Bodio & Faido sections, Alptransit Gotthard Base Tunnel

Short description

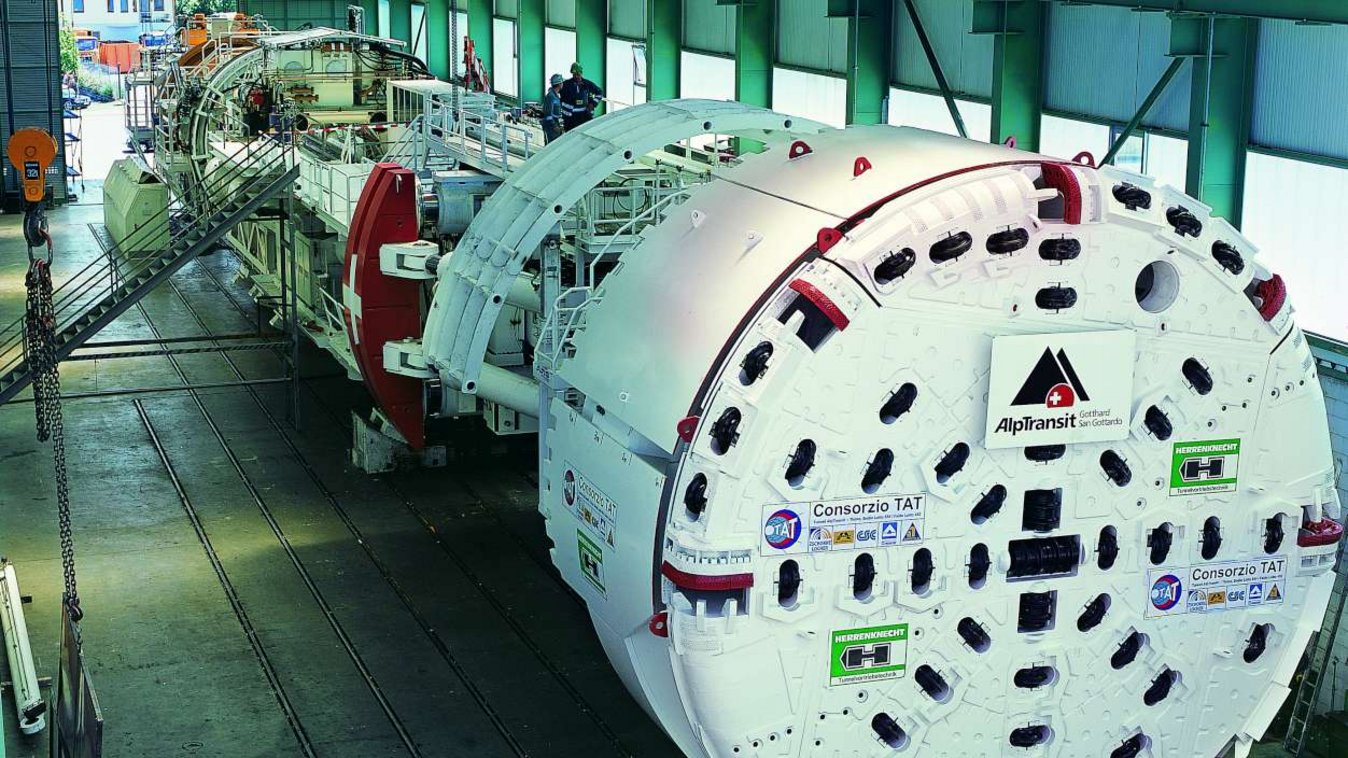

Construction of two parallel single-track railway tunnels with a Gripper TBM and of a multi-function station using blasting

The project

- Context: The Gotthard Base Tunnel (GBT; German: Gotthard-Basistunnel, Italian: Galleria di base del San Gottardo, Romansh: Tunnel da basa dal Son Gottard) is a railway tunnel through the Alps in Switzerland. It opened on 1 June 2016, and full service began on 11 December 2016. With a route length of 57.09 km (35.5 mi), it is the world's longest railway and deepest traffic tunnel and the first flat, low-level route through the Alps.

- Bodio: Railway tunnel with two parallel single-track tunnel tubes, each 30 km in length (57 km in total), cross-passages every 300 m. Shell construction: excavation, securing and interior construction.

