![[Translate to en-CH:] [Translate to en-CH:]](/fileadmin/_processed_/7/5/csm_IMP_GB2020_Winterthur-Lokstadt-1570-1_spa_16338db117.jpg)

[Translate to en-CH:]

[Translate to en-CH:]

Insight: Added value through innovation

Implenia decided early on that it should take a lead in the transformation of the construction industry, and use our technical potential to bring customer-focused innovations to market.

Stefan Verling had only been working as a project developer for three months when he submitted his first idea to the Innovation Hub. “When I was studying architecture, I asked myself how you could change the way we plan so you don’t have to start from scratch every time. My answer was to think more from the product and less from the project perspective.” If you’re focused on products, you have to know your target group, which is how Verling came up with the idea of “target group-oriented residential products” at the end of 2019. “This is the spirit we need,” says Innovation Manager Karel van Eechoud. “We want to support and accelerate talent and ideas. This means being happy to try things and possibly to make mistakes, i.e. to take calculated risks: trying things out and learning is a large part of the innovation process.” Thousands of Implenia employees spend every day working on real estate and infrastructure products, and they are always asking themselves how things can be done even better. One of the tools that Implenia uses to nurture this intellectual capital is the Innovation Hub – a Group-wide kick-start programme that validates employees’ ideas and suggested improvements, and develops them with the help of coaching and resources.

Establishing agile processes

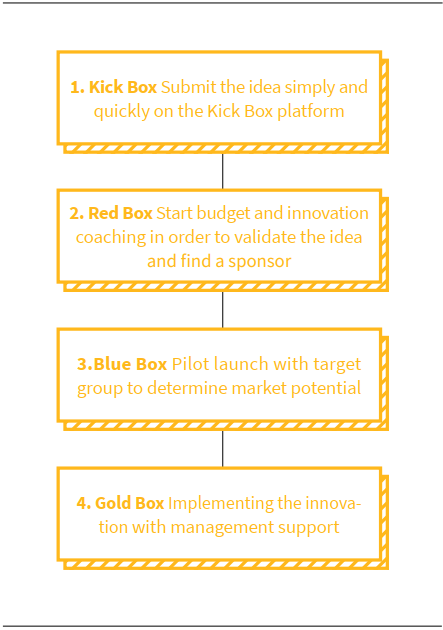

Every idea is valuable, but not all of them have market potential or fit with Implenia’s strategy. So that is the first thing to clarify. Once this first hurdle is negotiated successfully, we use the Innovation Hub to provide tools and resources at speed. The result is an agile process, inspired by Lean Innovation philosophy, that includes coaching, market testing and implementation. It also involves cooperation with external innovation experts.

“Innovation is often confused with progressive trends such as digitalization,” says Karel van Eechoud. “But actually innovation happens at the interface between ideas and technology. The trick then is to translate an innovative approach into a product or a service.” Responding quickly to the market, data-based testing and agile implementation – Design Thinking is one of the effective ways of incorporating the needs of potential customers into the innovation process. After all, what use is the best product if no one needs it? We aim to provide real added value for our customers, even if this means adapting the idea as we go along. Karel van Eechoud: “This is part of the innovation process. You only learn if you are prepared to make mistakes and fail.”

“Innovation means being open to new ideas, thinking flexibly and working hard.”

Karel van Eechoud

Senior Innovation Manager andHead of the Innovation Hub

Happier living

Stefan Verling and his team certainly learnt an important lesson from the initial burst of activity, which led them to change their original approach. The team realised that every community has different requirements, so rather than starting with the building, the process has to start with people’s needs: what is possible on this site and what do the people who live here need? This customer-oriented approach might seem obvious, but it is still not common in the real estate and construction industry. Most property development is based on statistical data from the past. Stefan Verling: “But we want to collect up-to-date, concrete data, so we ask the relevant target groups about their needs and challenges.” The insights gained are then incorporated into the architects’ briefing or translated into specific design elements, such as built-in cupboards. Ulf Hoppenstedt, Project Development Team Leader at Lokstadt in Winterthur, saw the potential immediately: “The earlier we bring customers into a co-creation process, the more accurately we can plan appropriate real estate products. We’re not building for us, but for the people who will live there.” The result: more happiness per square metre. This approach is particularly effective on projects that Implenia initiates itself. Like the Lokstadt neighbourhood development in Winterthur. Rocket, a Lokstadt apartment block that will be completed in 2025, was a perfect building to discuss in advance with potential residents. A campaign of online advertising and direct mail persuaded 13,400 interested parties to visit the landing page. More than 500 of them have registered their details on the website so far. The data is currently being evaluated and there is a good chance that Stefan Verling’s customer-centric approach will become a fixed part of Implenia’s development strategy.

