzler

Head of Infrastructure BLT

Other top projects

Semi-Annual Report 2021

Circular economy, Waldenburgerbahn Basel

The “Waldeburgerli”, Switzerland’s narrowest-gauge railway, is being widened as part of a general refurbishment of the line, which runs through the Waldenburg valley. This project is notable for its complexity, but also for its regional approach to creating a closed material cycle.

Read more

Developing and building in partnership, Südcampus Bad Homburg

In Bad Homburg am Taunus, Implenia is realising the "Wohnquartier am Südcampus" project for the developer Wüstenrot Haus- und Städtebau (WHS). The job is being executed within a two-stage partnering process. Together with WHS we developed, planned and optimised the project together with the client from the very first phase.

Read more

Integrated Project Delivery, Schaffhauserstrasse Zurich

Implenia wants to promote new partnership models for greater transparency and efficiency, and is launching pilot projects that use Integrated Project Delivery (IPD). A new project to build a multi-family dwelling on Schaffhauserstrasse in Zurich is just getting under way.

Read more

Sustainable construction site logistics, Arnulfpost Munich

Sustainability has to be planned properly – and optimised construction logistics plays an important role. But can construction logistics really help us achieve a successfully sustainable future? The “Arnulfpost” project in Munich shows how Implenia approaches this highly complex task.

Read more