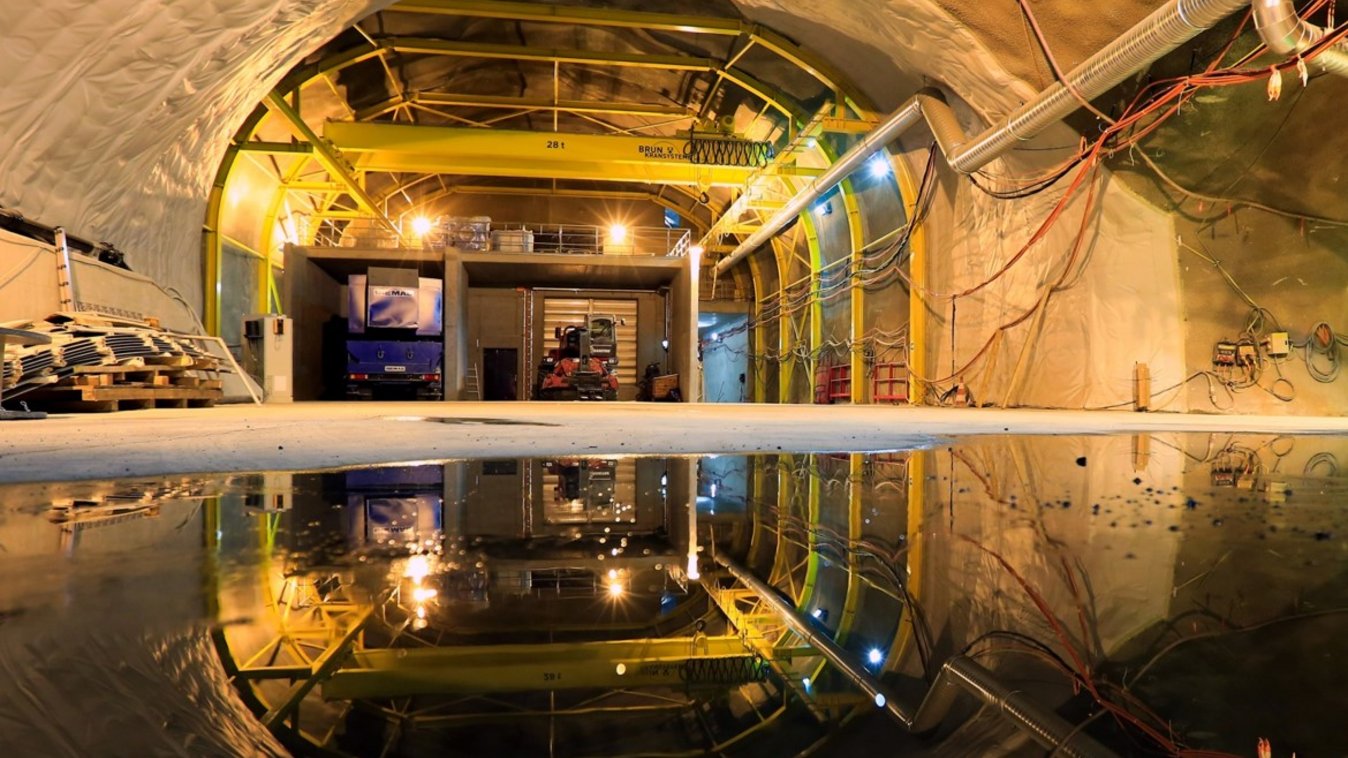

- Faido: Excavation, securing and interior construction of the 2.5-kilometre-long multi-function station (MFS) at Faido (with track changeover for the eastern/western tunnel tubes, emergency stop stations with exhaust air systems and escape tunnels, caverns for technical equipment).

Services in detail

- Bodio: The two single-track tunnels were excavated using tunnel boring machines (Gripper TBM). The section from the Bodio portal to the multi-function station (MFS) in Faido is approx. 15.5 km long and is situated in the Pennine gneiss zone. The section from the Faido MFS to the Sedrun sub-section is approx. 11 km long and traverses the Piora syncline and the Gotthard massif.

- Faido: The multi-function station at Faido (9.6 km of tunnels in total, including 2 track changeovers) was excavated using blasting. The interior is constructed from in-situ concrete and shotcrete.

- Shell equipment: Equipment of ancillary structures of the Gotthard Base Tunnel. This includes planning, manufacture, delivery, installation, commissioning and start-up of tunnel and railway technology.