“Cooperation with innovation experts has greatly accelerated the development process.”

Stefan Verling

Project Developer

Creating genuine added value

The internal innovation process is undoubtedly motivating and inspiring employees to get actively involved: 62 ideas were submitted to the Innovation Hub in just its first year. Karel van Eechoud believes it is a big step in the right direction: “You can only promote innovation in the long term. And you do it by rewarding entrepreneurship, establishing a positive error culture and reacting positively to external stimuli.”

The Innovation Hub -

Promoting internal innovation in 4 steps

But not all ideas end up in the Innovation Hub. Innovative products often emerge in the course of a construction project or when there is a concrete problem to solve. The “Pi” high-rise in Zug is a good example. At 80 metres and with 27 floors, this will be the tallest wooden building in Switzerland. It is being built by Implenia as main contractor, along with architects Duplex and engineers WaltGalmarini. Social and environmental sustainability lie at the heart of this project. Instead of a concrete core, the tower block has a double-frame structure made of beechwood. The challenge was to keep the total static load to a minimum. The solution was developed by Implenia’s Timber Construction team in cooperation with the civil engineers at WaltGalmarini: a composite wood ceiling that only uses 80 millimetres of concrete. Adrian Ulrich, Team Leader at Timber Construction, explains what this means: “Our structure is not only lighter than conventional concrete ceilings, but also significantly thinner. This meant we could accommodate an additional floor within the prescribed maximum height of 80 metres.” Less concrete, more living space – a product innovation with real added value. The patent is pending.

Responding flexibly to the market

For us, innovation culture also means being right at the forefront of new trends and technologies. We are continually testing and evaluating to see what will create genuine added value. “As a Group-wide organisation, we work across all the divisions on optimising work processes. We do this in close cooperation with local units,” says Johannes Müller of Project Excellence & Services.

Digital tools on construction sites

As the industrialisation of construction processes continues, “Reality Capturing” by means of digital tools such as drones and mobile 3D laser scanners is becoming increasingly important. The more we know about the starting conditions, the better we can plan, produce modules and build. To find out what works best, we evaluate different tools and methods in collaboration with our construction site teams, and then we adopt the most effective option as the standard approach. Johannes Müller: “It’s impressive to see what becomes possible when you combine scanned data with BIM modelling, for example. Deviations in progress and quality are made clear, allowing us to respond quickly to inconsistencies. This saves time and resources.”

Definitions/explanations

Reality Capturing Recording the starting situation by scanning an object, building or whole site. This could be done with drones, for example, or with stationary or mobile 3D laser scanners. The result is a high-precision 3D image based on millions of individual data points. The terrain or structural data, for example, can then be integrated into the digital project development and planning process. Automated target-actual analysis using artificial intelligence is being used increasingly during project execution to steer the co-ordination of individual construction stages and improve the quality of implementation.

![[Translate to en-CH:] [Translate to en-CH:]](/fileadmin/_processed_/4/8/csm_IMP_GB2020_Green_Village__Genf_High_Res_3186_spa_161f9882a1.jpg)

![[Translate to en-CH:] [Translate to en-CH:]](/fileadmin/_processed_/1/f/csm_IMP_GB2020_210005-14_spa_d7e5dd646b.jpg)

![[Translate to en-CH:] [Translate to en-CH:]](/fileadmin/_processed_/1/3/csm_IMP_GB2020_KIM_Winterthur_High_Res_3683_spa_9a742a5478.jpg)