Environment

Sustainable construction Waste, noise and dirt are features of every construction site. As Project Manager Sustainability, Bernadette Arbogast looks for environmentally friendly methods and materials – and encourages project teams to use them. A good example is wood-pellet construction heating, which produces 90% less CO2 than oil-powered alternatives.

“The thing that excites me about my job is that my work helps us build the world of tomorrow in an environmentally friendly way.”

Bernadette Arbogast

Project Manager Sustainability and ambitious activist for lower CO2 emissions

Promoting employee engagement through recognition: You Matter

A variety of measures to protect the environment

One of the Global Sustainability unit’s main jobs in 2021 was to create transparency for various sustainability goals – through knowledge transfer and by developing new sustainability indicators. This transparency is a prerequisite for taking concrete action from 2022 onwards. Measures for other goals have already been developed and introduced.

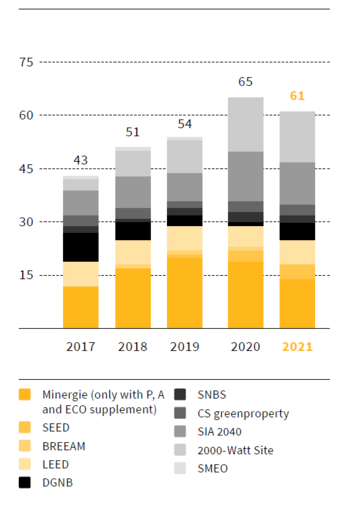

Consistent application of sustainability standards to new development projects

Sustainability standards are particularly relevant for Implenia when working on the projects it has developed itself, such as Lokstadt in Winterthur, Tivoli in Neuchâtel and Unterfeld in Baar. With these projects, the company can determine the location, architecture, construction and energy concept at an early stage, meaning that it can have an influence on the factors that are most relevant to the sustainability of a building – in the construction phase, in the operating phase and right through to eventual decommissioning. Implenia uses this leverage to set the highest possible standards for its own development projects. “We have stipulated that half our projects in Switzerland must be certified under the Swiss Sustainable Construction Standard (SNBS),” says Rolf Wagenbach, Global Head Sustainability. Consequently, a process was set up with the Real Estate Division in 2021 to ensure that new development projects meet SNBS criteria. A similar process is to be introduced in the German market in 2022 based on the Effizienzhaus standard.

Accurate analysis to reduce emissions

Implenia also wants to exert a positive influence on the consumption of grey energy, the use of renewable energies, water consumption and waste generation within its own development projects. Step one in the effort to continuously reduce emissions and increase the share of renewable energy was the analysis conducted in 2021 of the entire Real Estate portfolio, which currently includes 16 projects and 46 buildings in Switzerland. The analysis resulted in a list showing each project’s profile in three categories: construction, operation and mobility. Targeted measures are being defined on the basis of these profiles. In this way Implenia is creating an important foundation for the development, construction and operation of future “Net Zero Carbon Buildings”.

Group-wide collection of ideas for project-specific sustainability concepts

Global Sustainability also put in the groundwork for another goal: proactively offering customers project-specific sustainability concepts. “Implenia has many years of experience in the field of sustainability and can reference a large number of projects and concepts. Good solutions have been documented across the entire Group and made available internally,” says Rolf Wagenbach. “The aim is to provide a pool of options that can be incorporated into new projects.” The Real Estate Consulting unit is also trying to integrate sustainability concepts into customer projects as early as possible in the process.

Many small measures lead to a large reduction in CO2

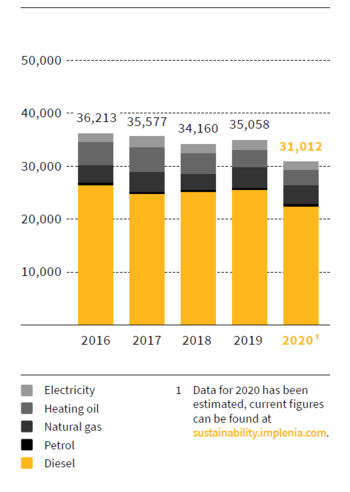

Implenia is constantly initiating and implementing measures to achieve net zero CO2 emissions by 2050, and reduce Group-wide CO2 emissions by 15% by 2025. Implenia has been developing solutions for emission-free construction sites in Norway, for example, since 2021 in partnership with clean-tech firm Teco 2030. Teco 2030 specialises in hydrogen fuel cells for marine applications. Further measures that help cut CO2 emissions include making concrete on site, which reduces lorry journeys, and decreasing the time equipment is left on stand-by. Implenia is also working on measures to promote sustainable supplier management.

Environmental incidents are systematically recorded throughout the group

An important step towards even more professional environmental management was taken in 2021 with the Group-wide introduction of Synergi Life. This is a tool that systematically records not only accidents involving people, but also environmental incidents, assigning them to five categories according to their severity. Category 1 covers environmental disasters, while category 5 is for incidents with minor consequences. Rolf Wagenbach: “The introduction of Synergi Life gives Implenia the data it needs to define measures that prevent environmental incidents or at least reduce their size.”

Initial projects and strategic work to close material cycles

Implenia believes that closing material cycles has great potential to reduce CO2 emissions in the construction industry and save primary resources. The company intends to develop new circular business models by 2025. At the same time as preparing a strategy for a Group-wide circular economy, various bottom-up initiatives are already being implemented. These include efforts by the Real Estate Products business unit, which is developing scalable, industrially manufactured real estate products based on far-reaching circularity principles and thus helping to close material cycles. The circular philosophy is also finding its way into the overhaul of the Waldenburg railway and other major civil engineering infrastructure projects: Implenia is using a semi-mobile gravel plant, in which excavated material is washed, sorted and then reused on site. Shorter transport routes reduce CO2 emissions and costs.