Further information

Bodio:

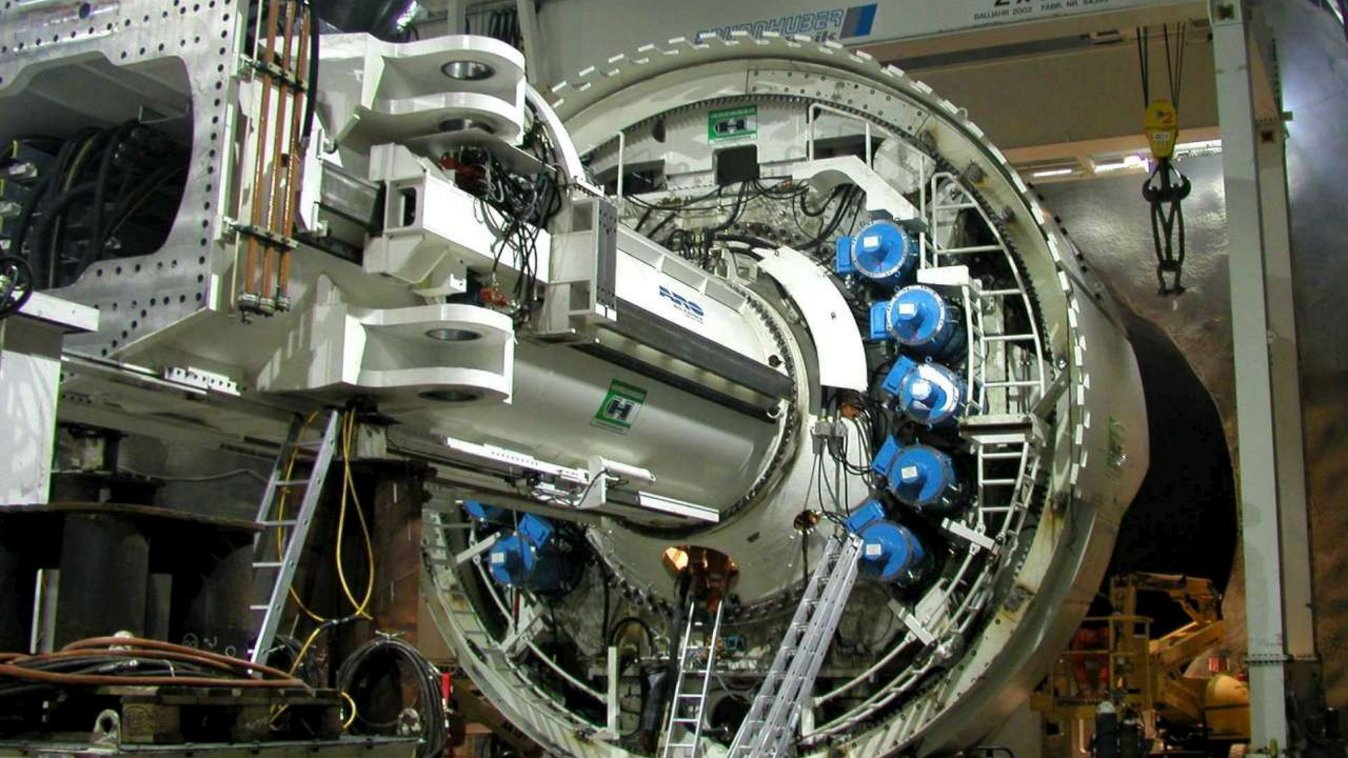

- Gripper TBM (an open tunnel boring machine for hard rock) with track-mounted material removal system.

- TBM used for boring in areas with convergences, unstable working face, seismic disturbances, and rock fall, with injections and boring in the opposite direction from the neighbouring tunnel tube.

- Exploratory boring with preventers for protection, cooling of underground workspaces.

- Interior construction (tunnel lining) in parallel with TBM operation –> use of special equipment (worm gear).

Faido:

- 6 parallel tunnelling sites (blasting).

- Various disturbance zones, squeezing rock zones, radial convergences of up to 1 m, seismic disturbances.

- Use of flexible steel structures due to squeezing rock.

- Use of emulsion explosives (pumped).

- Access via a 2700-metre-long tunnel with a gradient of 13%.

- Crushing plant in MFS, material removal via access tunnel.

- In-situ concrete tunnel lining in tunnel branch caverns (continuous profile expansion) with special formwork (lining with waterproofing & reinforcement).

- Methane gas levels, including deflagration, were measured in the crystalline rock during the excavation work.

Shell construction equipment:

- Installation of electrical systems 50 Hz and earthing.

- Installation of the control technology and the head computer.

- Planning and construction of the operational and event ventilation.

- Various steel construction measures for the interior fittings such as railings, crane systems, doors and gates.

- Installation of the fire protection bulkheads.